Continuous current micro-reactor and preparation method and use thereof

A microreactor and reaction technology, applied in chemical instruments and methods, chemical/physical/physical chemical processes, chemical/physical processes, etc., can solve the problems of slow synthesis speed, lack of economy and environmental protection, low synthesis efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

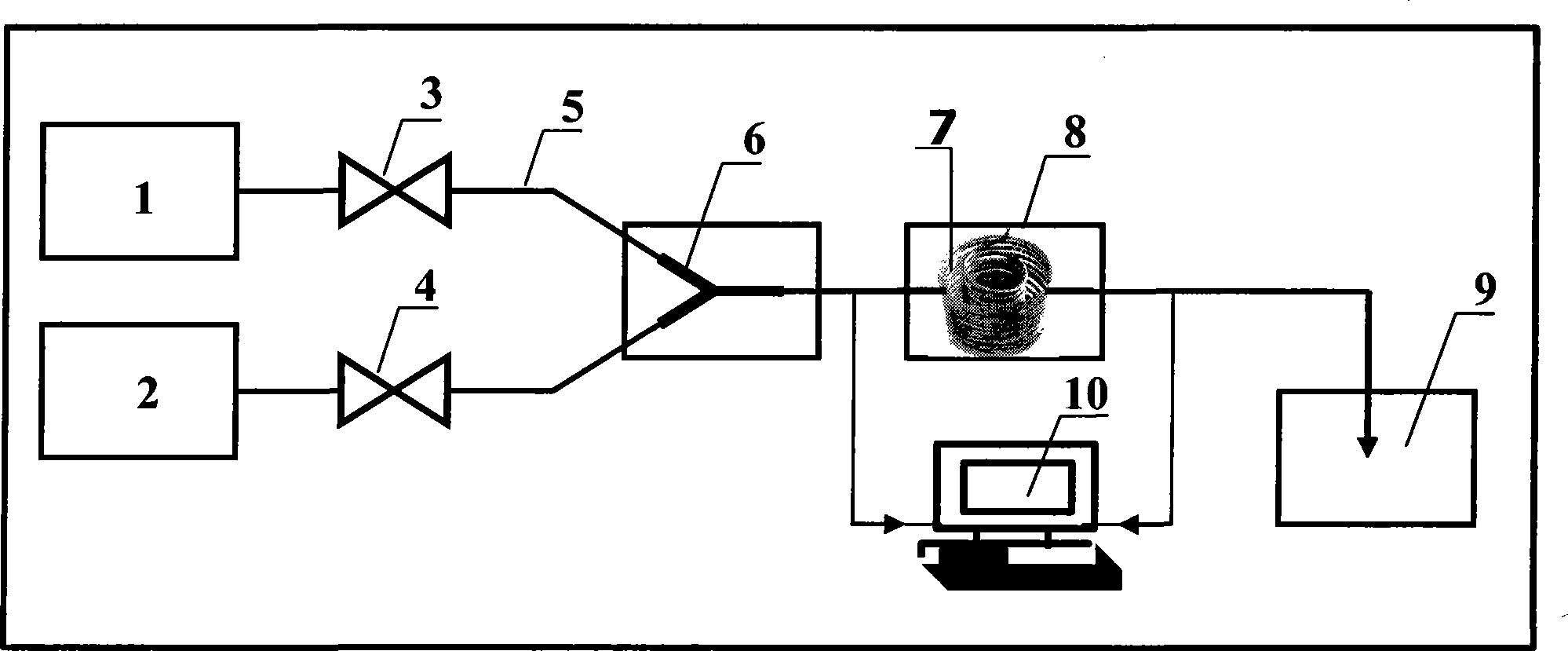

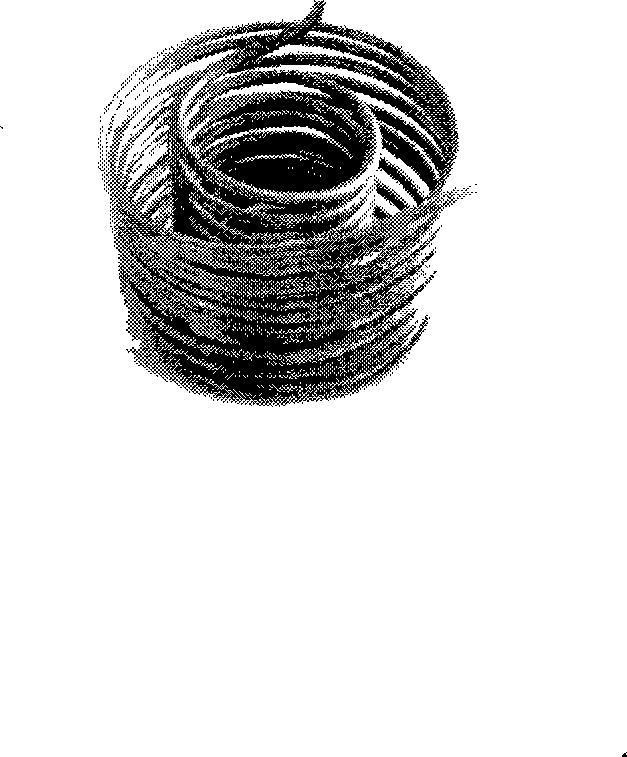

[0025] Example 1: Fabrication of serpentine double-helix capillary reaction tube

[0026] Use a glass capillary with an inner diameter of 100 μm-1000 μm and an outer diameter of 250 μm-1500 μm (or a capillary made of different materials such as quartz, stainless steel, or polytetrafluoroethylene), on a self-made capillary winding instrument, etc. When the temperature rises to a certain value, spiral winding is carried out from bottom to top, the number of spirals is any number between 10-100 turns, and the inner diameter of each turn is the same, which is between 1cm-10cm, and then spiral winding is carried out from top to bottom The number of spirals is still 10-100 circles, and the inner diameter of each circle is the same, which is between 1.5cm-20cm. The same capillary is used in the whole winding process. After the winding is completed, it is slowly cooled in the air to form a serpentine double-helix capillary reaction tube. The reaction tube has an inlet and an outlet a...

Embodiment 2

[0027] Embodiment two: the making of Y type or T type micro-mixer

[0028] Use a glass capillary with an inner diameter of 100 μm-1000 μm and an outer diameter of 250 μm-1500 μm, and sinter it into a Y-shaped or T-shaped tube on an alcohol blowtorch to make it a Y-shaped or T-shaped tee tube. The length of each channel Both are between 5mm-25mm. The miniature tee is a Y-type or T-type micro-mixer.

Embodiment 3

[0029] Embodiment 3: optical detector tracking reaction process

[0030] A three-way valve is installed at the inlet end and the outlet end of the serpentine double-helix capillary reaction tube, and a hose is respectively connected to the three-way valve, and the hose is respectively connected with the sample pool in the optical detector. After the reaction is completed, the inlet and outlet samples of the serpentine double-helix capillary reaction tube are collected for online detection, and the degree of the reaction is determined by comparing the changes in the spectral data before and after the reaction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com