Stirring type corn yoghourt and preparation method thereof

A stirring type, grain technology, applied in food preparation, milk preparations, dairy products, etc., can solve the problem of not being absorbed by the human body, and achieve the effect of improving the rate of hot water exudation, stable product quality, and expanding consumer groups.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

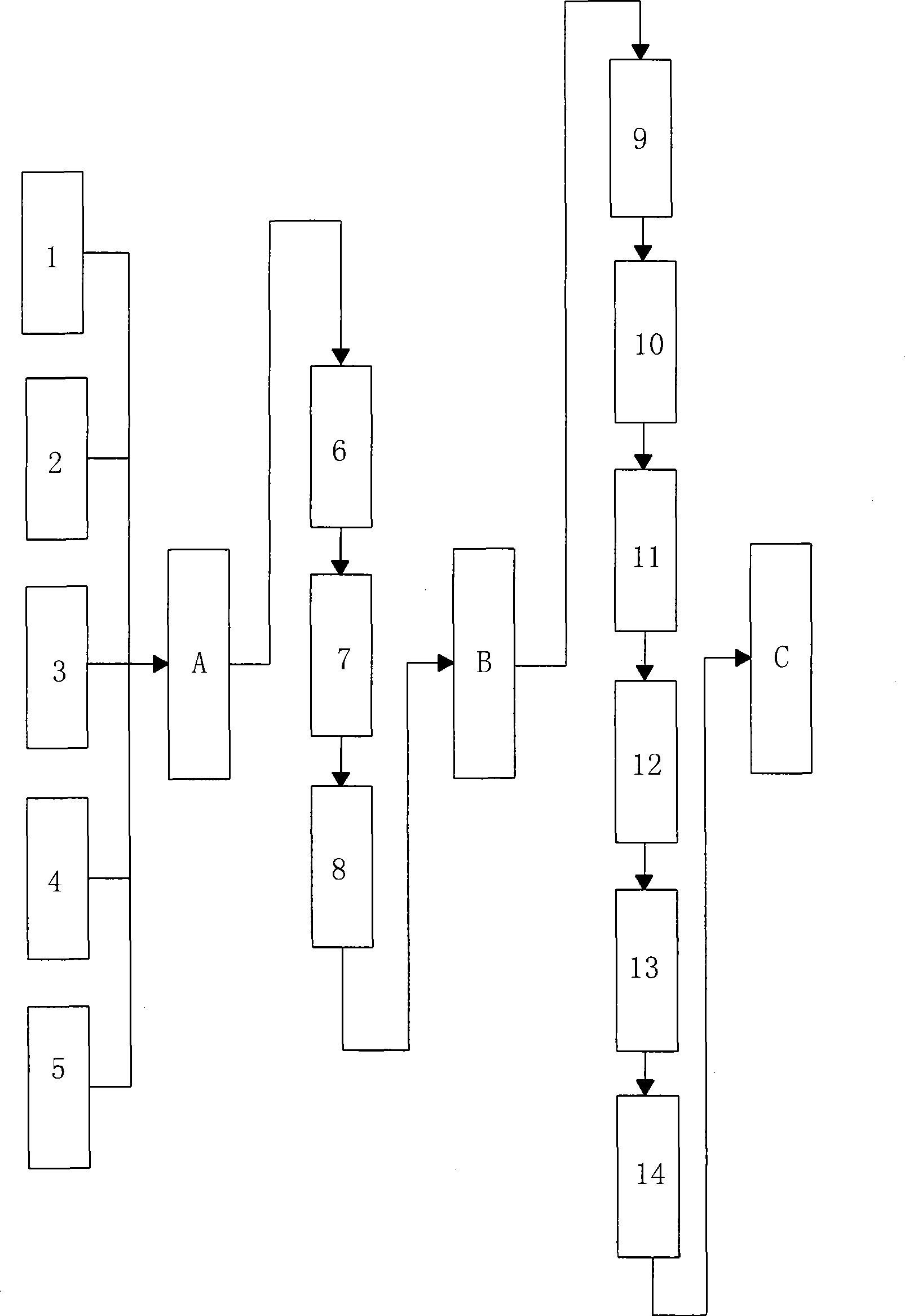

Method used

Image

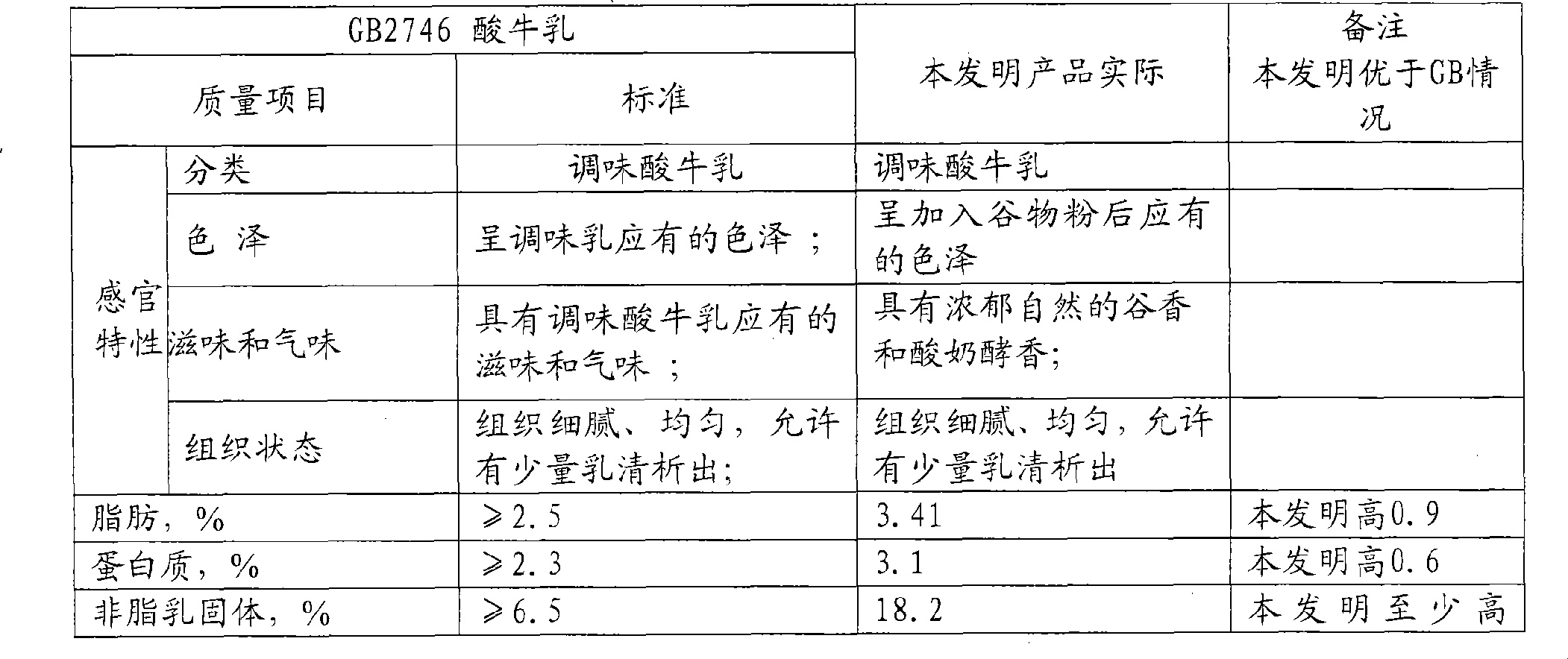

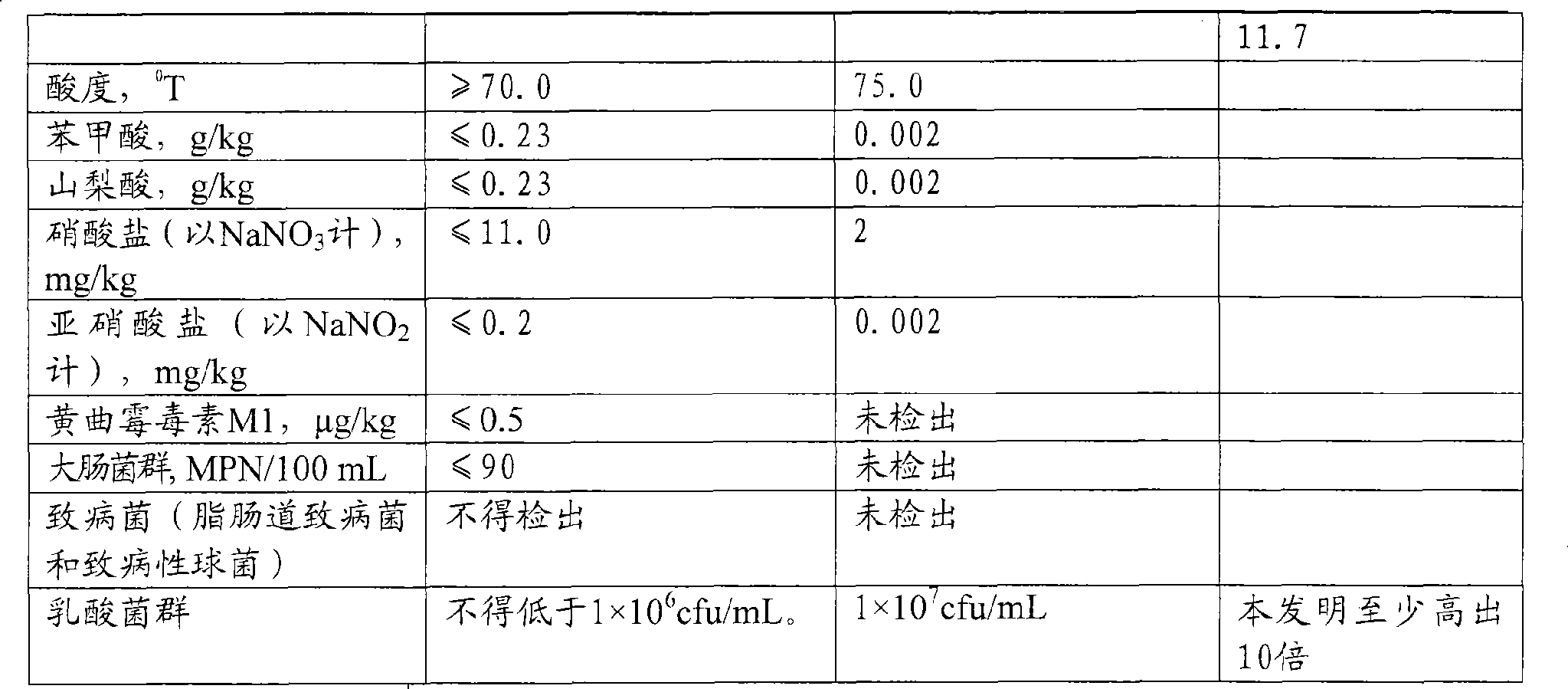

Examples

Embodiment 1

[0060] 1. Ingredients

[0061] 875kg of fresh milk; 1kg of grain powder (using black rice flour); 5kg of dairy additives; 0.2kg of lactic acid bacteria strains / functional probiotic strains; 48kg of flavoring agents; 3kg of stable thickeners.

[0062] The raw milk is checked and accepted according to the purchasing standard of GB6914 raw milk, and the milk is cleaned by a special milk cleaning machine, and the impurity reaches ≤4mg / kg, and is weighed according to the proportion;

[0063] Black rice flour is a commercially available commodity, and the production plant has undergone crushing and puffing processing, and the particle size is 100-200 mesh standard sieve;

