Socket for cathode tube

A technology for cathode tubes and tubes, which is applied in the direction of discharge tubes, coupling devices, lighting and heating equipment, etc., and can solve problems such as unstable electrical connections, tilted clamping angles, and broken cold cathode tubes 1

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

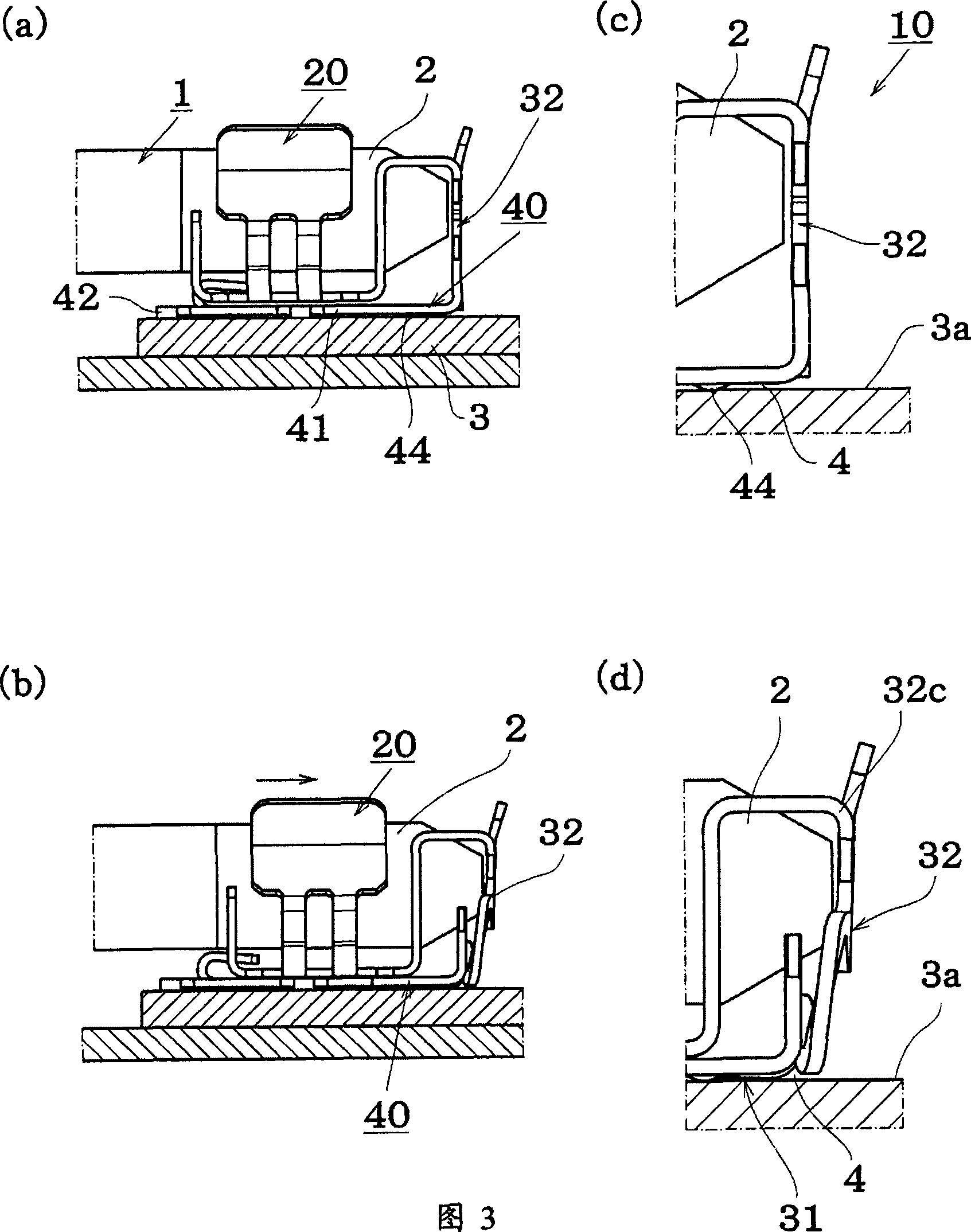

[0040] Embodiments of the socket for cathode tubes according to the present invention will be described below with reference to the drawings.

