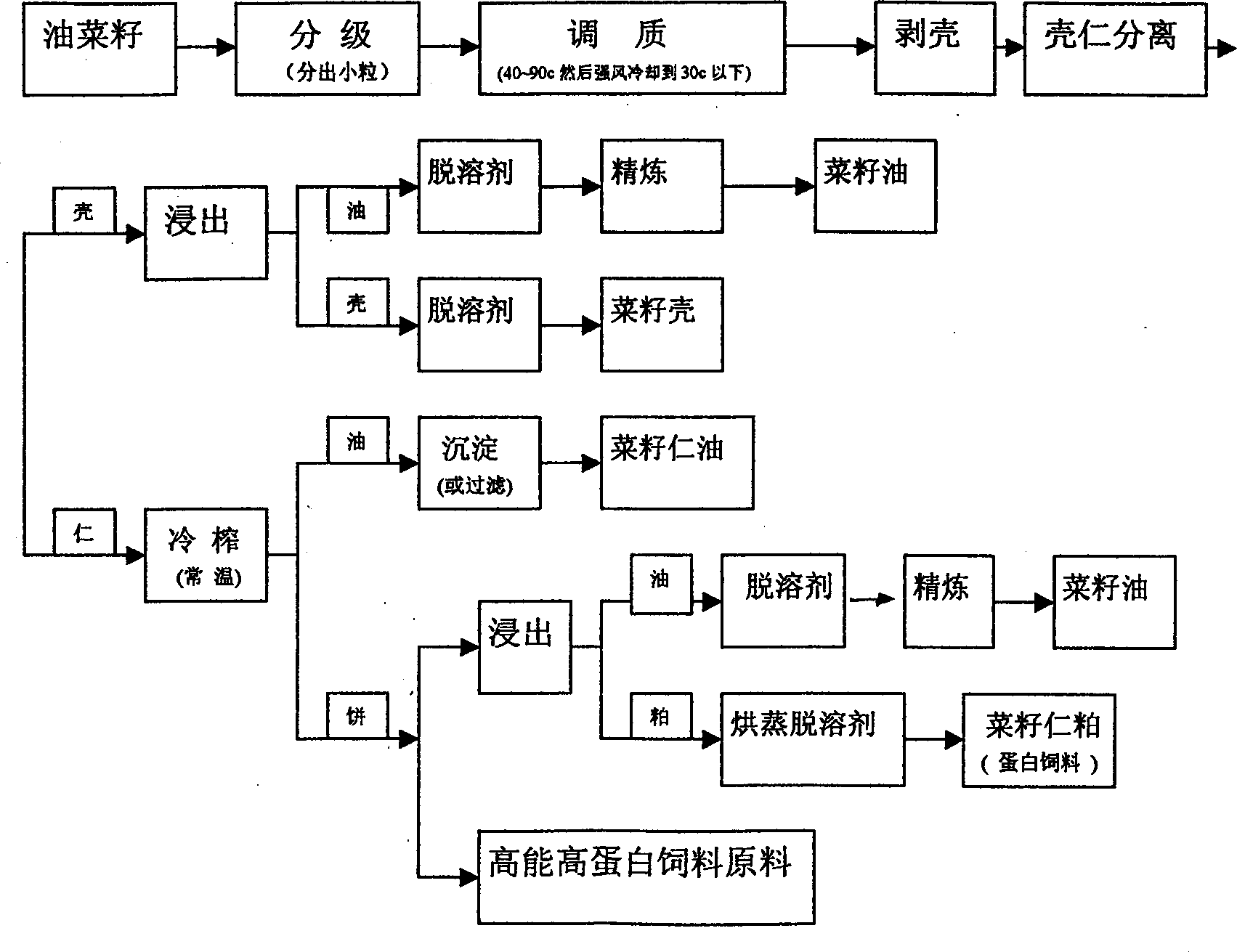

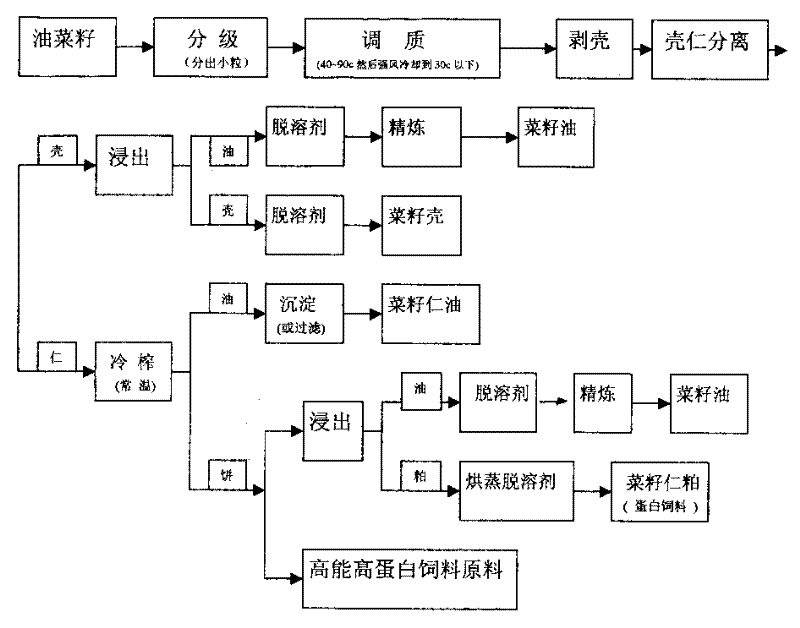

Process for separating repeseed kernel from shell and cold extracting oil

A rapeseed husk and process technology, which is applied in the production of fat oil/fat and fat production, can solve the problems of poor market adaptability, increased energy consumption of solvent recovery and high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] First, the rapeseed is classified with a grading sieve to separate the small grains. The graded rapeseed is sent to the conditioning machine. The front part of the conditioning machine is a horizontal steam tube bundle dryer, and the rear part is a blower. The rapeseed is first heated to 40-90°C, and then cooled by strong wind to below 30°C. After tempering, the rapeseed with brittle shell and tough kernel is sent to the toothed roller sheller for shelling, and then the shell and kernel are separated by vibrating screening machine and wind separator. The husk is directly leached to extract the contained oil, and the rapeseed husk is the secondary by-product of this process. The rapeseed kernels are sent to a continuous screw press and cold-pressed at room temperature to obtain all-natural rapeseed oil, which is not refined but has the appearance of refined oil, and retains all the nutrients and beneficial ingredients in natural oil. Continue to process the cake or di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com