Cable stayed bridge construction method

A construction method and technology for cable-stayed bridges, applied to cable-stayed bridges, bridges, bridge forms, etc., can solve the problems of long construction period and high construction cost, so as to reduce the construction period, ensure the safety of the tower column structure, and reduce wind vibration The effect of response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The construction method of cable-stayed bridge of the present invention may further comprise the steps:

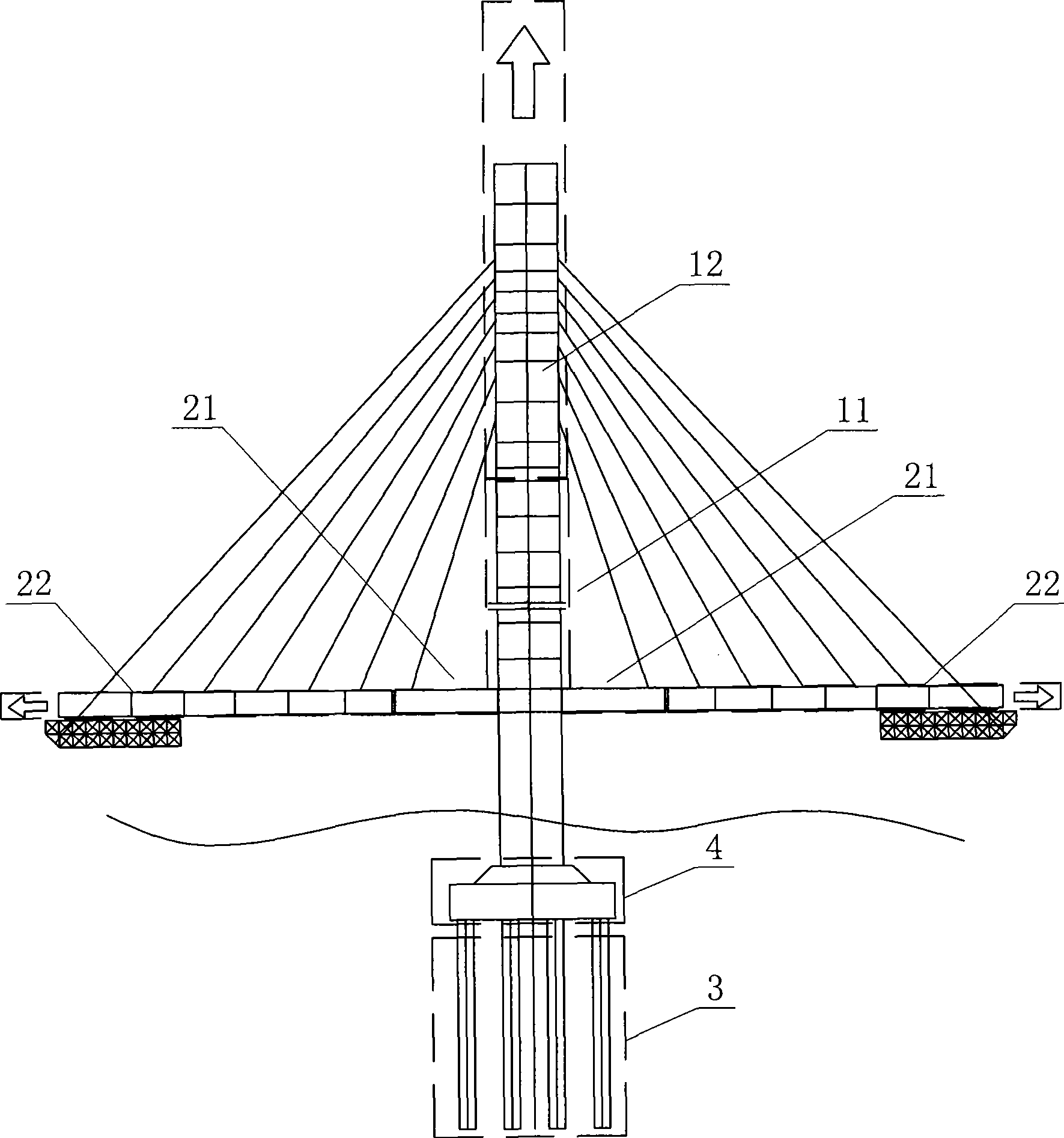

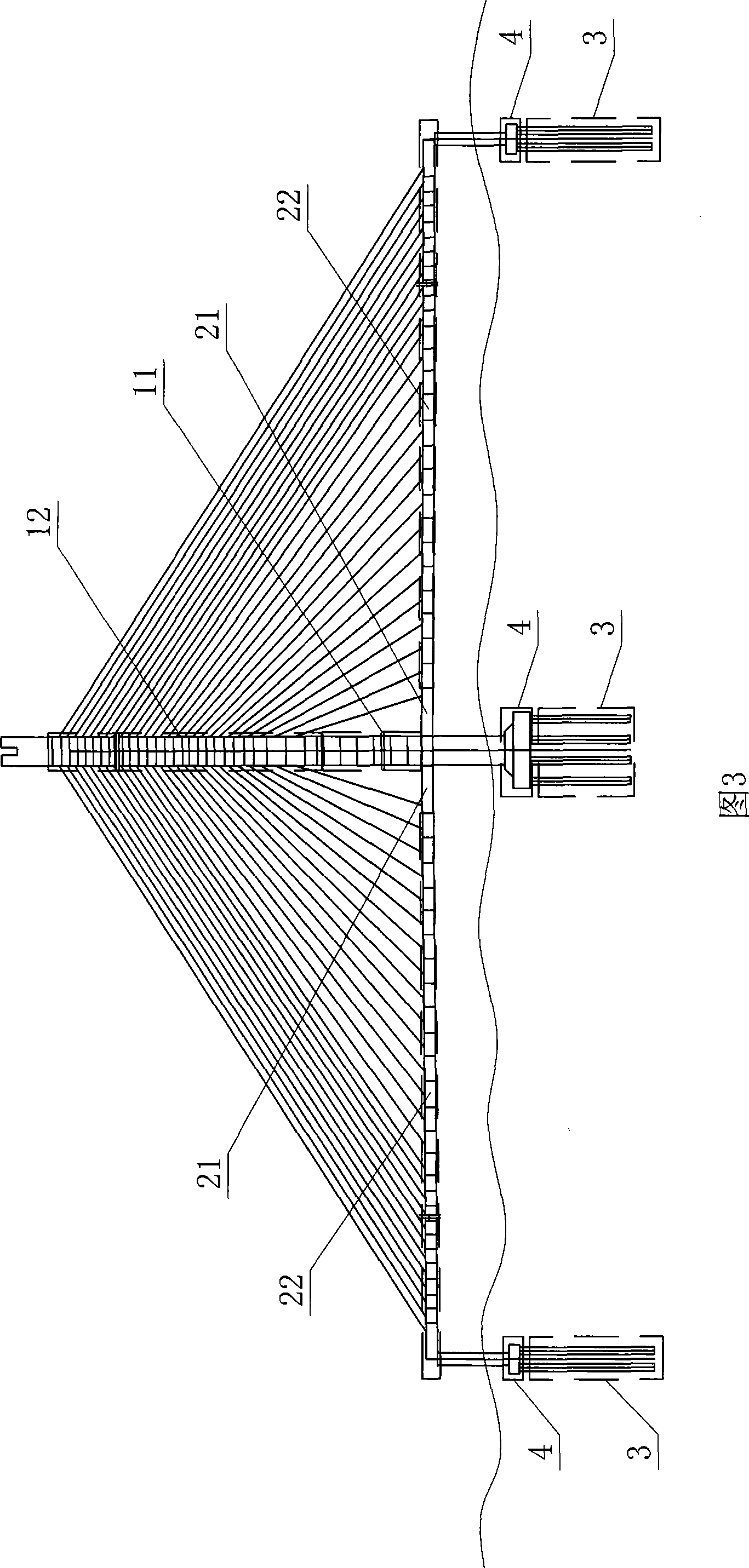

[0014] 1. After the bridge pile foundation 3 and the pile cap 4 are constructed, the non-cable area structure 11 of the main tower column is constructed first, and the main beam 0# is carried out while the non-cable area structure 11 of the main tower column is being constructed. Construction of block structure 21. The construction of the structure 11 in the non-hanging cable area of the main tower column can be completed in segments by using sliding formwork, climbing formwork or combined formwork, and the main beam 0# block structure 21 can be completed by cast-in-place support formwork.

[0015] 2. Then carry out the synchronous construction of the cable hanging area structure 12 of the main tower column and the main beam 22. That is, while the cable-hanging area structure 21 of the main tower column is being constructed vertically in sections, the main girder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com