Hinge type track chain railway shaped energy conversion device

An energy conversion device and hinge-type technology, which is applied in the fields of wind power, fire power energy conversion, and hydraulic power, can solve problems such as large resistance to useless work, increased friction between bearing bushes, and long construction cycle time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

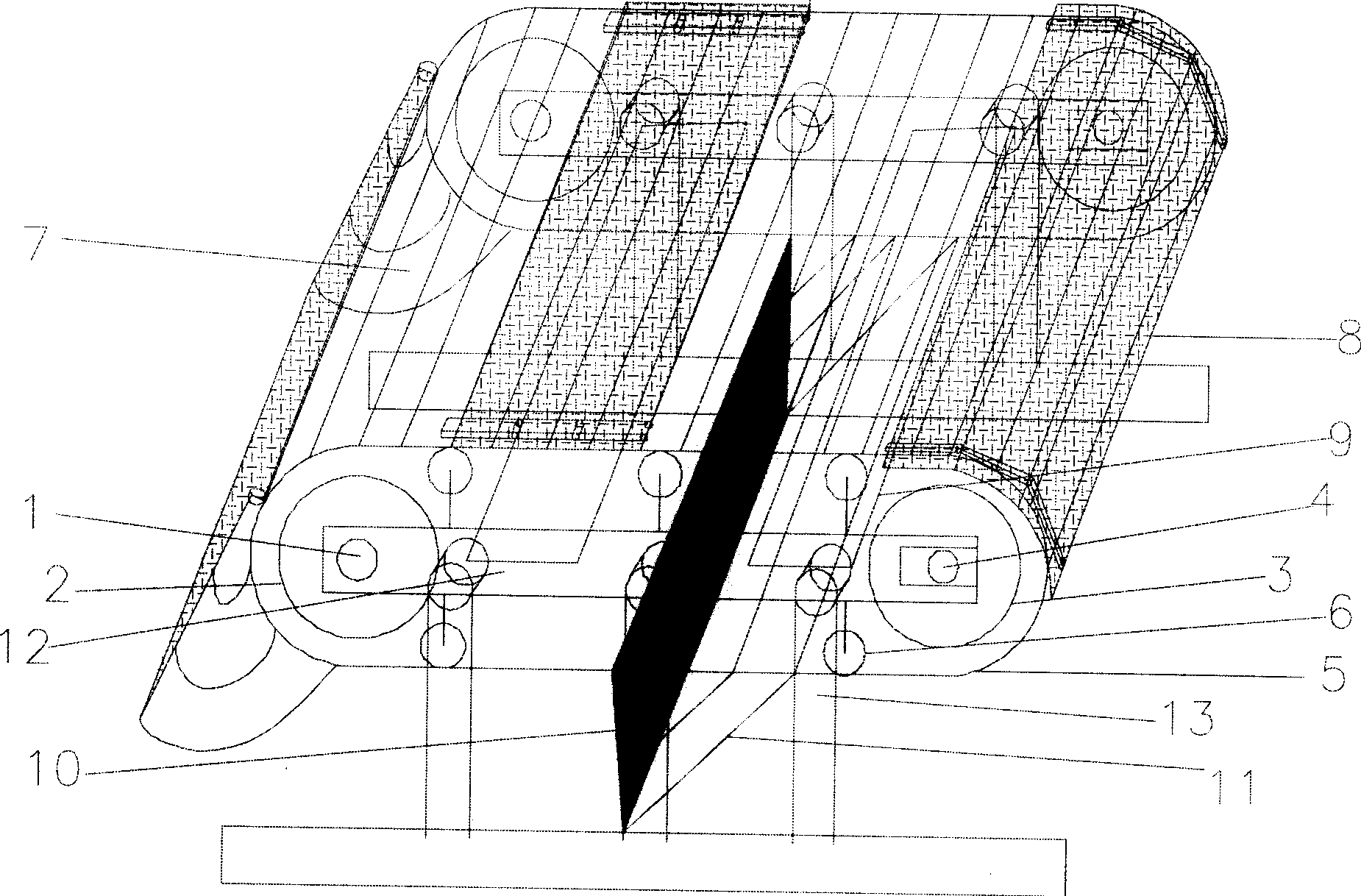

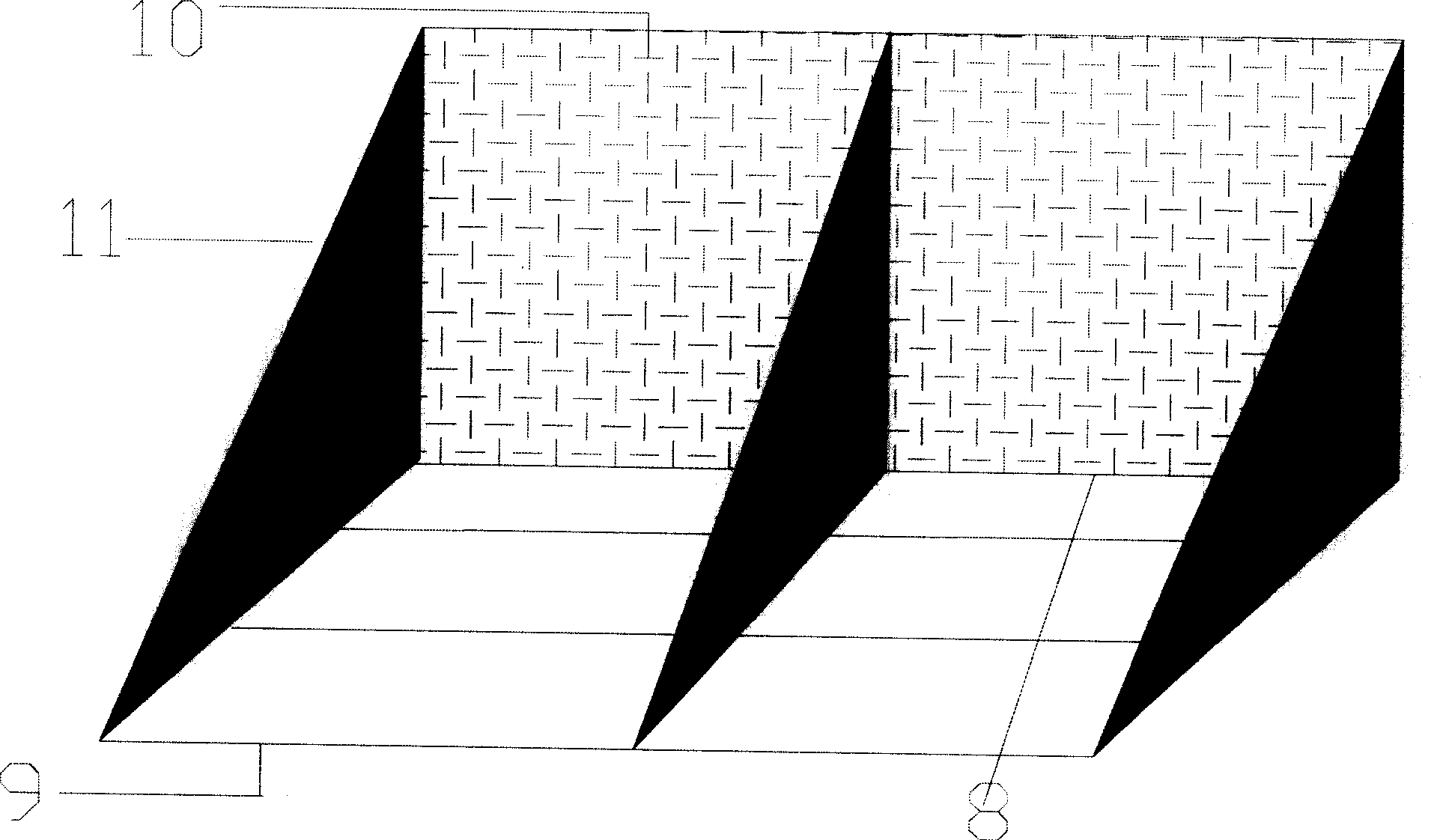

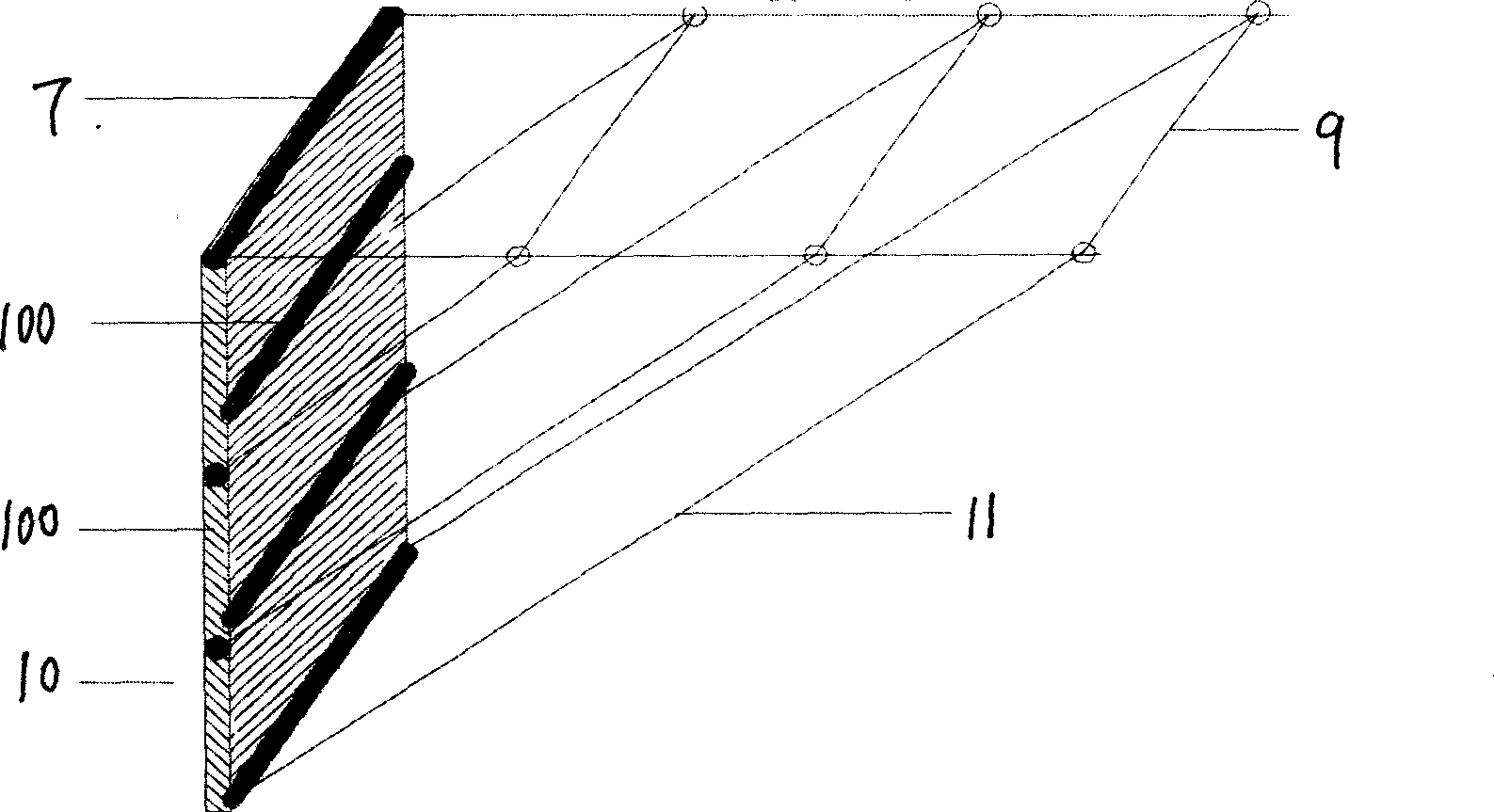

[0073] Embodiment 1: Hinge type crawler chain rail wheel-shaped energy conversion device reference figure 1 Installation: energy output shaft 1, and gear 2, driven wheel (or driven gear) 3, driven shaft 4, guide chain 5, supporting sprocket (or roller) 6, track shoes 7, hinged blades are fixed Plate (or bar) 8, stay cord (or chain) fixed plate (or bar) 9, several hinged blades 10, stay cord (or chain) 11, frame body (comprising beam) 12, support leg 13 constitutes.

Embodiment 2

