Drainage device for coal bed gas well electric submersible centrifugal pump

A technology for coalbed methane wells and centrifugal pumps, which is applied to pump devices, components of pumping devices for elastic fluids, pumps, etc., can solve problems such as high energy consumption, low pumping unit movement efficiency, and lack of energy conservation. The head and efficiency are stable, avoiding cavitation damage to the blades, and improving the output of a single well

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

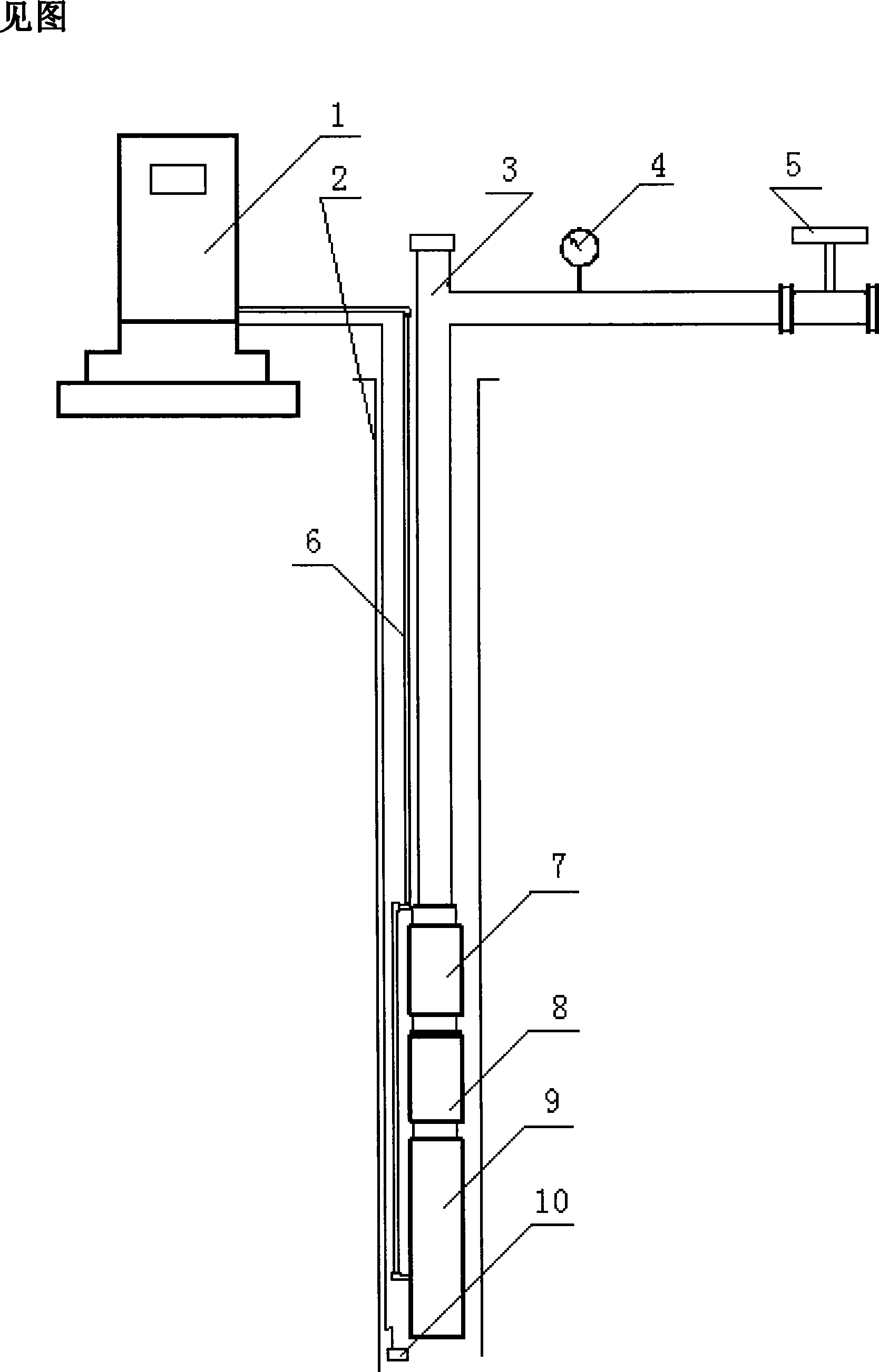

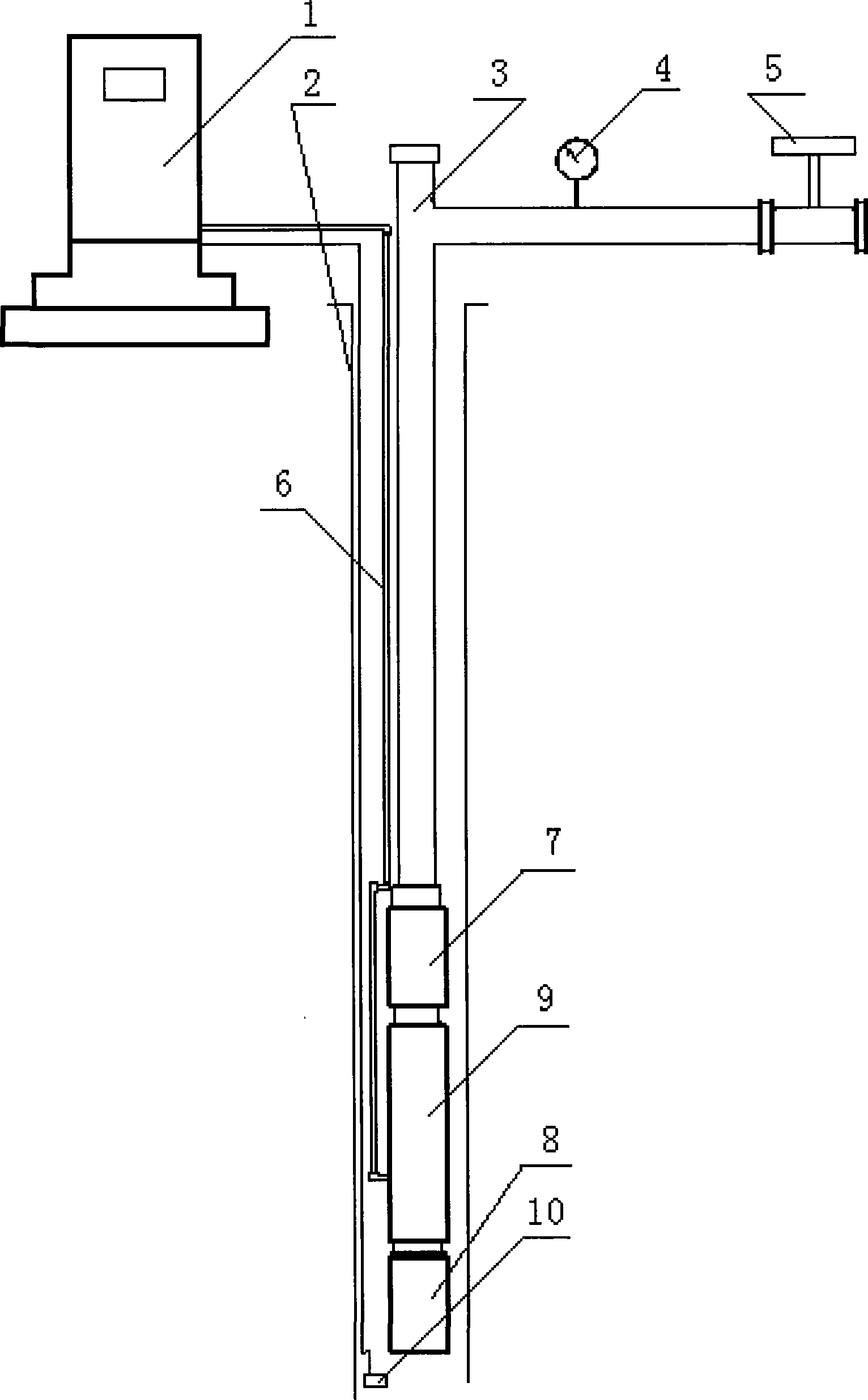

[0013] Embodiment 1: see figure 1 . The electric submersible centrifugal pump drainage device for coalbed gas wells of the present invention uses the electric submersible centrifugal pump 7 which is a large-lift multistage electric submersible centrifugal pump. The cable 6 connects the electric submersible centrifugal pump 7 and the controller 1 to provide power for the electric submersible centrifugal pump 7 . The electric submersible centrifugal pump 7 can reach 800 meters lift through the control system, 0.1m 3 / day traffic. The main components in the controller 1 include a central control unit (such as a PLC), a frequency converter, a man-machine interface, and the like. The controller 1 can realize the closed-loop control of the pump and the control of the flow regulator 5 of the water outlet. On the ground, the controller 1 has wires connected to the downhole drainage pump motor 9 . A horizontal liquid outlet pipeline is connected to the upper end of the oil pipe 3 ...

Embodiment 2

[0015] Embodiment 2: basically the same as Embodiment 1, the difference is:

[0016] The inlet end of the electric submersible centrifugal pump 7 is connected to the drainage pump motor 9 , and the lower end of the drainage pump motor 9 is connected to the gas-liquid separator 8 . There is a sleeve on the periphery of the drainage pump motor 9, and there is an annular channel between the inner wall of the sleeve and the casing of the drainage pump motor 9. The liquid separated by the gas-liquid separator 8 enters the inlet of the electric submersible centrifugal pump 7 after passing through the annular channel around the drainage pump motor 9 . When the liquid passes through the annular channel around the drainage pump motor 9, it can dissipate heat and cool down the drainage pump motor 9, protect the drainage pump motor 9 from stable operation, and prolong the service life.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com