A Dielectric Barrier Discharge Low Temperature Plasma Harmful Gas Conversion Device

A low-temperature plasma and dielectric barrier discharge technology, which is used in the field of plasma device conversion of industrial waste gas and harmful emissions from motor vehicles, and environmental protection, can solve the problems of restricting the continuity of harmful gas treatment, low efficiency, and poor temperature tolerance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

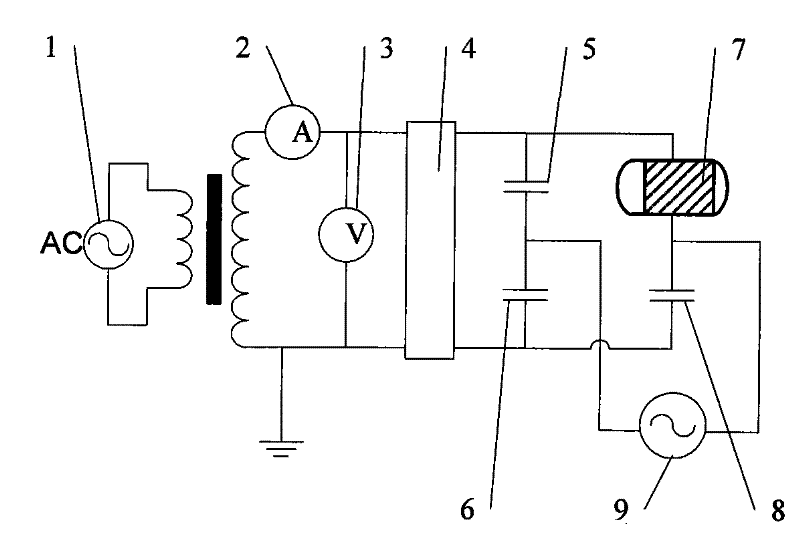

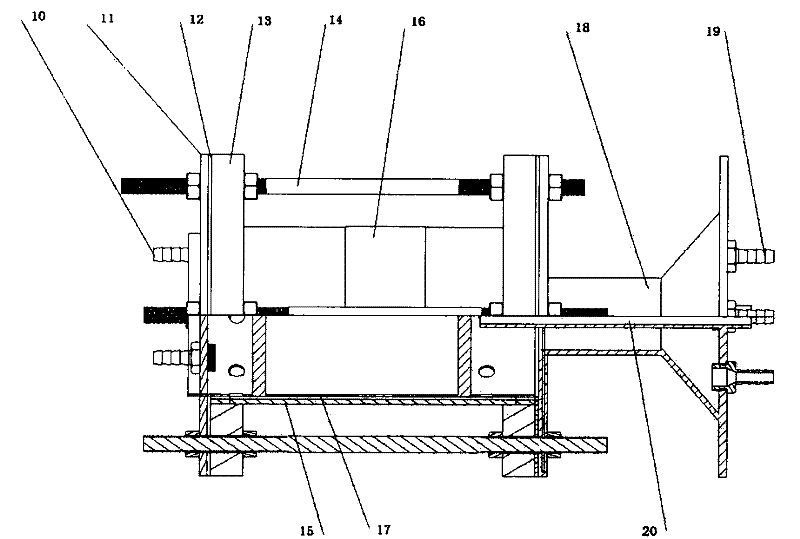

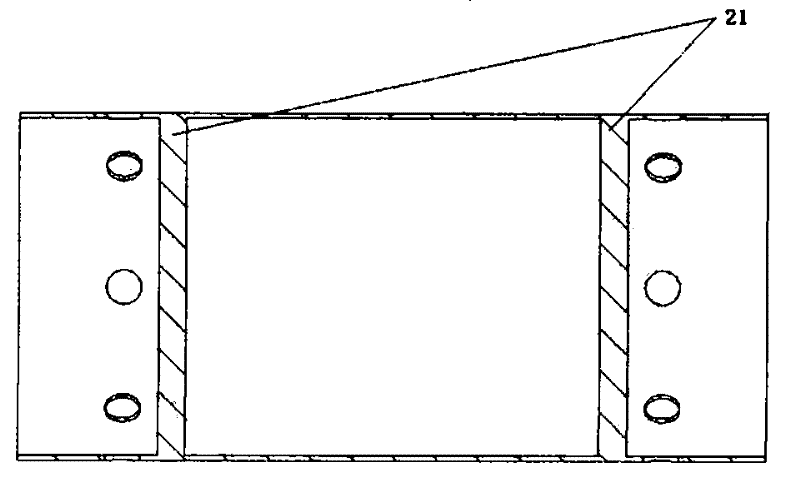

[0022] The invention is a device for generating low-temperature plasma by dielectric barrier discharge to treat harmful gases. In addition to using the device to generate ozone in the atmospheric environment, the device can also be used to treat toxic gases such as NO, HC, CO, organic waste gas, and PM. . combine Figure 1 ~ Figure 3 , the low-temperature plasma harmful gas treatment device of the present invention adopts a coaxial structure, the main part is composed of a central low-voltage electrode 17, a quartz medium 15 coaxial with it, and a high-voltage electrode 16 tightly wrapped on the outside of the medium, and the discharge channel is in the central low-voltage electrode. 17 and the discharge gap (1-3mm) inside the quartz medium 15. The structure of the central low-voltage electrode 17 made of stainless steel tubes is as follows: figure 2 As shown, the side walls at both ends are perforated, and the middle is sealed by a blocking plate 21. The high-voltage elec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com