Quick-speed clarification tank

A clarification tank, fast technology, applied in the direction of flocculation/sedimentation water/sewage treatment, etc., can solve the problems of small footprint of the clarification tank, limited increase in coagulation effect, increase in civil construction costs, etc., and achieve good water quality and water impact impact , Improve the effect of mud-water separation, and the effect of strong adaptability of processing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

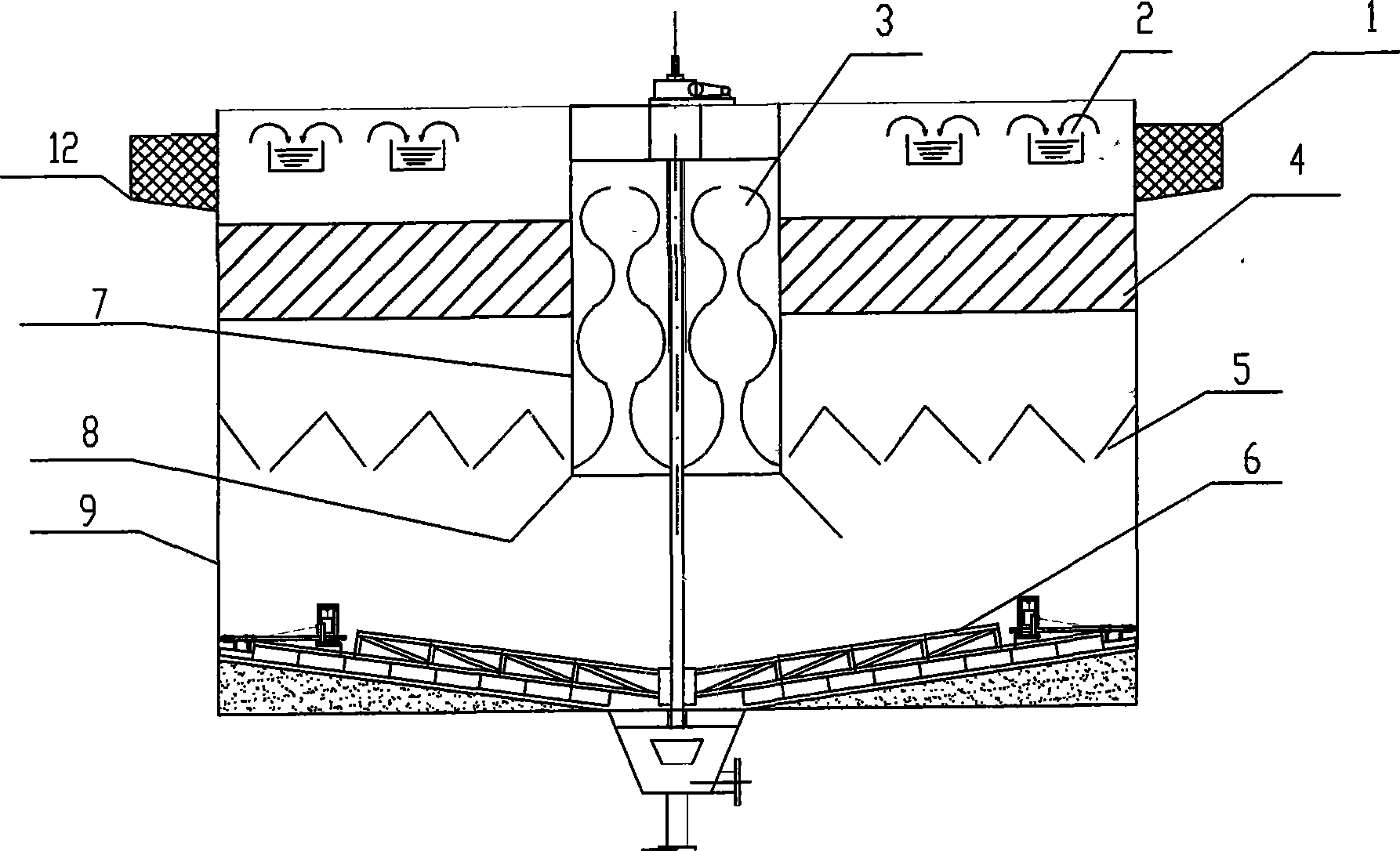

[0027] Embodiment 1: see figure 1 , 2 4. The rapid clarification tank of the present invention includes a square tank body 9 with a full cross-section up and down, a circular bottomless reaction chamber 7 suspended in the center, the cross-section of the reaction cylinder accounts for 2-5% of the cross-section of the clarification tank, and the reaction chamber has built-in side-by-side corrugated plates 3, There is an enlarged bell mouth 8 at the bottom of the reaction chamber, the bottom surface of the pool is conical, and there is a centrally driven rotary mud scraper 6 close to the bottom of the cone. There is an inclined plate or inclined tube separation device 4 in the area above the pool. A number of water outlet tanks 2 are connected to each other and discharged from the water outlet main pipe 11. There is a vortex reaction device 5 composed of alternate "herringbone" characters between the inclined plate (pipe) separation device and the rotary mud scraper (middle and...

