Glare-proof film, glare-proof polarizing sheet and image display device

An anti-glare polarizer and anti-glare film technology, which is applied in the direction of identification devices, polarizing elements, nonlinear optics, etc., can solve the problems of insufficient anti-glare performance, whitening of the display surface, and difficulty in obtaining it, so as to prevent visible Reduced performance, high anti-glare performance, and enhanced strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0106] (A) Preparation of polarizing film

[0107] A polyvinyl alcohol film with an average degree of polymerization of about 2400, a degree of saponification of 99.9 mol % or more, and a thickness of 75 μm was immersed in pure water at 30° C., and then immersed in iodine / potassium iodide / water at a mass ratio of 0.02 / 2 / 100 in aqueous solution. Thereafter, it was immersed in an aqueous solution having a mass ratio of potassium iodide / boric acid / water of 12 / 5 / 100 at 56.5°C. Next, after washing with 8° C. pure water, it was dried at 65° C. to obtain a polarizing film in which iodine was adsorbed and oriented on polyvinyl alcohol. Stretching is mainly carried out in the process of iodine dyeing and boric acid treatment, and the total stretching ratio is 5.3 times.

[0108] (B) Production of anti-glare film

[0109] An ultraviolet curable resin composition in which the following components were dissolved in ethyl acetate at a solid content concentration of 60% was prepared.

...

Embodiment 2 and comparative example 1

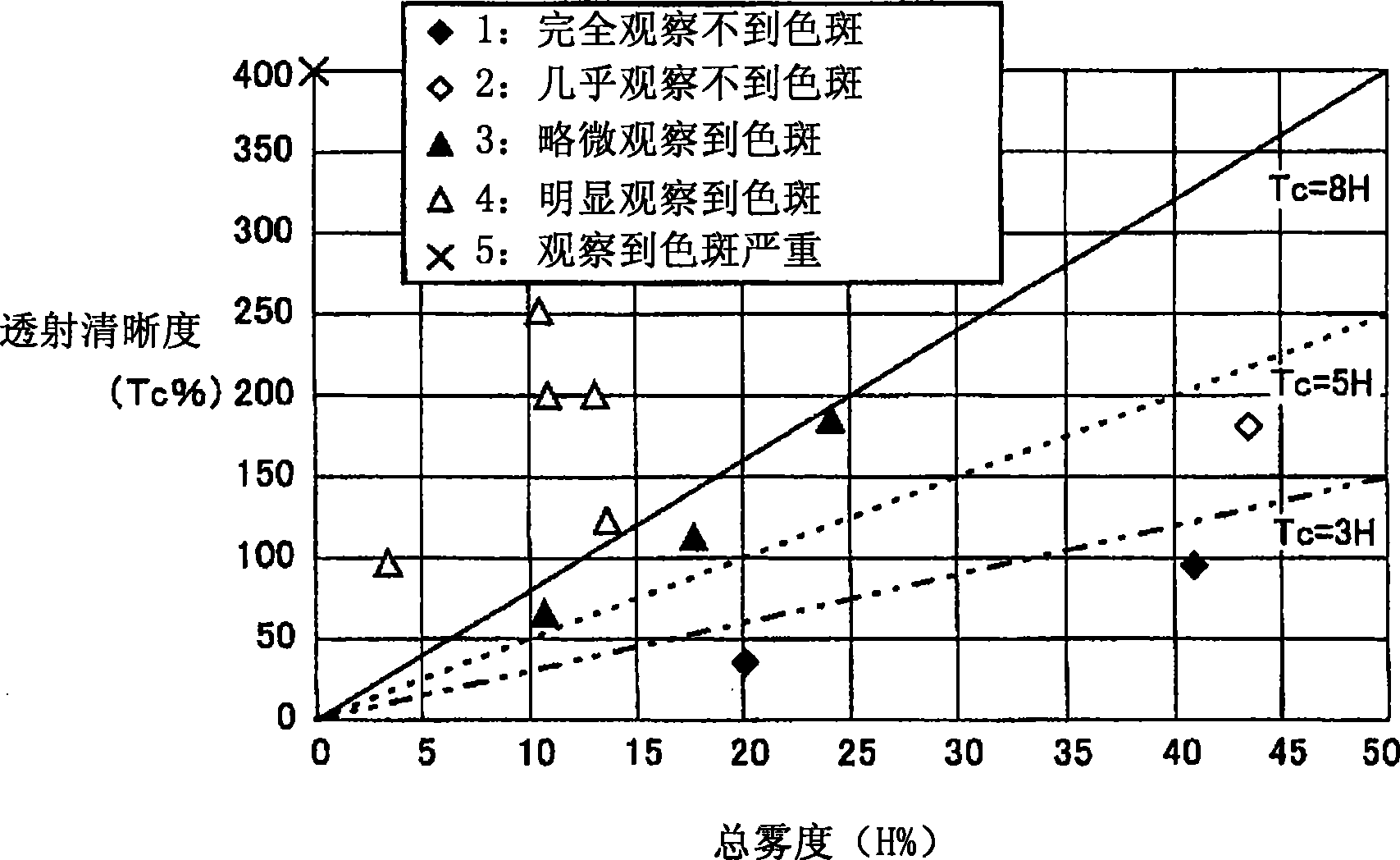

[0127] The parts by weight of the filler (porous silica particles, simply referred to as "silicon dioxide" in Table 1) dispersed in the coating liquid were changed as shown in Table 1, and the same procedure as in Example 1 was performed except that , making an anti-glare film, and evaluating the optical properties. Table 2 describes the evaluation results of optical properties.

Embodiment 3~5 and comparative example 2 and 3

[0129] Instead of porous silica particles, the filler dispersed in the coating solution was changed to spherical polystyrene particles (refractive index 1.59) with a weight average particle diameter of 3.0 μm, and the added weight parts and anti-glare layer thickness are shown in Table 1 Except having changed as shown, it carried out similarly to Example 1, the anti-glare film was produced, and the optical characteristic was evaluated. Table 2 describes the evaluation results of optical properties.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Weight average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com