Process for producing thermoplastic elastomer composition foam body, and thermoplastic elastomer composition for foam injection molding

A technology for thermoplastic elastomers and manufacturing methods, which is applied in the field of manufacturing thermoplastic elastomer composition foams and thermoplastic elastomer compositions for foam injection molding, and can solve the problem of uneven size and shape of foaming units and decreased flexibility , large foaming unit, etc., to achieve excellent uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0157] (Preparation of thermoplastic elastomer composition)

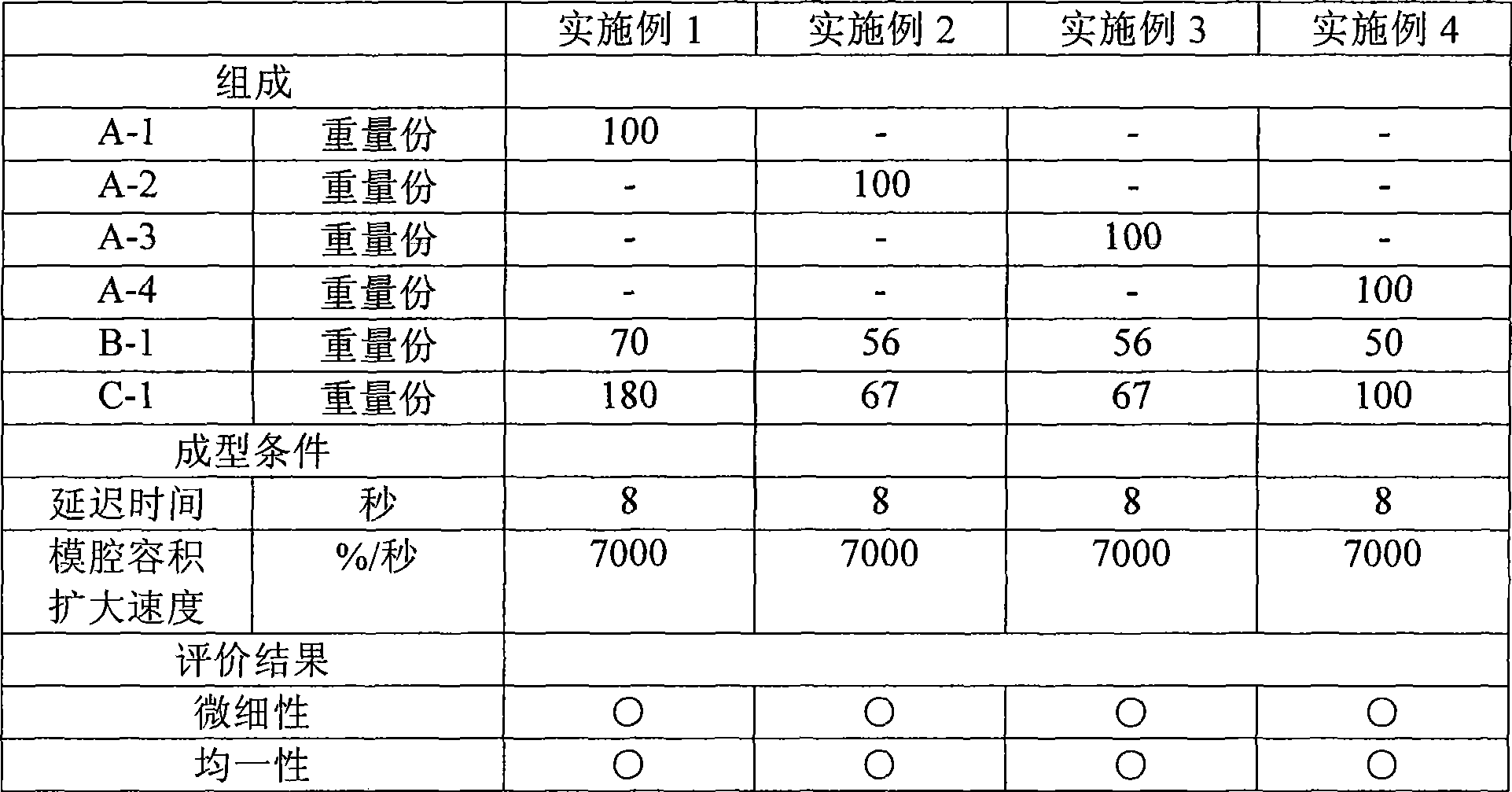

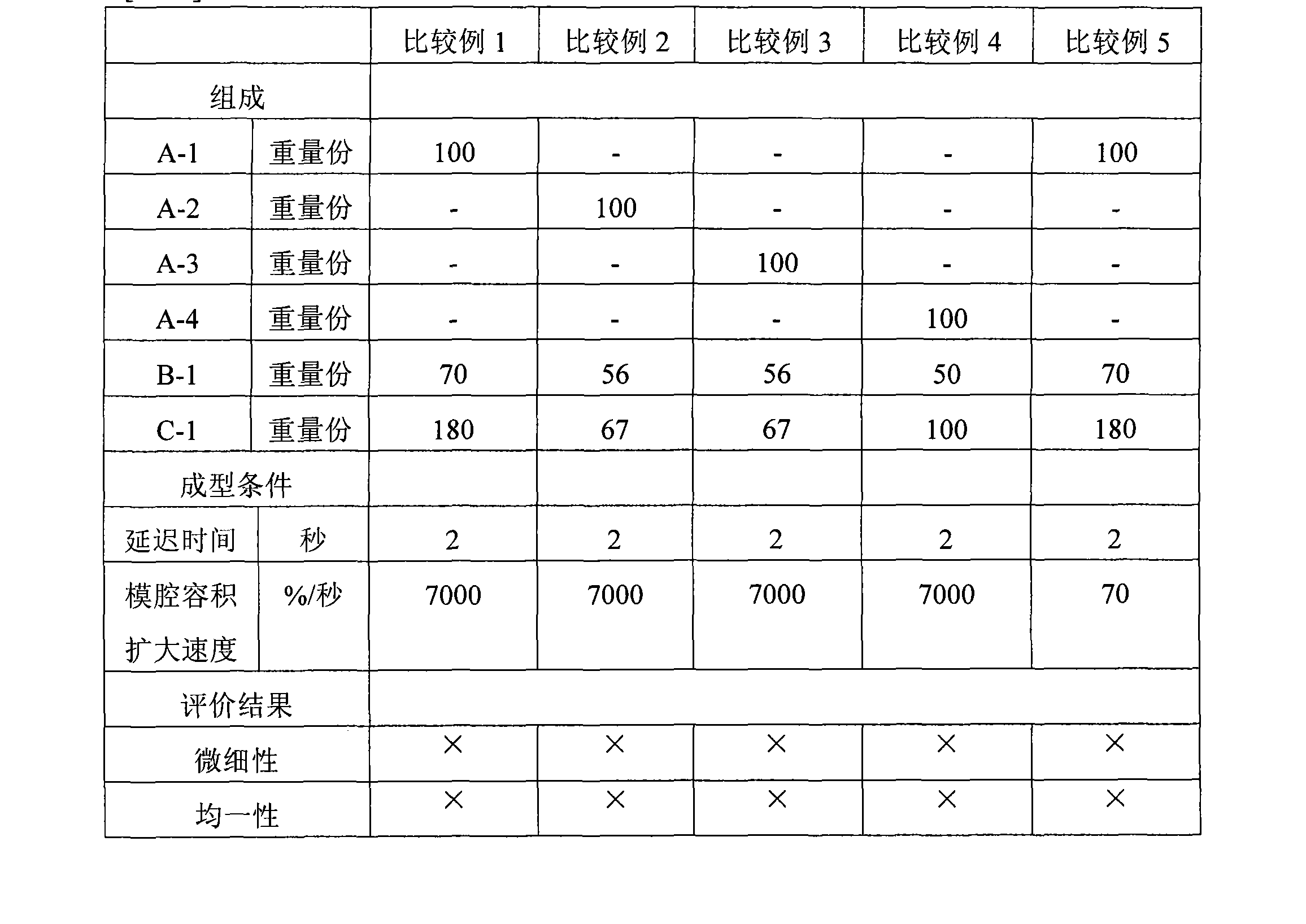

[0158] 100 parts by weight of hydrogenated styrene-conjugated diene-styrene block copolymer of A-1, 70 parts by weight of B-1 acrylic resin to 1100 parts by weight of A-1100 180 parts by weight of C-1 mineral oil, 0.05 parts by weight of erucamide (NEUTRON S (trade name) manufactured by Nippon Seika Co., Ltd.) ), 0.05 parts by weight of calcium stearate and 0.15 parts by weight of antioxidant (0.1 parts by weight of IRGANOX 1010 (trade name) manufactured by Ciba Specialty Chemicals Co., Ltd., 0.05 parts by weight of Ultranox 626 (trade name) manufactured by GE Specialty Chemicals) Melting and kneading in an internal mixer, and then molding into pellets to obtain pellets of a thermoplastic elastomer composition.

