Amorphous alloy oil immersion type distribution transformer body structure and manufacturing method thereof

A technology of distribution transformers and amorphous alloys, applied in the direction of transformers/inductor coils/windings/connections, etc., can solve problems affecting the cost performance of amorphous distribution transformers and restrict the promotion and application of amorphous distribution transformers, and achieve low material cost, The effect of reducing copper resource consumption and low no-load loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

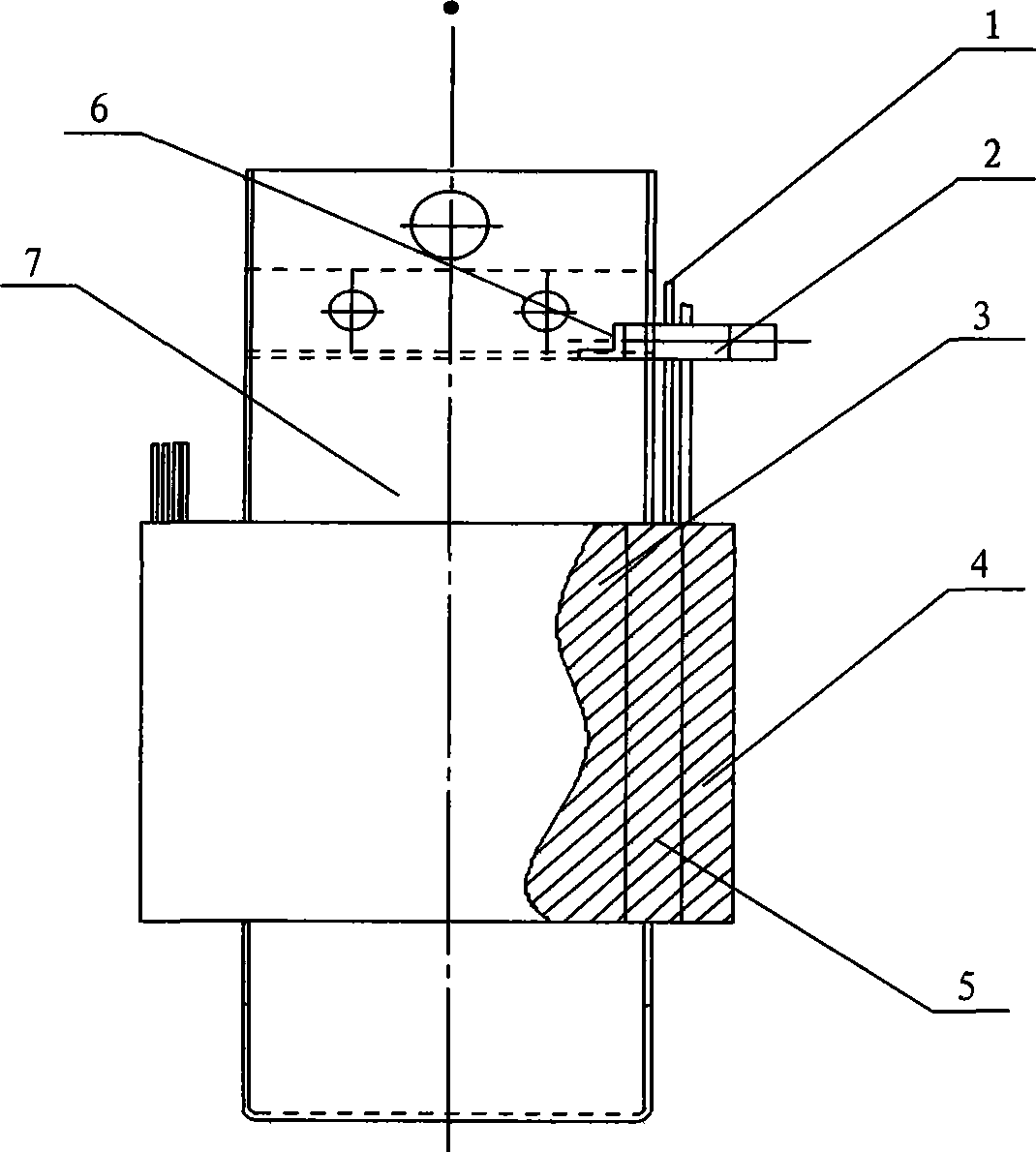

[0025] see figure 1 A method for manufacturing an amorphous alloy oil-immersed distribution transformer, one of the present invention, comprises the following steps:

[0026] The first step is to manufacture the amorphous alloy iron core 7 by winding. The iron core 7 can adopt a four-frame and five-pillar or three-frame and three-pillar structure with a rectangular cross-section, and is composed of one or two rows of amorphous alloy cores;

[0027] In the second step, a rectangular insulating frame 3 is set in the low-voltage coil 4, and the inner diameter of the insulating frame 3 should match the cross-sectional size of the iron core 7, and the low-voltage coil 4 is directly wound on the insulating frame 3, and the low-voltage coil 4 The number of layers is the number of turns, and the turns are separated by interlayer insulating paper (not shown in the figure);

[0028] The third step is to wrap the main insulation (not shown in the figure) on the outer surface of the low-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com