Non-impeller hollow screw axis centrifugal cavity pump

A technology with a hollow shaft and no impeller, applied in the field of centrifugal pumps, can solve problems such as low efficiency, complex structure, and many consumables, and achieve the effects of improved efficiency, high-quality materials, and low maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

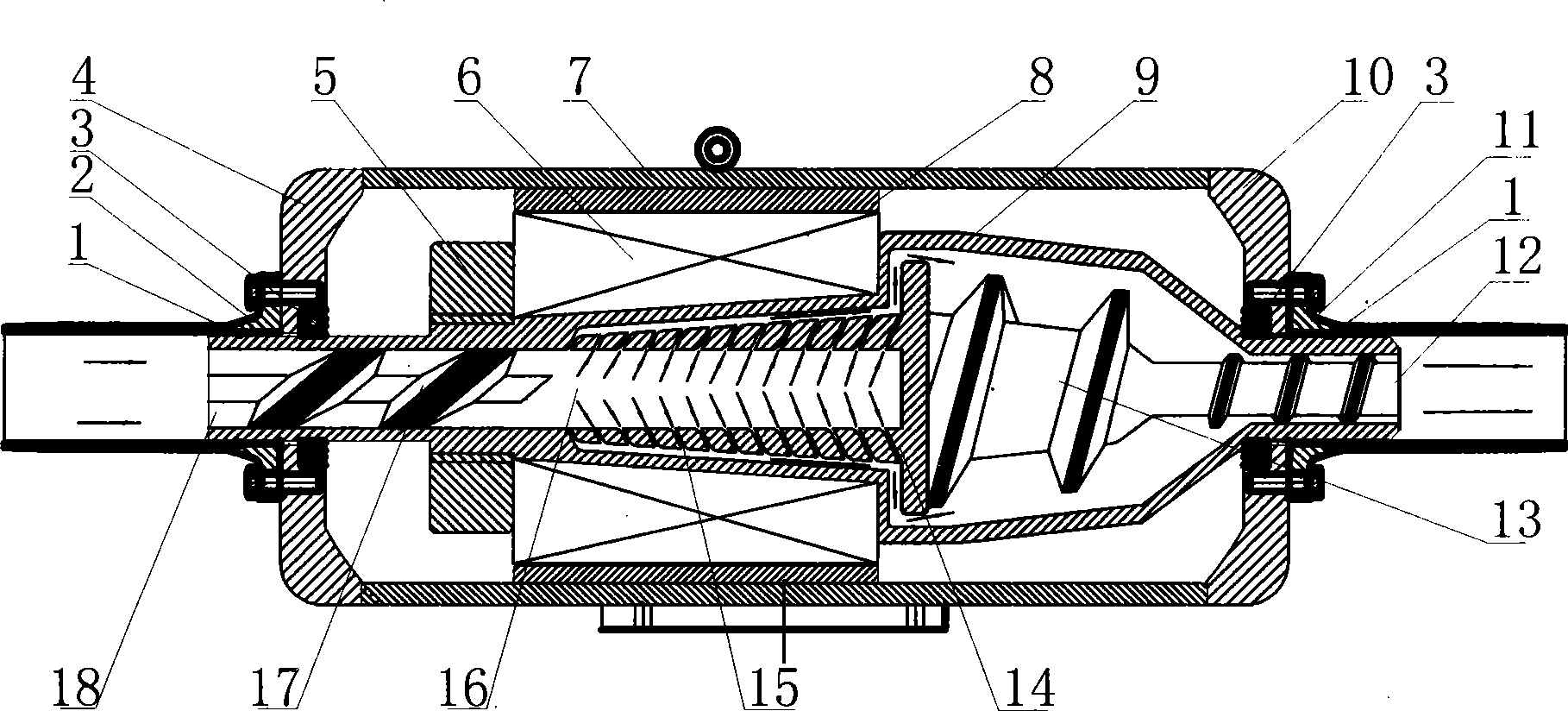

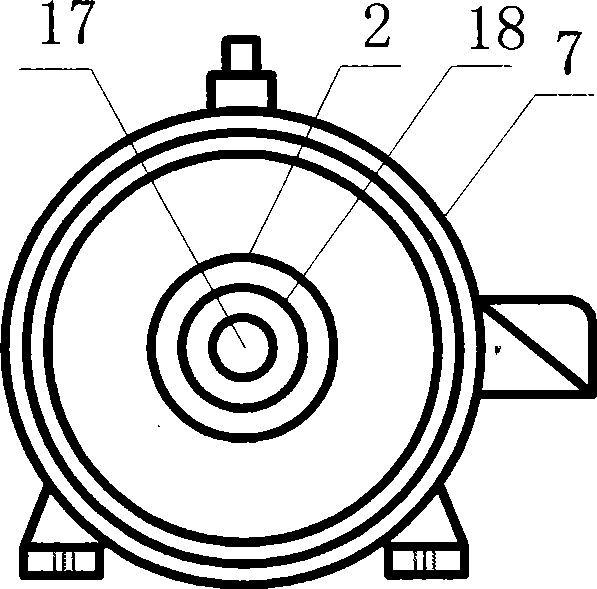

[0031] An impellerless hollow screw shaft centrifugal cavity pump, comprising a housing 7, a conical hollow shaft 9, a front helical guide body 17, a rear helical guide body 13, a water inlet pipe 2, a water outlet pipe 11, and a cavity cone 14 , the front end cover 4, the rear end cover 10, the rotor 6; the two ends of the housing 7 are respectively provided with front and rear end covers 4 and 10, and the centers of the front and rear end covers 4 and 10 are respectively provided with a central hole, and the center A bearing 3 is installed in the hole, and the front and rear end covers 4 and 10 are fixedly connected with the water inlet interface pipe 2 and the water outlet interface pipe 11 respectively by screws.

[0032] The shell 7 is equipped with a tapered hollow shaft 9, the two ends of the tapered hollow shaft 9 are respectively provided with a water inlet 18 and a water outlet 12, and the two ends of the tapered hollow shaft 9 are respectively provided with a sealing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com