Mildewproof powder for preventing glass surface from mildewing

A glass surface and anti-mildew powder technology, which is applied in the field of flat glass and anti-mold powder to prevent glass surface from mildew, can solve the problems of low cost, damage, scratches, etc., and achieve the effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] It is prepared from the following materials according to the ratio of parts by weight, polypropylene: acid anti-mold powder = 2:1;

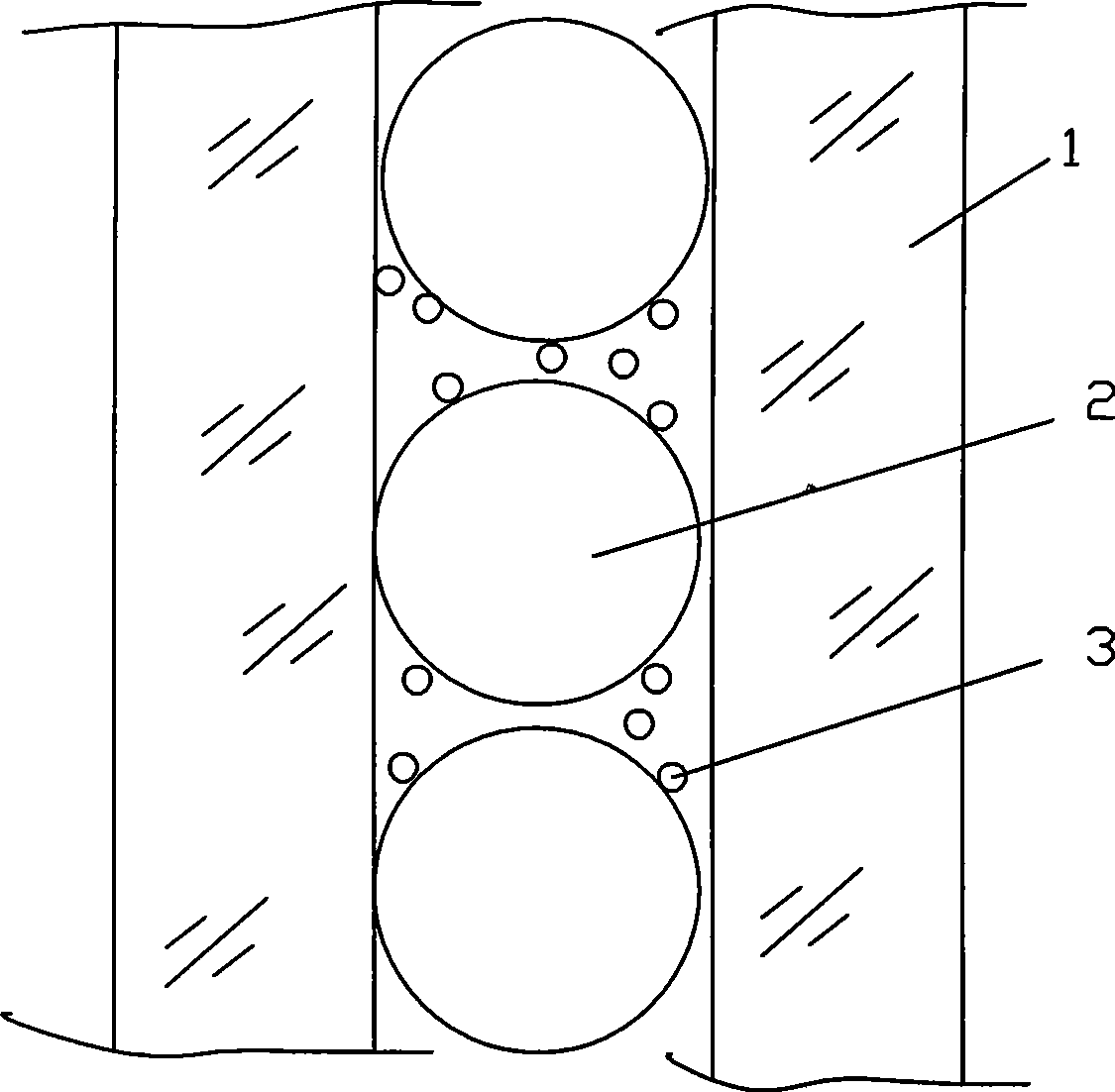

[0020] The polypropylene is cylindrical with a diameter of 90-120 μm;

[0021] The acidic anti-mildew powder is prepared from the following materials in parts by weight, benzoic acid: sorbic acid = 1:1.5; the particle size diameter of the acidic anti-mold powder is 60 μm.

[0022] The method of use is to evenly distribute it on the glass surface by roller dusting or electrostatic powdering.

Embodiment 2

[0024] It is prepared from the following materials according to the ratio of parts by weight: polyethylene:acid anti-mold powder=6:1; other is the same as in Example 1.

Embodiment 3

[0026] It is prepared from the following materials according to the ratio of parts by weight: polymethyl methacrylate: acid anti-mildew powder = 4:1. Others are with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Particle size diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com