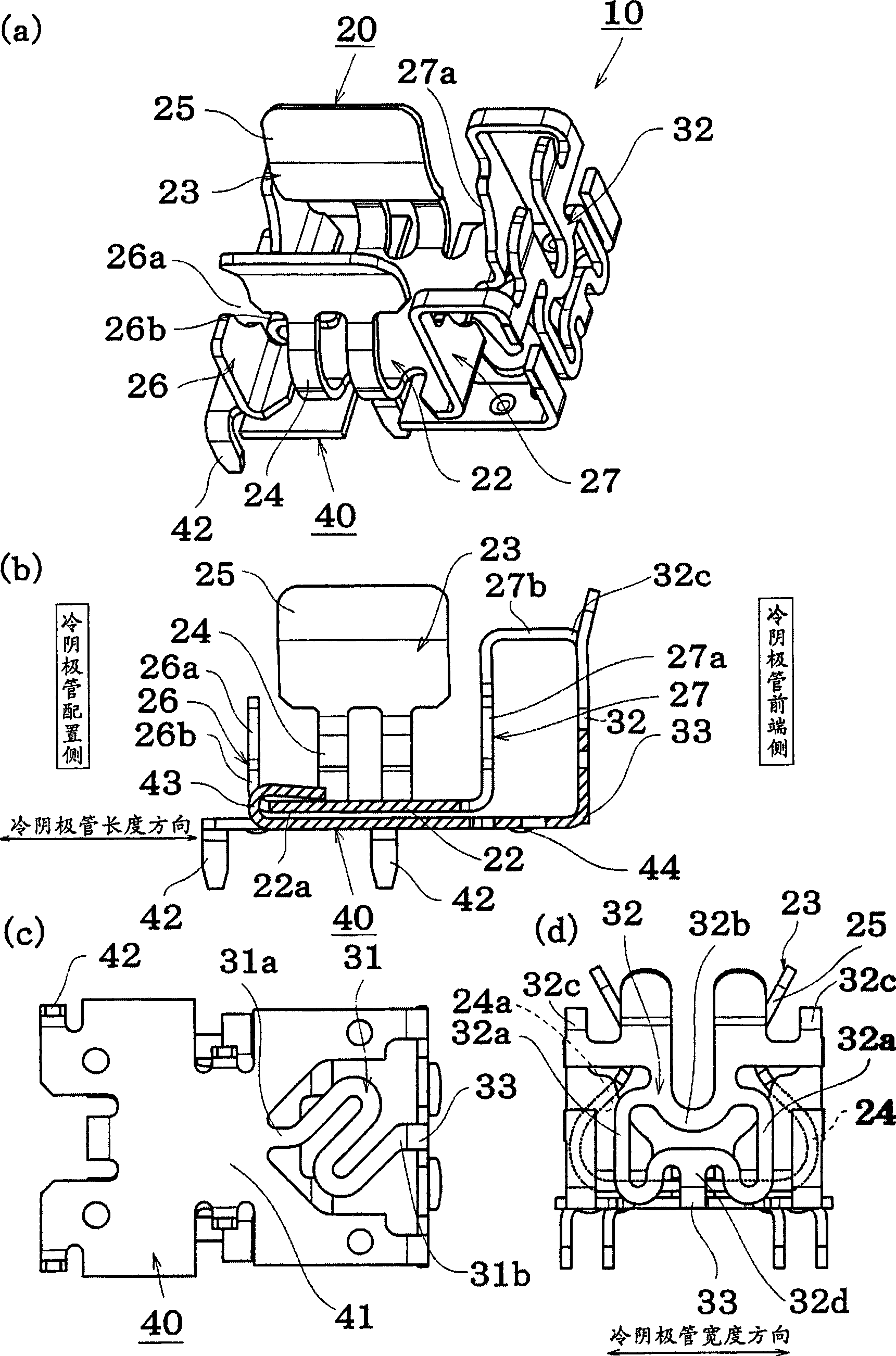

[0041] figure 1 , figure 2 It is an explanatory diagram of the socket, figure 1 (a) represents a perspective view, figure 1 (b) represents a longitudinal sectional view cut along the length direction of the installed cold cathode tube, figure 1 (c) represents a bottom view, figure 1 (d) shows a view seen from the side of the front end of the cold cathode tube.