Embodiment 2

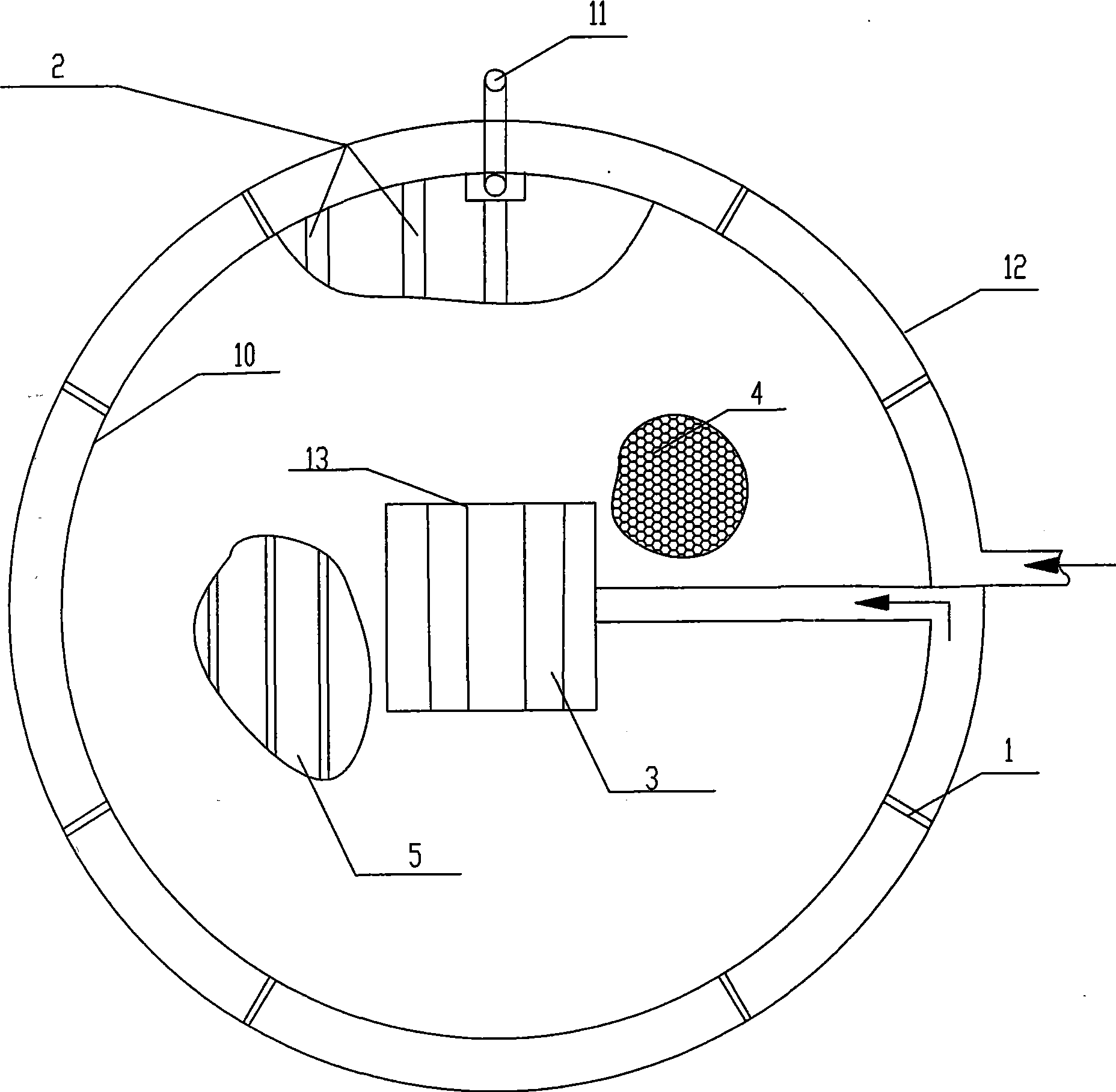

[0030] Example 2: see image 3 , As in the embodiment, the square tank body is changed to a circular tank 10 with a cross section, the central flocculation reaction chamber 13 has a square cross section, and the mud scraper is an ordinary circular central drive rotary mud scraper.

Embodiment 3

[0031] Embodiment 3: see Figure 5 , as mentioned above, wherein the interphase turbulence device in the coagulation reaction tank 12 is the interphase flap 26 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com