Method for measuring vertical displacement by hydraulic pressure and temperature and device thereof

A vertical displacement and temperature measurement technology, applied in the direction of measuring devices, fluid devices, elastic testing, etc., can solve problems such as abnormal use, high requirements for operation and adjustment, strong light interference, etc., to improve measurement accuracy , high degree of automation and high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

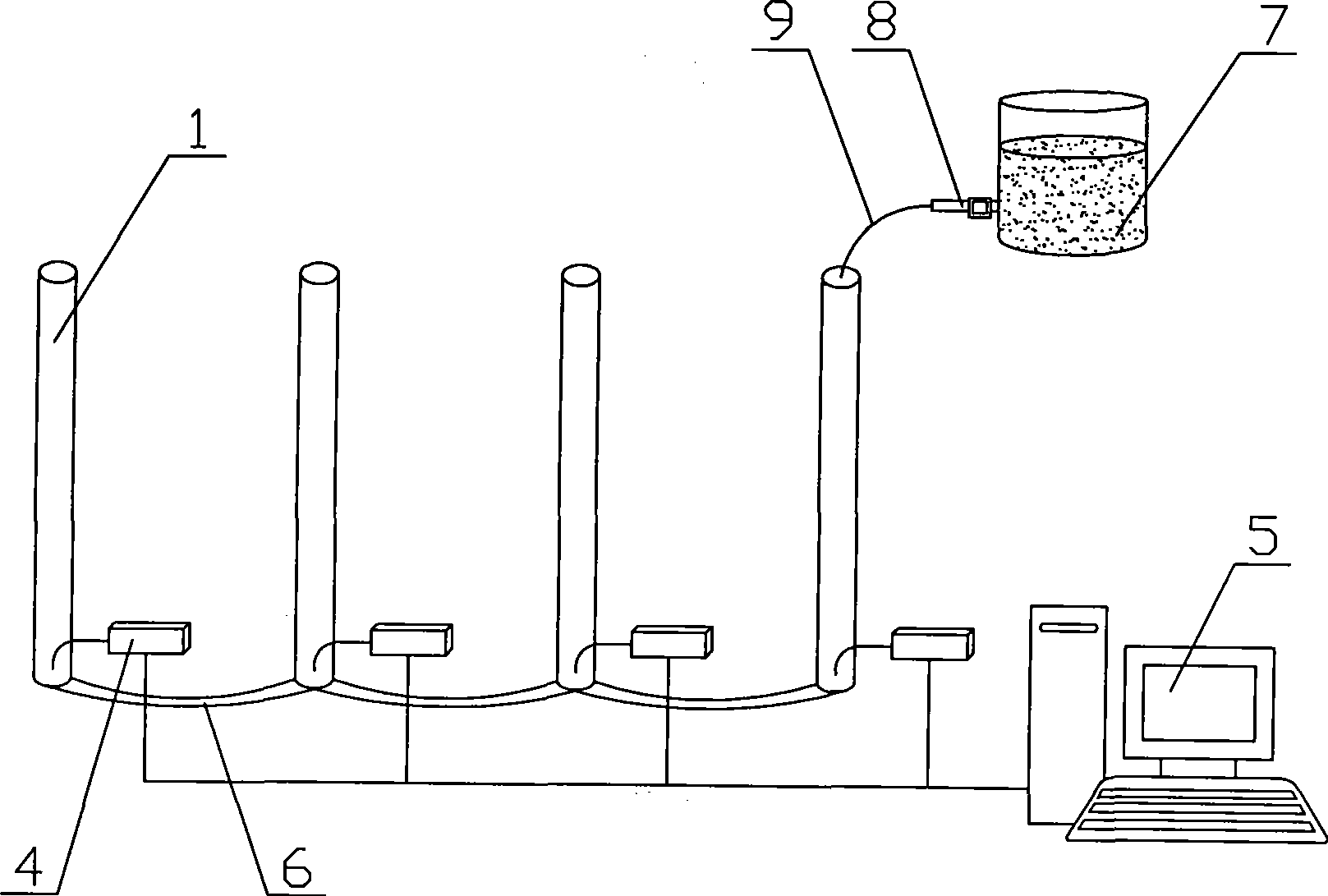

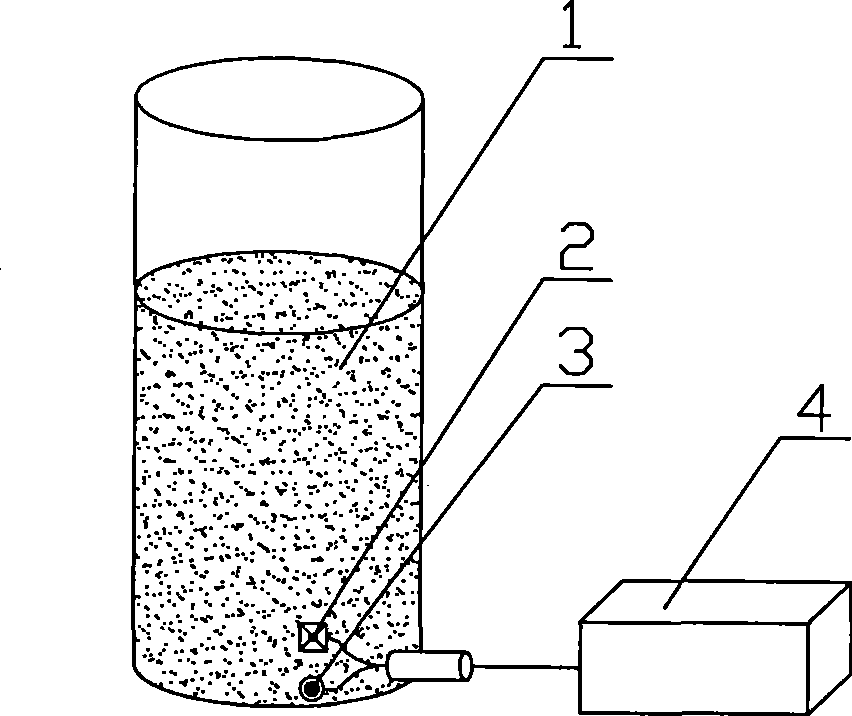

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

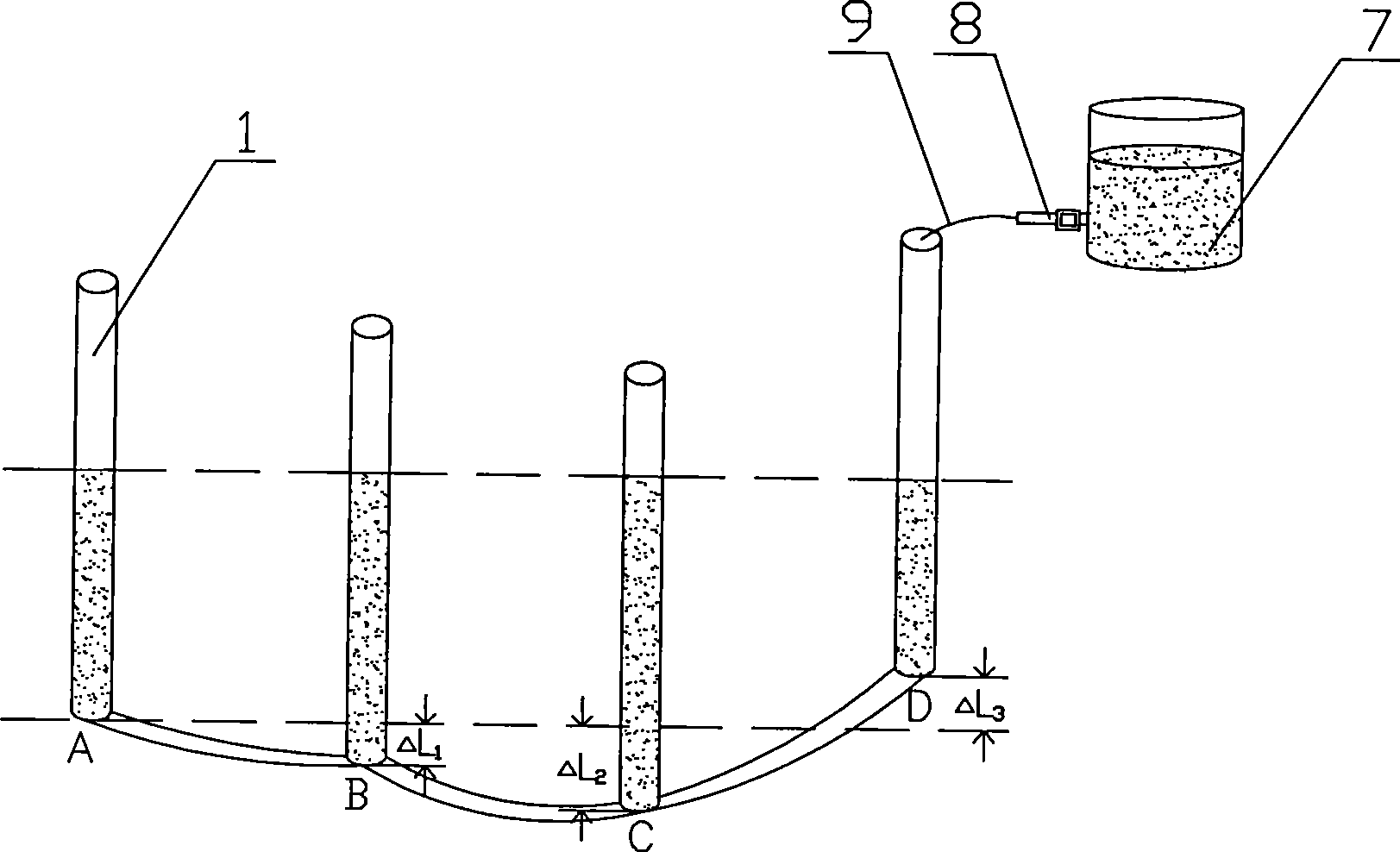

[0024] A method for measuring vertical displacement using hydraulic pressure and temperature, is to install pressure sensors and temperature sensors at the inner bottom of a plurality of identical liquid holding pipes, and the pressure sensors and temperature sensors communicate with the computer system through a circuit (with a control processor) connected; the bottoms of the plurality of liquid holding pipes are connected through flexible pipes, one of the liquid holding pipes is set vertically at the reference point, and the remaining liquid holding pipes are respectively vertically set at each point to be measured;

[0025] According to the change of vertical displacement of each point to be measured, the liquid depth of the liquid pipe increases or decreases accordingly;

[0026] The current pressure F measured by each pressure sensor 0 ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com