Laser cutting method

A laser cutting and cutting direction technology, applied in laser welding equipment, metal processing equipment, welding equipment, etc., can solve problems such as carbonization and affecting cutting quality, and achieve the effects of reducing carbonization, improving cutting quality, and removing corner points

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below through specific embodiments and in conjunction with the accompanying drawings.

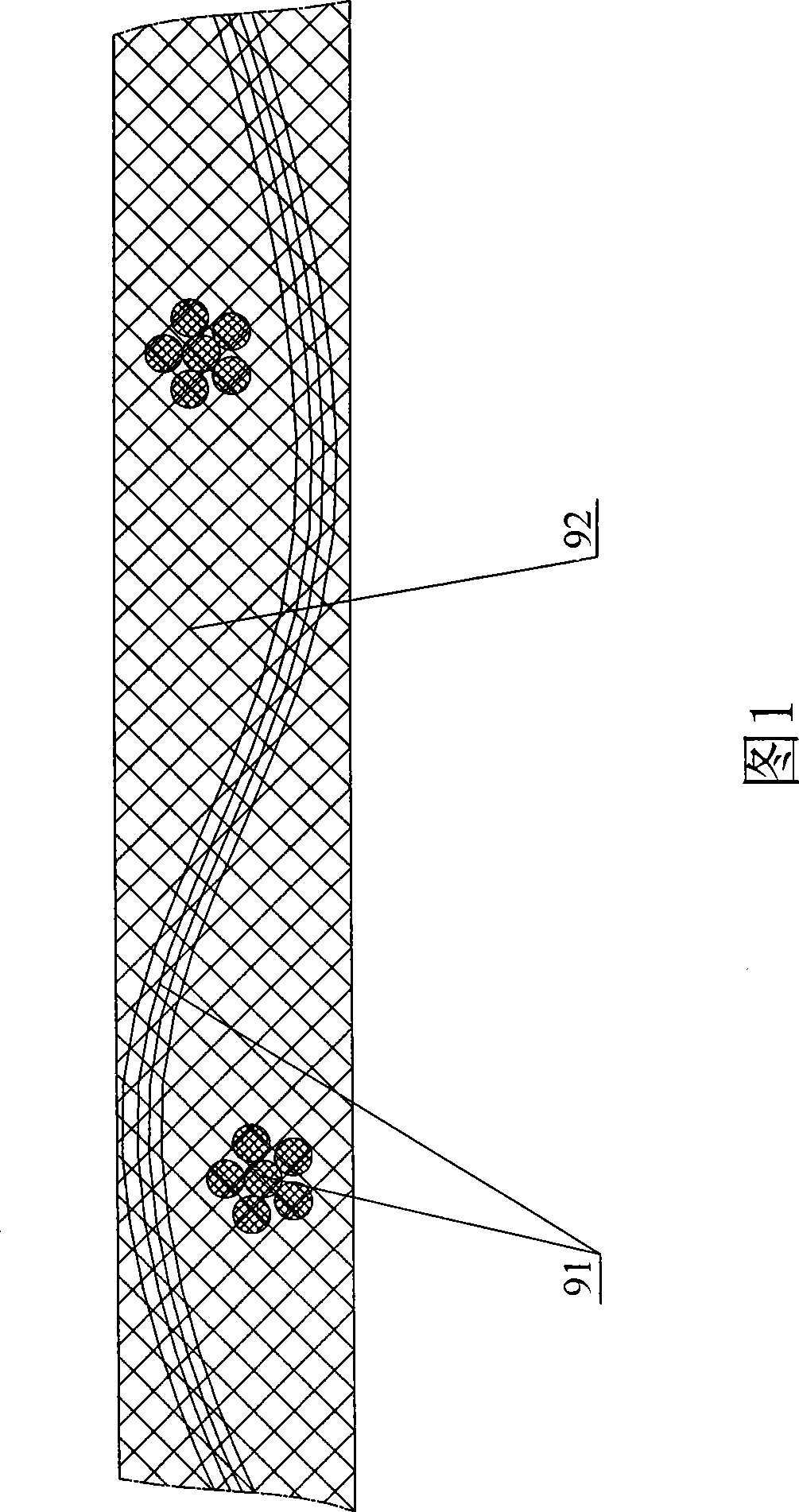

[0019] The laser cutting method of the present invention is mainly used for cutting non-metallic materials sensitive to lasers such as P / P boards. This is because non-metallic materials have high requirements on cutting quality, otherwise their quality will be affected. A new laser cutting method is designed for metal material cutting, which not only meets the cutting requirements, but also has high cutting quality.

