Puncher

A piercing machine and open hole technology, which is applied in the field of piercing machines, can solve the problems of cost increase and achieve the effect of long life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

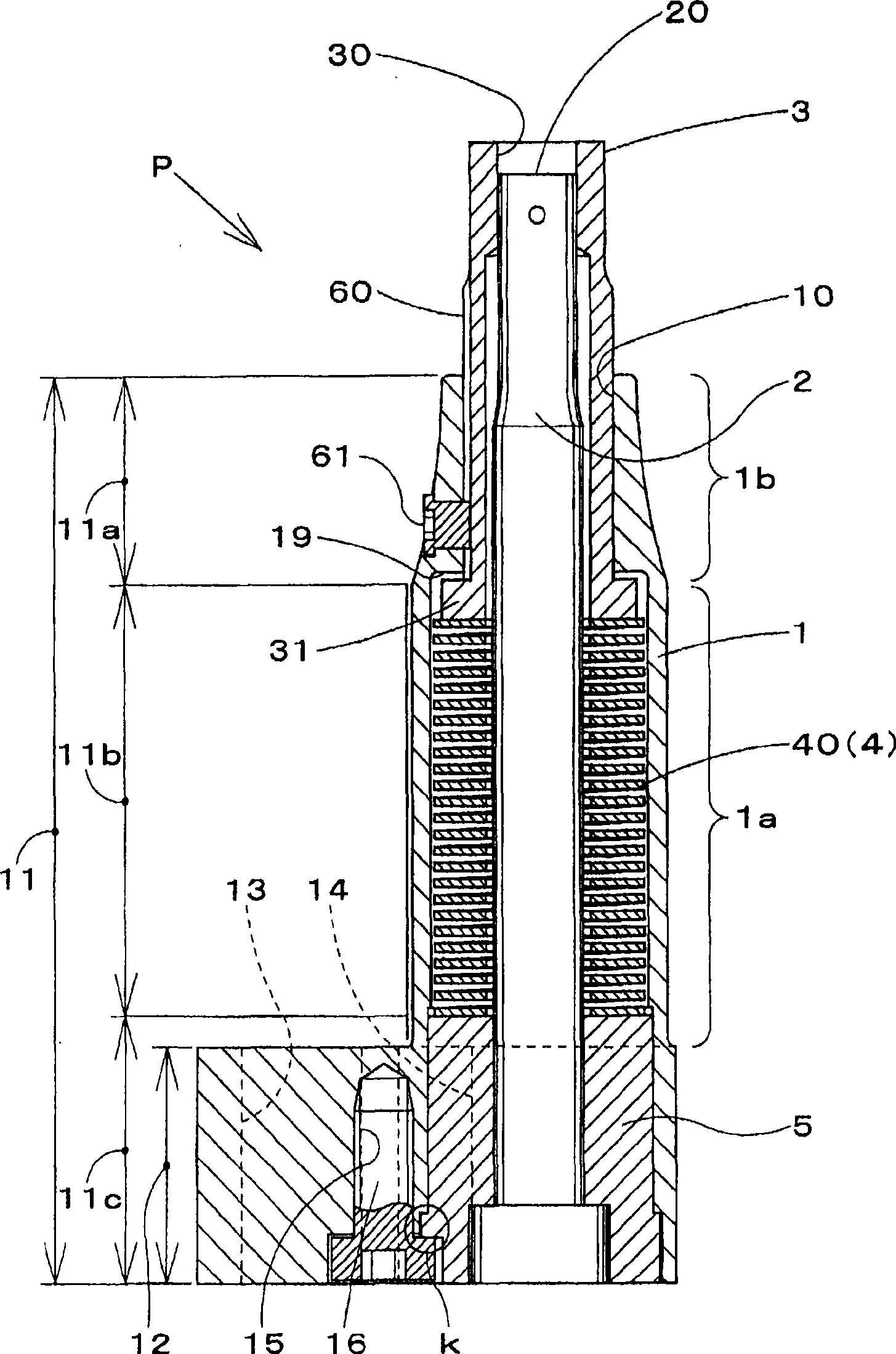

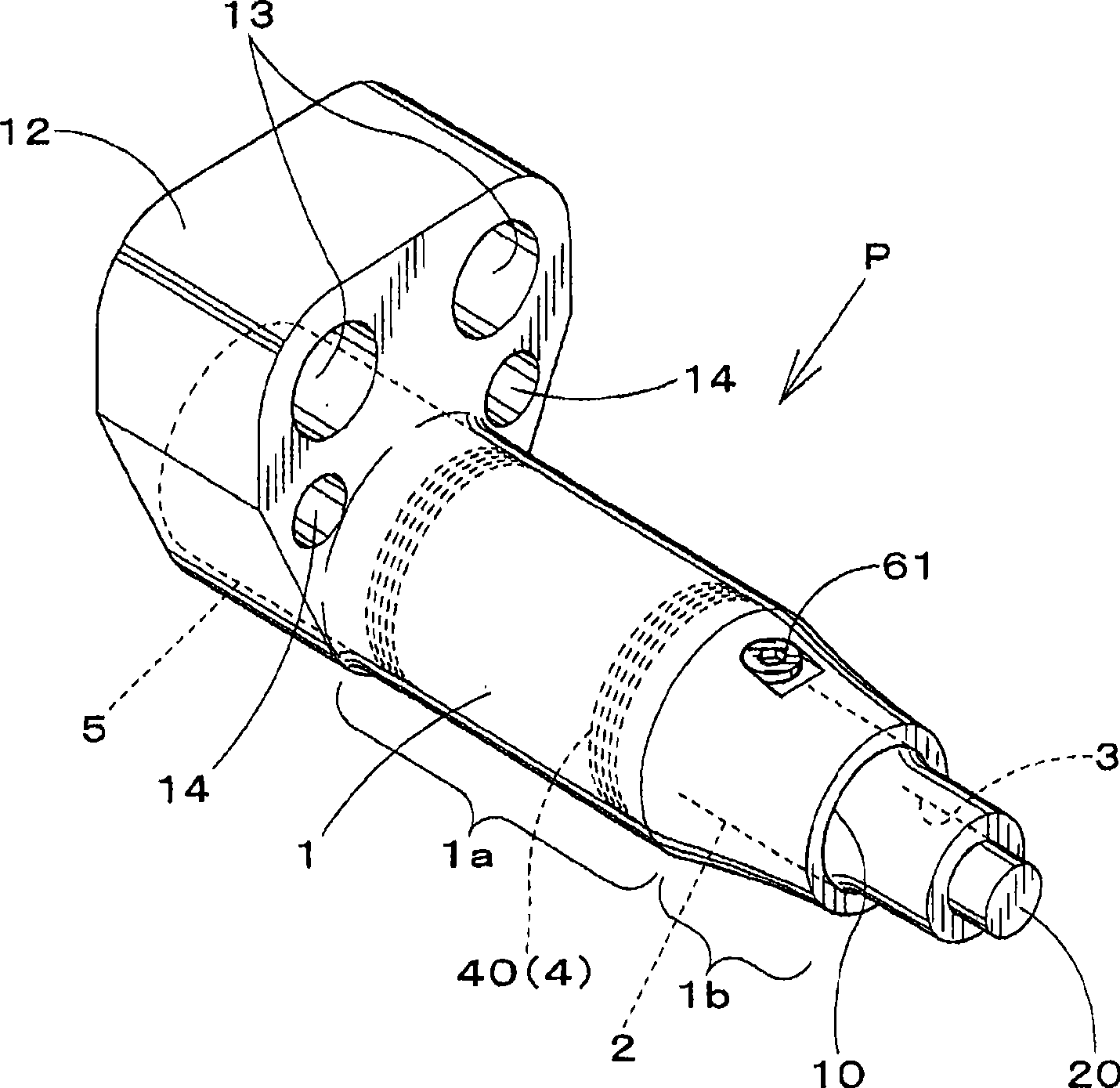

[0041] Next, examples will be described in detail as the best mode for carrying out the punching machine of the present invention.

[0042] The piercing machine of the embodiment 1 of the application of the present invention is as Figure 1-6 shown. The piercer P as figure 1 or figure 2 As shown, in the state where the tip end surface 20 of the punch 2 has the one end open hole 10 protruding from the above-mentioned one end open hole 10 of the cylindrical cover, the punch 2 is held immovably by the punch. The device 5 is loosely inserted and arranged in the above-mentioned cover 1, and the cylindrical punching template 3 is set in a state of preventing the separation between the above-mentioned cover 1 and the punching punch 2, and the punching template is made by using the force applying device 4. 3 protrudes more from the open hole 10 than the piercing punch 2. And, utilizing the pressing force to the punching template 3 that overcomes the force of the above-mentioned ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com