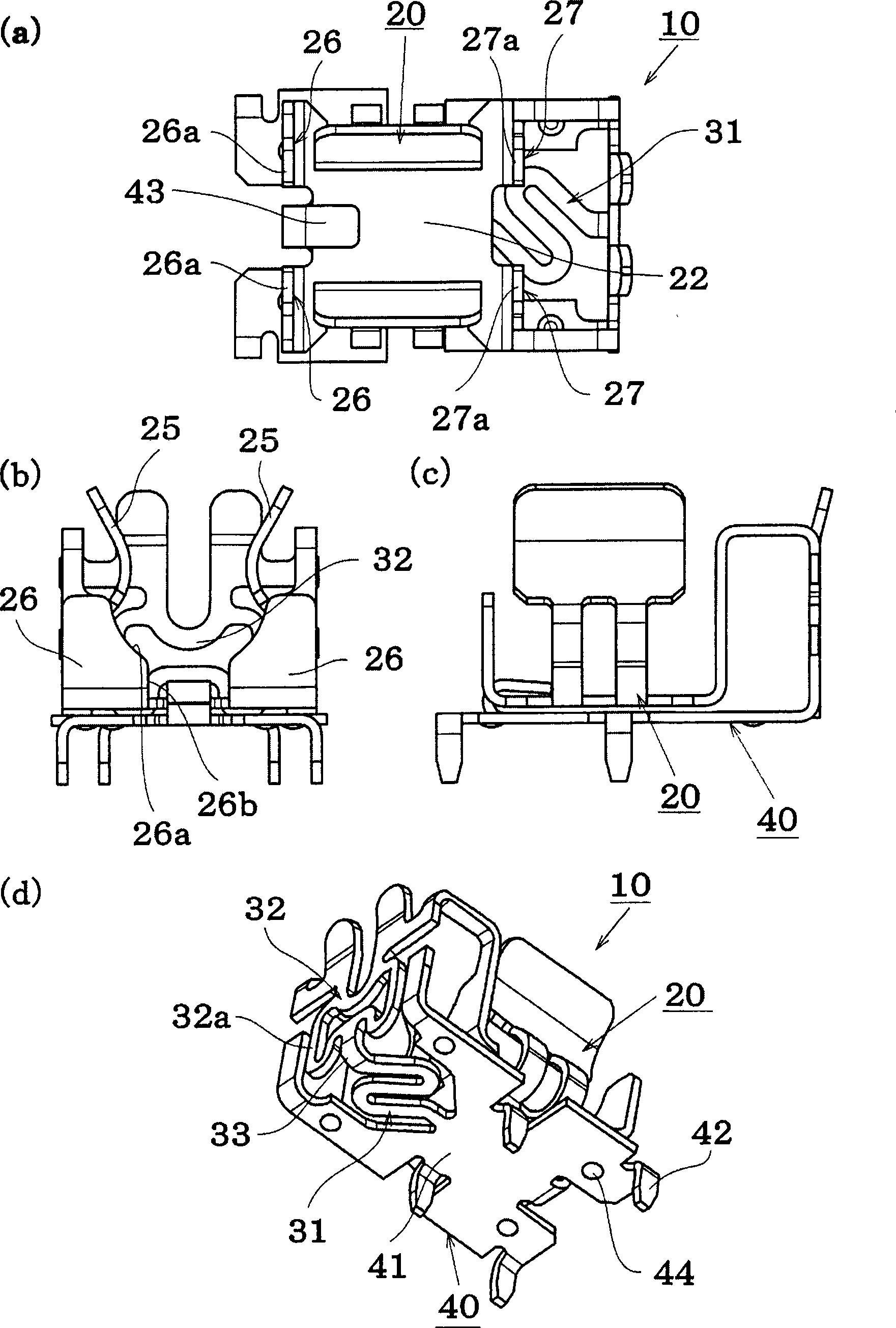

[0042] figure 2 (a) represents a top view, figure 2 (b) shows a view seen from the cold cathode tube arrangement side, figure 2 (c) shows a view seen from the side in the longitudinal direction of the cold-cathode tube, figure 2 (d) shows a perspective view seen from the bottom side.

[0043] The socket 10 has a clamping part 20 for clamping and connecting the terminal part of the cold cathode tube and a circuit board mounting part 40 installed on the circuit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com