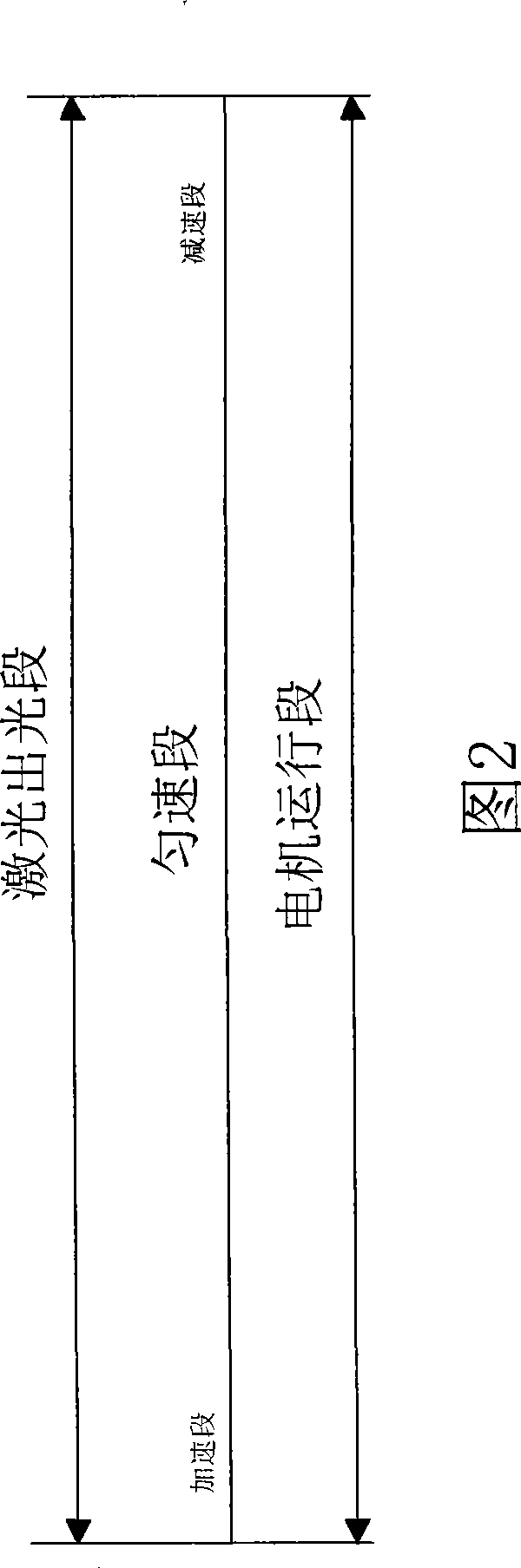

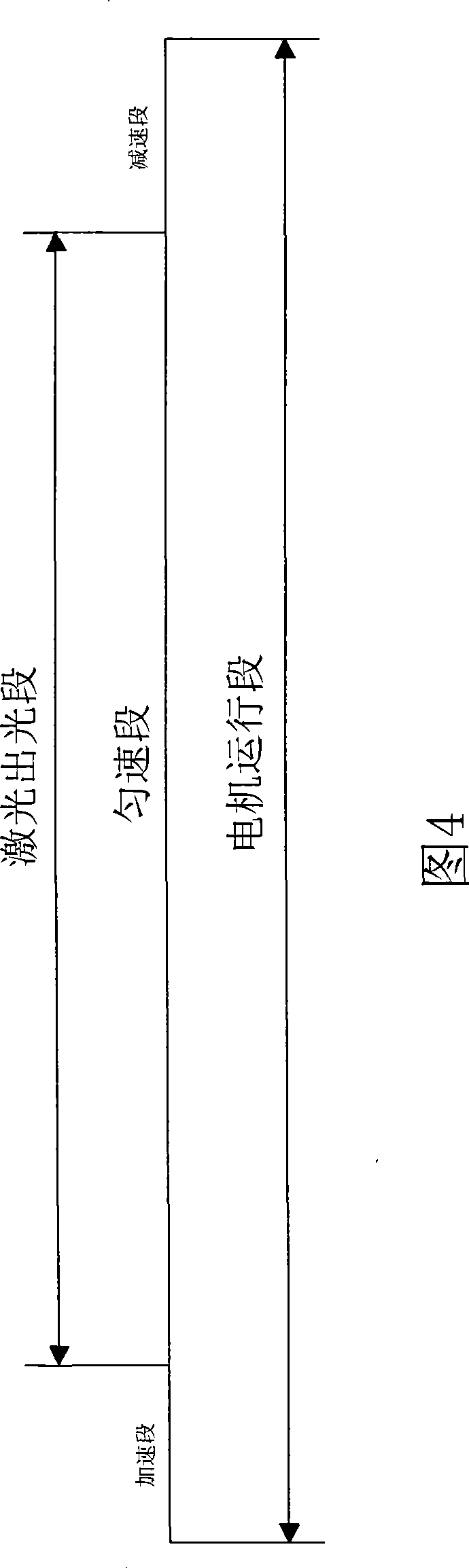

[0020] Sometimes it is only necessary to cut the P / P board in a simple straight line, as shown in Figure 4, which is a schematic diagram of cutting a single straight line. When cutting, set the power and speed of laser cutting in advance, and then start the motor. The whole cutting steps are as follows:

[0021] Step 1: Place the motor on the left side of the desired cutting line, start the motor, and the motor d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com