Resin composition and shaped foam article

A technology of resin composition and polymer beads, applied in the field of foam molding, can solve the problems of sticking of extrusion molding products, insufficient foamability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~7、 comparative example 1

[0127] After uniformly premixing the specified amount of each component shown in Table 1 in the drum, use a twin-screw mixing extruder (TEX44SS 30BW-2V type manufactured by Nippon Steel Works) to extrude at a rate of 30 to 50 kg The obtained premix was kneaded under vent suction at a screw rotation speed of 300 rpm, and the obtained kneaded product was extruded at an extrusion rate of 30 to 50 kg / hr to produce resin composition pellets.

[0128] Using the pellets, injection foam molding was performed using an injection molding machine ES2550 / 400HL-MuCell manufactured by ENGEL (400 tons of clamping force). As a blowing agent, nitrogen in a supercritical state is used.

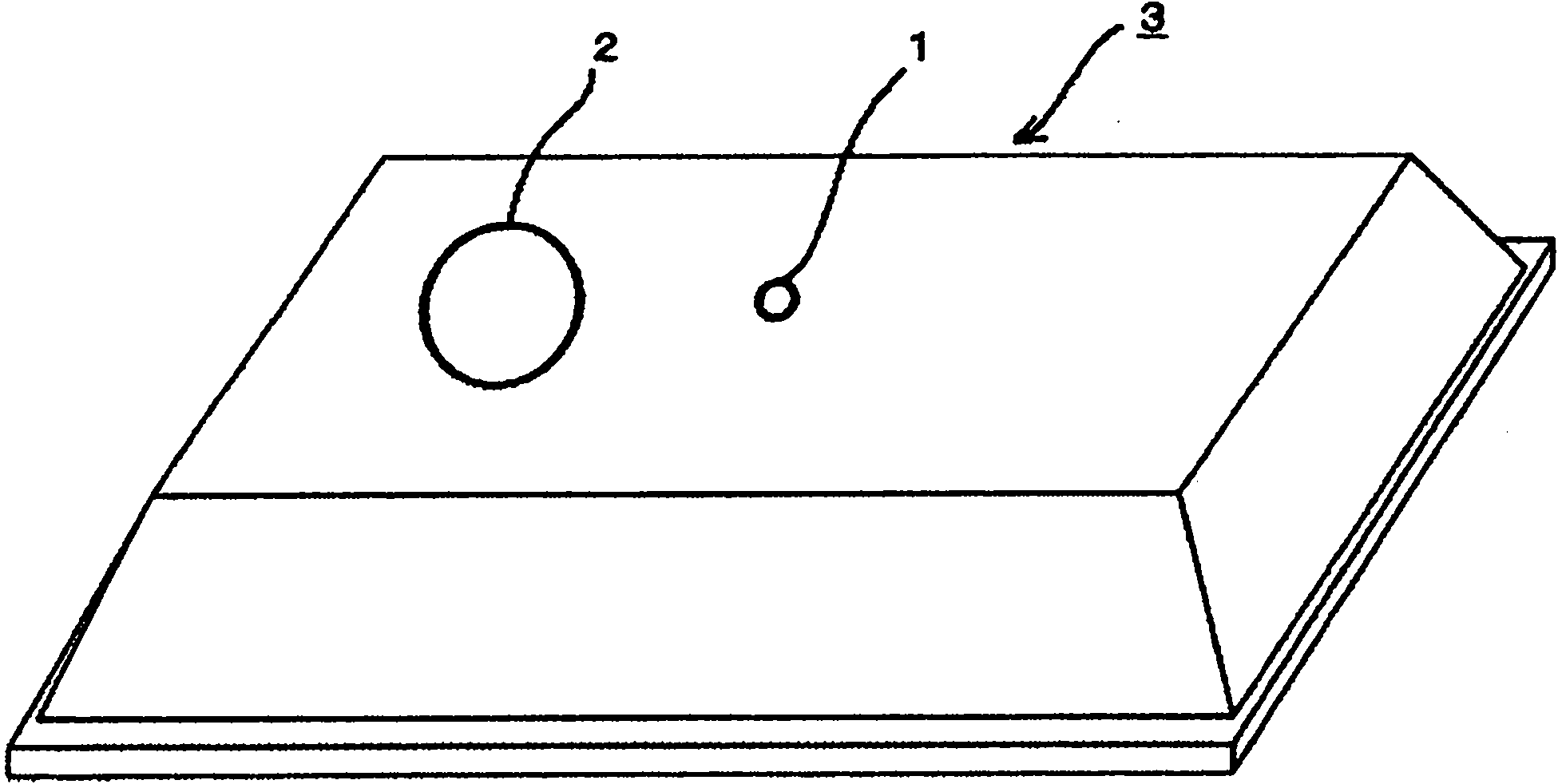

[0129] injection molding use figure 1A mold having a cavity corresponding to the shape of a molded body with approximate dimensions of 290 mm x 370 mm x 45 mm (height) shown in a schematic perspective view of . It should be noted that the basic cavity gap (initial plate thickness) of the above-mentioned cavity...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com