Quench-detection circuit of high-temperature superconducting magnet

A high-temperature superconducting and detection circuit technology, which is applied in the direction of measuring electricity, measuring electrical variables, and measuring devices, can solve the problems of permanent damage to high-temperature superconducting magnets, damage to high-temperature superconducting magnets, and slow quench propagation speed, etc., to achieve The effect of fast speed, improved accuracy, and reduced influence of interference signals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings.

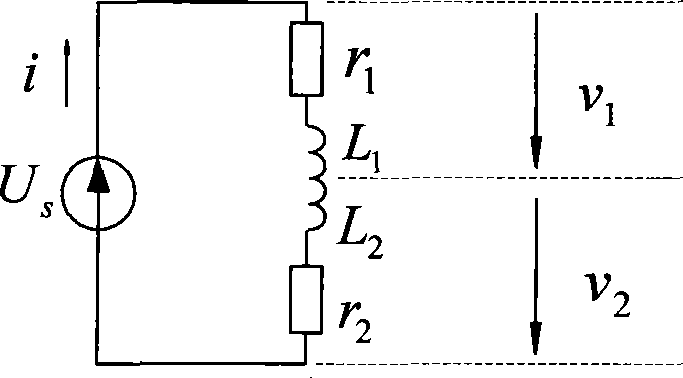

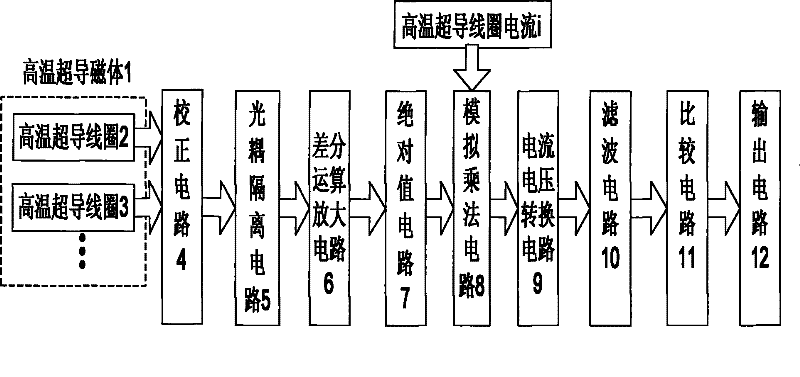

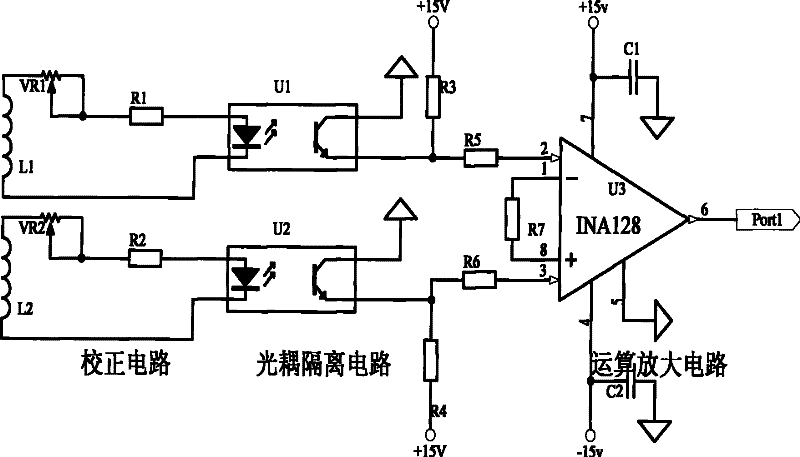

[0020] figure 2 It shows a schematic diagram of quench detection for high-temperature superconducting magnets, which consists of the following parts: high-temperature superconducting magnet 1, high-temperature superconducting coil 2, high-temperature superconducting coil 3, correction circuit 4, optocoupler isolation circuit 5, differential calculation Amplifying circuit 6, absolute value circuit 7, analog multiplication circuit 8, current-voltage conversion circuit 9, filter circuit 10, comparison circuit 11 and output circuit 12, wherein high temperature superconducting magnet 1 is composed of high temperature superconducting coil 2, high temperature superconducting coil 3 high temperature superconducting coils connected in series. Taking the high-temperature superconducting coil 2 and the high-temperature superconducting coil 3 as an example, the specific implemen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com