[0159] (Manufacture of foam injection moldings)

[0160]The injection molding machine adopts ES2550 / 400HL-Mu Cell (clamping force 400t) made by ENGEL Company. Body central part) mold for foam injection m...

Embodiment 2

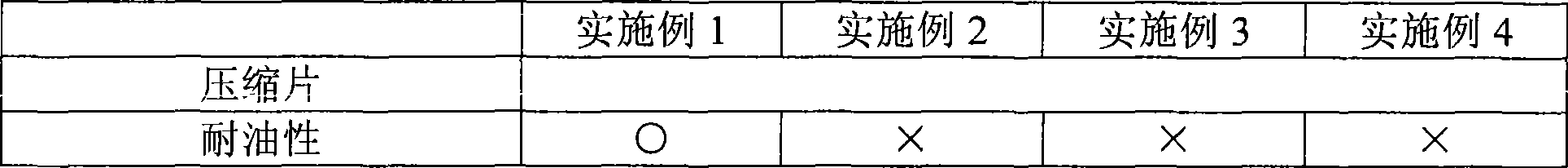

[0162] Replace the hydrogenated product of the styrene-conjugated diene-styrene block copolymer of A-1 with the hydrogenated product of the styrene-conjugated diene-styrene block copolymer of A-2 of 100 parts by weight, B -1 The propylene-based resin was 56 parts by weight with respect to 100 parts by weight of A-2, and the mineral oil of C-1 was 67 parts by weight with respect to 100 parts by weight of A-2. The evaluation results are shown in Table 1 and Table 2.

Embodiment 3

[0164] Replace the hydrogenated product of the styrene-conjugated diene-styrene block copolymer of A-1 with the hydrogenated product of the styrene-conjugated diene-styrene block copolymer of A-3 of 100 parts by weight, B -1 was 56 parts by weight of propylene-based resin with respect to 100 parts by weight of A-3, and the mineral oil of C-1 was 67 parts by weight with respect to 100 parts by weight of A-3. The evaluation results are shown in Table 1 and Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| force | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com