Passenger car floor with sound insulation and decrease of noise functions

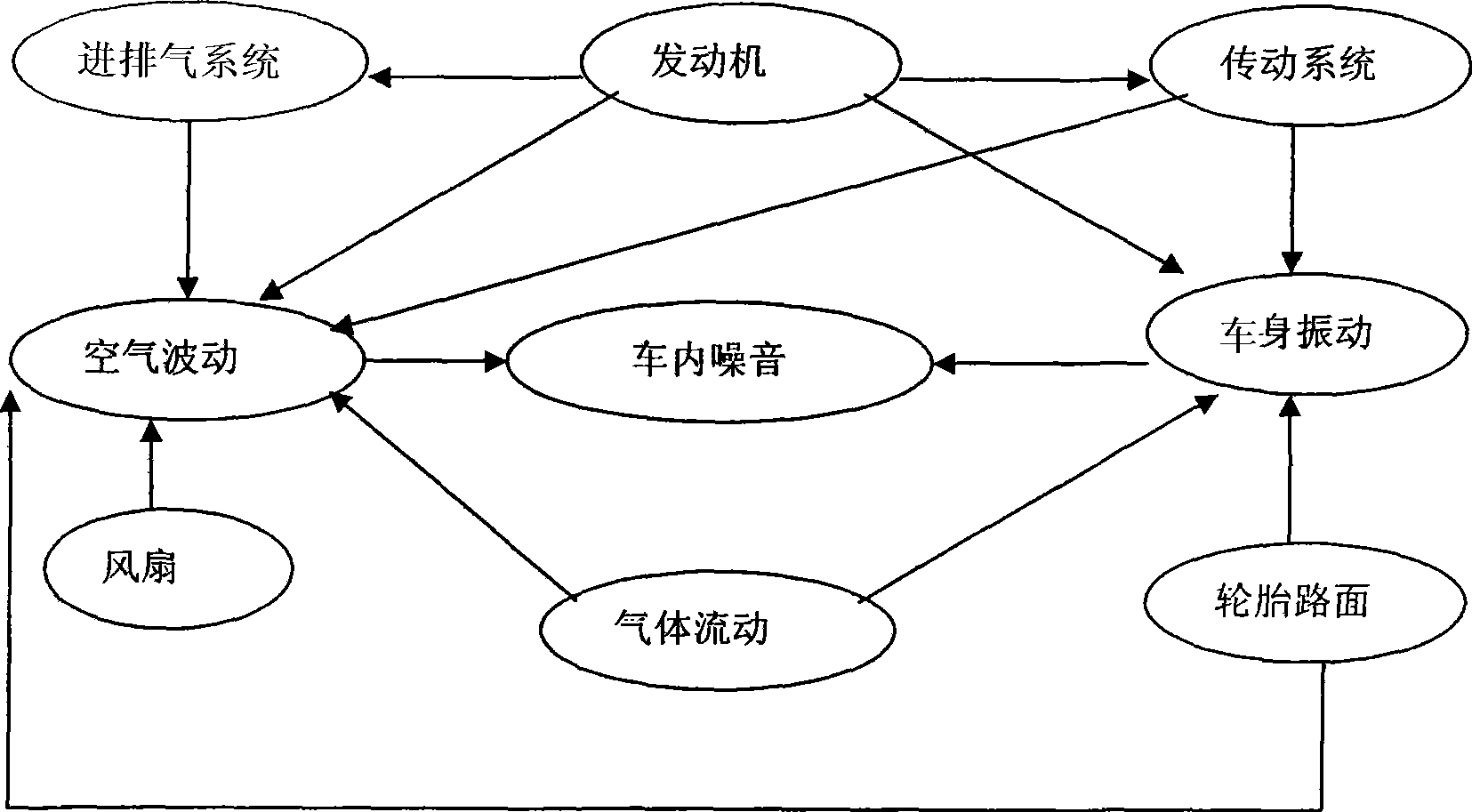

A passenger car floor and functional technology, applied to vehicle components, superstructure sub-assemblies, layered products, etc., can solve the problems of low noise limit standards, can not truly reflect the comfort requirements of passengers, and achieve the goal of reducing wind noise Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Below in conjunction with accompanying drawing, the present invention will be further described:

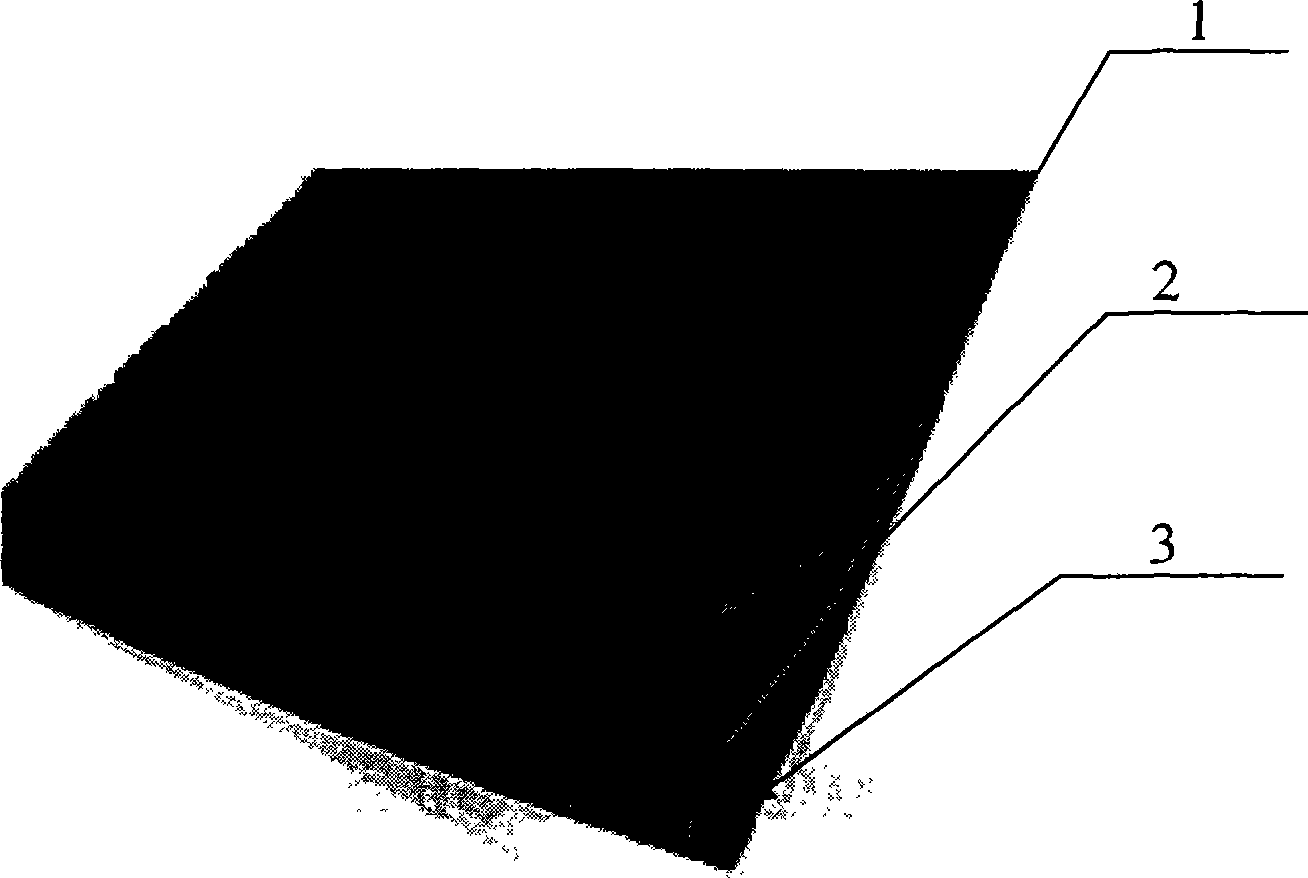

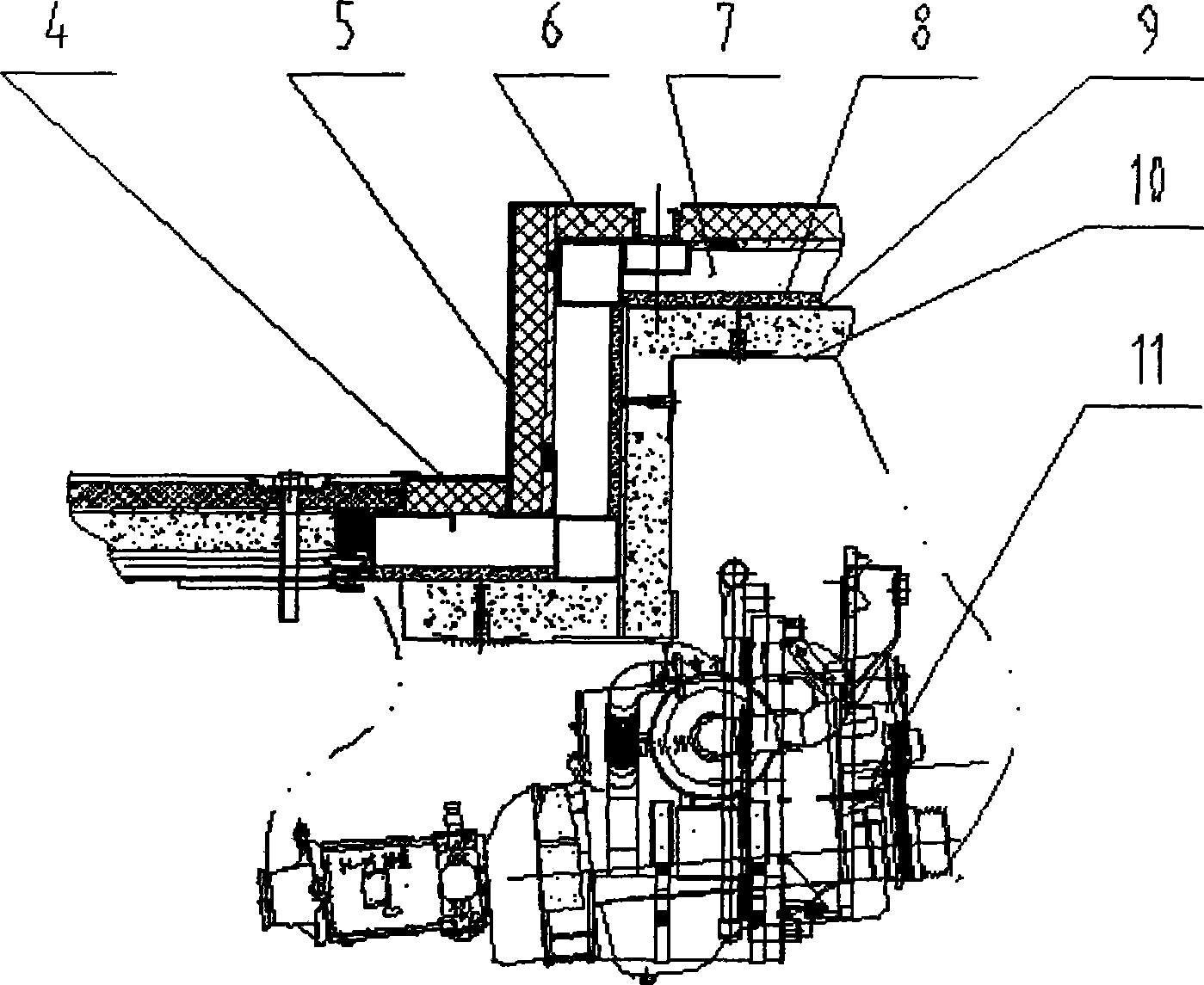

[0035] A passenger car floor with sound insulation and noise reduction functions, which is arranged at the rear of the passenger car, and the rear engine 11 of the passenger car is located below. , plywood layer 6, cavity 7, multi-layer composite sound-absorbing cotton layer 8, steel plate layer 9, self-skinning rubber sponge layer 10, such as image 3 shown. The multi-layer composite sound-absorbing cotton layer 8 includes three layers, which are sequentially from top to bottom: porous sponge sound-absorbing layer 1, high-density rubber-plastic sponge sound-insulating layer 2, and self-adhesive damping sound-insulating layer 3, such as figure 2 shown. The floor is provided with an inspection port for the rear engine, and an inspection cover is provided on the inspection port. The inspection cover includes the following four layers, which are in order from top to bottom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com