Water injection technological process using three parameters test curve for layered pulling and running for water injection allocation

A process method and three-parameter technology, applied in the directions of surveying, earthwork drilling, and mining fluids, etc., can solve the problems of slow formation energy recovery, high labor intensity, and long construction period, so as to achieve true data, improve pass rate, and save manpower Material effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0088] It took 4 days to complete the water diversion construction of the well, saving 2-4 days than before. Embodiment 2, West 37-0 well, the oil well is converted into a separate injection well (applicable to water exchange wells and new separate injection wells)

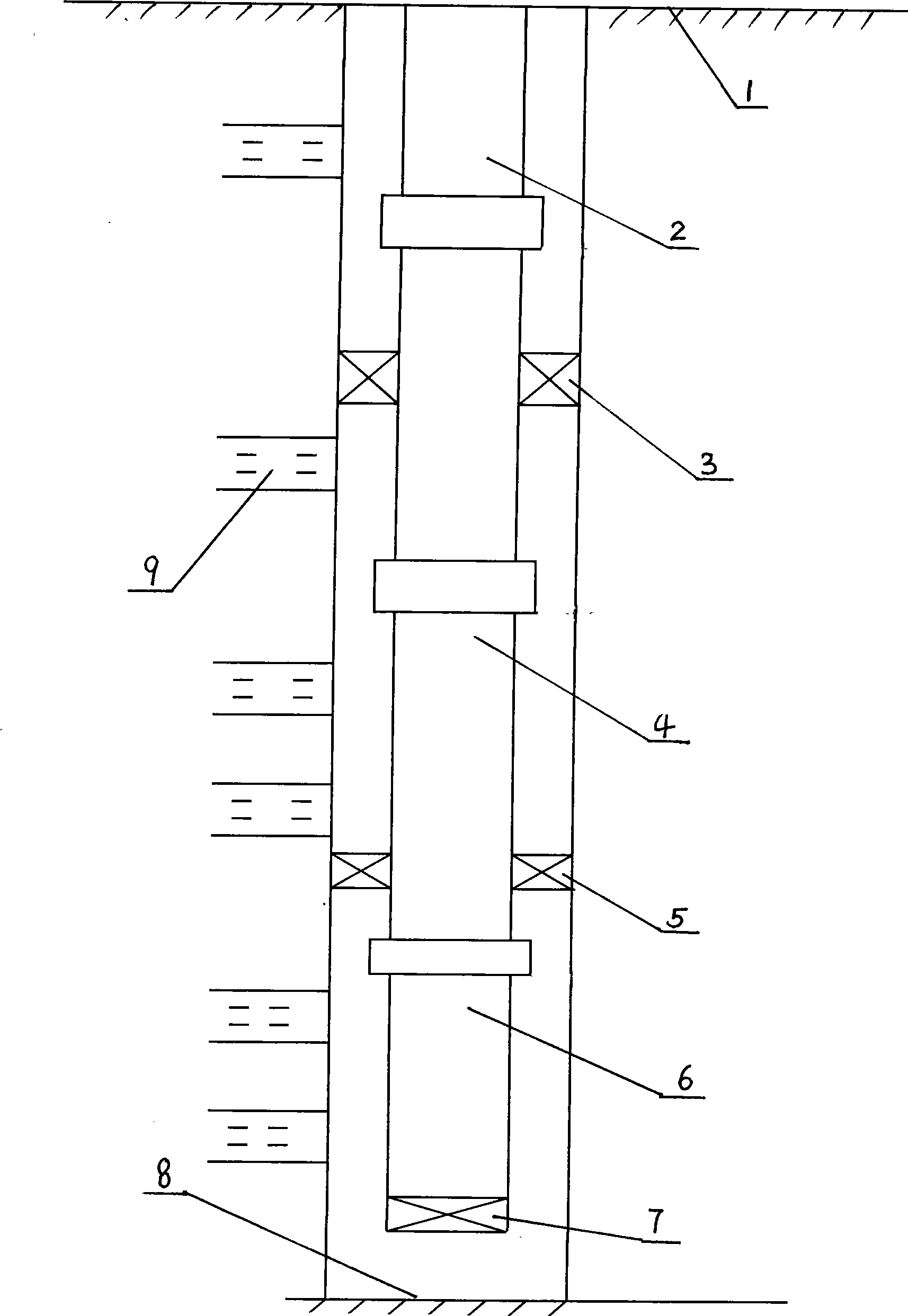

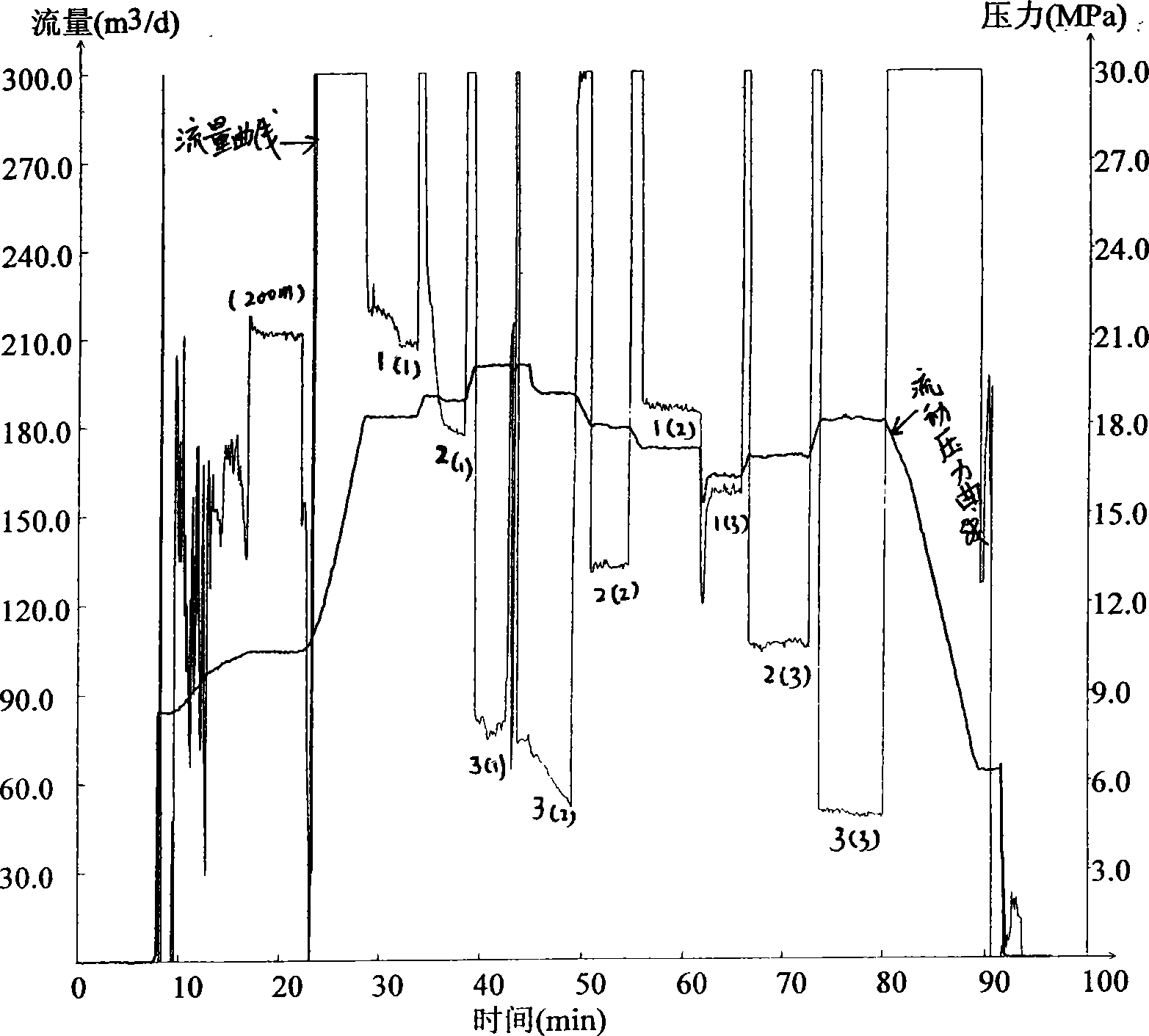

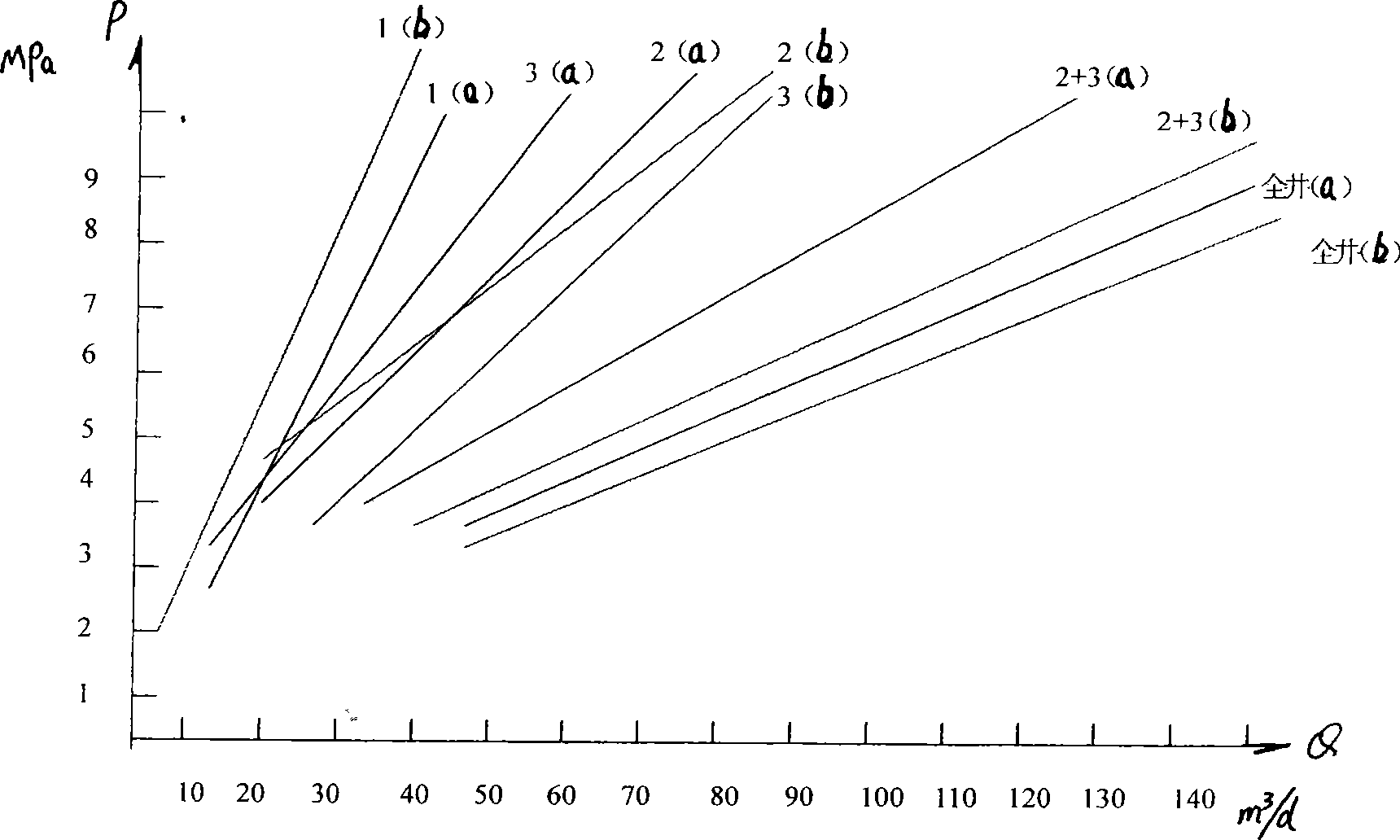

[0089] West 37-0 is an oil well that is directly transferred to separate injection wells. The pipe string structure is two-stage and three-stage water injection. According to the steps of the water exchange method in the method of the present invention, firstly, the water injection is distributed according to the whole well, and the formation energy is restored for 6 days. The pressure reaches 4.8MPa, and the formation is stable. Use three points to test the water volume, and follow the first to seventh steps of the water exchange method to measure the stratification test curve before injection, such as Figure 5 shown; according to the measured data, draw the three-parameter layered indication curve before dispen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com