[0064] The dairy additive uses 5kg of commercially available condensed milk;

[0065] The commercially available Lactobacillus delbrueckii subsp.bulgaricus, Streptococcus thermophilus, and Lactobalillus acidophilus approved by the Ministry of Health are used as strains;

Embodiment 2

[0077] 700kg of fresh milk; 30kg of cereal flour (oat flour); 44kg of dairy additives; 0.8kg of lactic acid bacteria strains / functional probiotic strains; 82kg of flavoring agents; 10kg of stable thickeners;

[0078] Oat flour is commercially available, and the production plant has undergone crushing and puffing processing, and the particle size is ≤80 standard sieve;

[0079] Dairy additives use 20kg of commercially available cream and 24kg of commercially available skimmed milk powder;

[0080] The commercially available Lactobacillus delbrueckii subsp.bulgaricus, Streptococcus thermophilus, and Lactobalillus acidophilus approved by the Ministry of Health are used as strains;

[0081] Sugar or non-sugar sweeteners (a mixture of sugar + glycyrrhizin) are used as flavoring agents; and natural and artificial flavors complying with GB2760 (in this case, peanut flavors are used);

[0082] The stable thickener uses a mixture of pectin + carboxymethyl cellulose.

[0083] Except f...

Embodiment 3

[0088] Fresh milk 787.5kg; grain powder (brown rice flour) 15kg; dairy additive 29kg; lactic acid bacteria strain / functional probiotic strain 0.5kg; flavoring agent 65kg; stable thickener 6.5kg;

[0089] Brown rice flour is commercially available, and the production plant has undergone crushing and puffing processing, and the particle size is ≤80 standard sieve;

[0090] Dairy additives use 5kg of commercially available cream and 24kg of commercially available skimmed milk powder;

[0091] The commercially available Lactobacillus delbrueckii subsp.bulgaricus, Streptococcus thermophilus, and Lactobalillus acidophilus approved by the Ministry of Health are used as strains;

[0092] Sugar or non-sugar sweeteners (a mixture of sugar + aspartame) are used as flavoring agents; and natural and artificial food flavors that comply with GB2760 (egg yolk flavors are used in this example);

[0093] The stable thickener uses a mixture of sodium alginate + carboxymethyl cellulose.

[0094...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com