[0074] Embodiment 2: The hinge-type crawler chain-rail wheel-shaped energy conversion device is provided with a fishtail-type direction indicator turntable for wind power conversion. Figure 4 ; The specific installation is to install the hinge type crawler chain rail wheel-shaped energy conversion device on the fishtail type direction indicator turntable. The fishtail direction indicator is composed of a plane frame 101, a bearing 102, a bearing support frame 103, and a fishtail wind direction plate 104; The wind direction board 104 can be installed on the plane frame, also can be installed on both sides of the tail end of the hinge type crawler chain rail wheel-shaped energy conversion device, one wind direction board 104 on each side. And when the blade faces upwards to obtain high-altitude wind power, the useless work resistance side is provided with a supporting plate pulley 201, a pulley bracket 202, and a sealing force plate 203; It is also possible to stop useless wor...

Embodiment 3

[0075] Embodiment 3: The hinge-type crawler chain-rail wheel-shaped energy conversion device is provided with a plate-type structure water channel 301 for hydraulic conversion. Figure 5 The specific installation is to install the hinge-type crawler track chain rail wheel-shaped energy conversion device on the plate-type water channel 301. ;Place it horizontally and install it in the river course to prevent dredging of sediment. Install vertically and obliquely for potential energy water diversion channel. (For example: 1 waterfall-type straight-down flowing water can be used for water diversion channel to convert the gravitational energy of its flowing water; 2 and for example, the water energy of the water outlet of a hydroelectric power station flows obliquely downward from a high place, and the hinge-leaf chain-rail wheel-shaped energy conversion device can be used It is connected with the plate structure waterway to face the water flowing down obliquely, and it is placed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com