Azeotropic distillation method for water-containing acetic acid containing aromatic hydrocarbon

A technology for water-containing acetic acid and aromatic hydrocarbons, which is used in distillation purification/separation, chemical instruments and methods, preparation of organic compounds, etc., and can solve the problems of inability to extract alkylbenzene in concentration, large changes in intermediate extraction composition, and no distillation. , to achieve the effect of stable dehydration composition, restraining loss and reducing processing load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

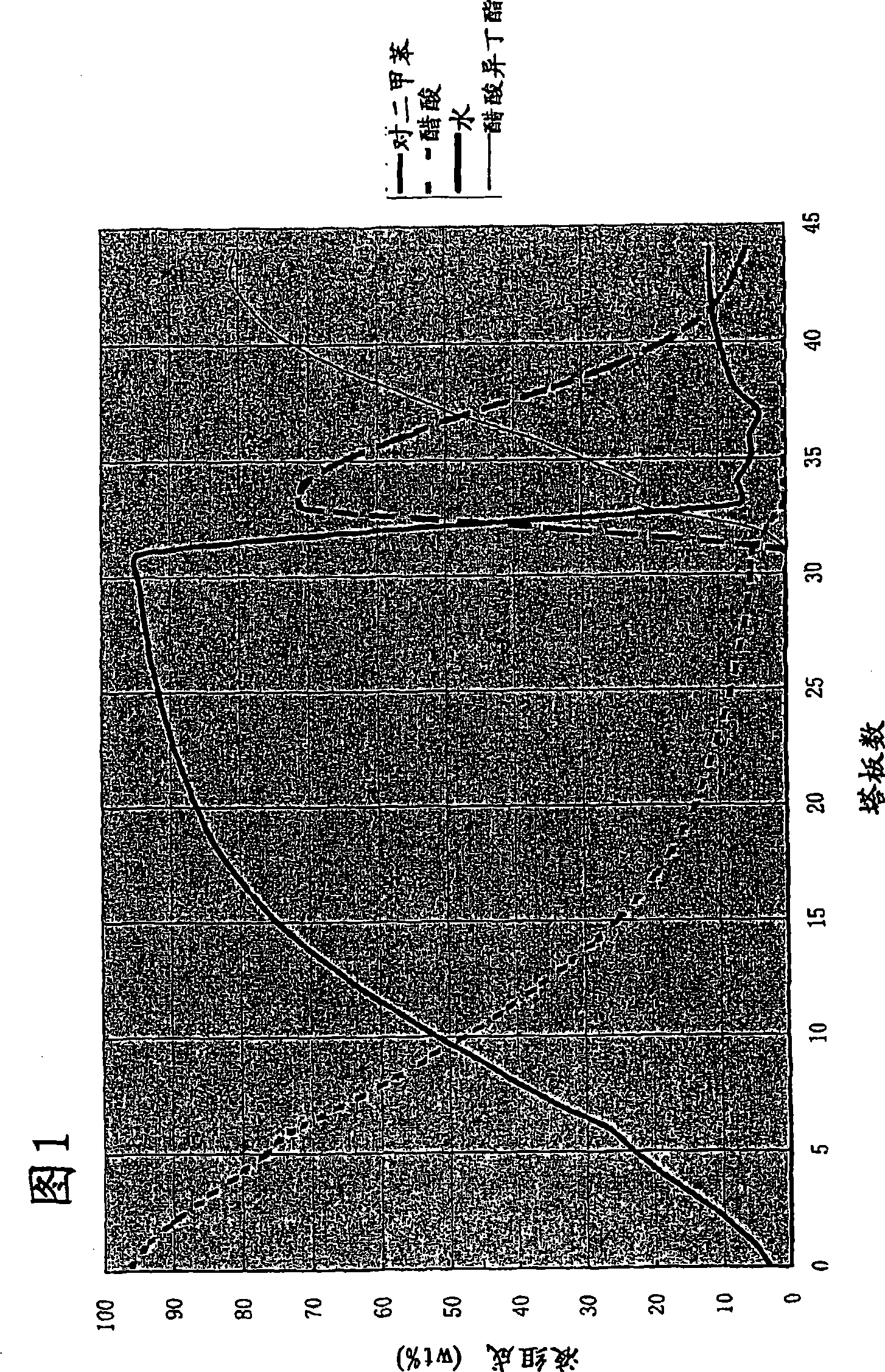

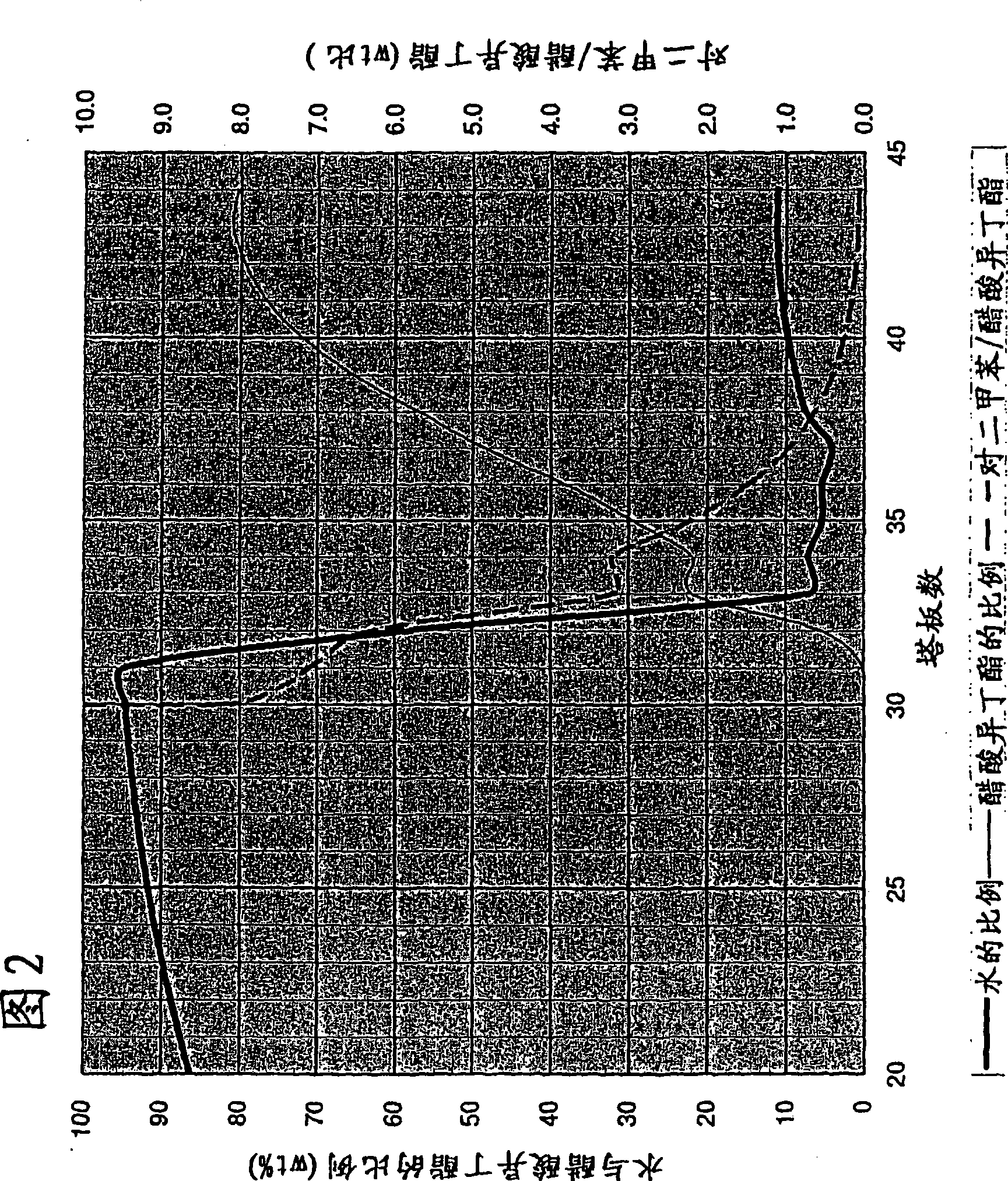

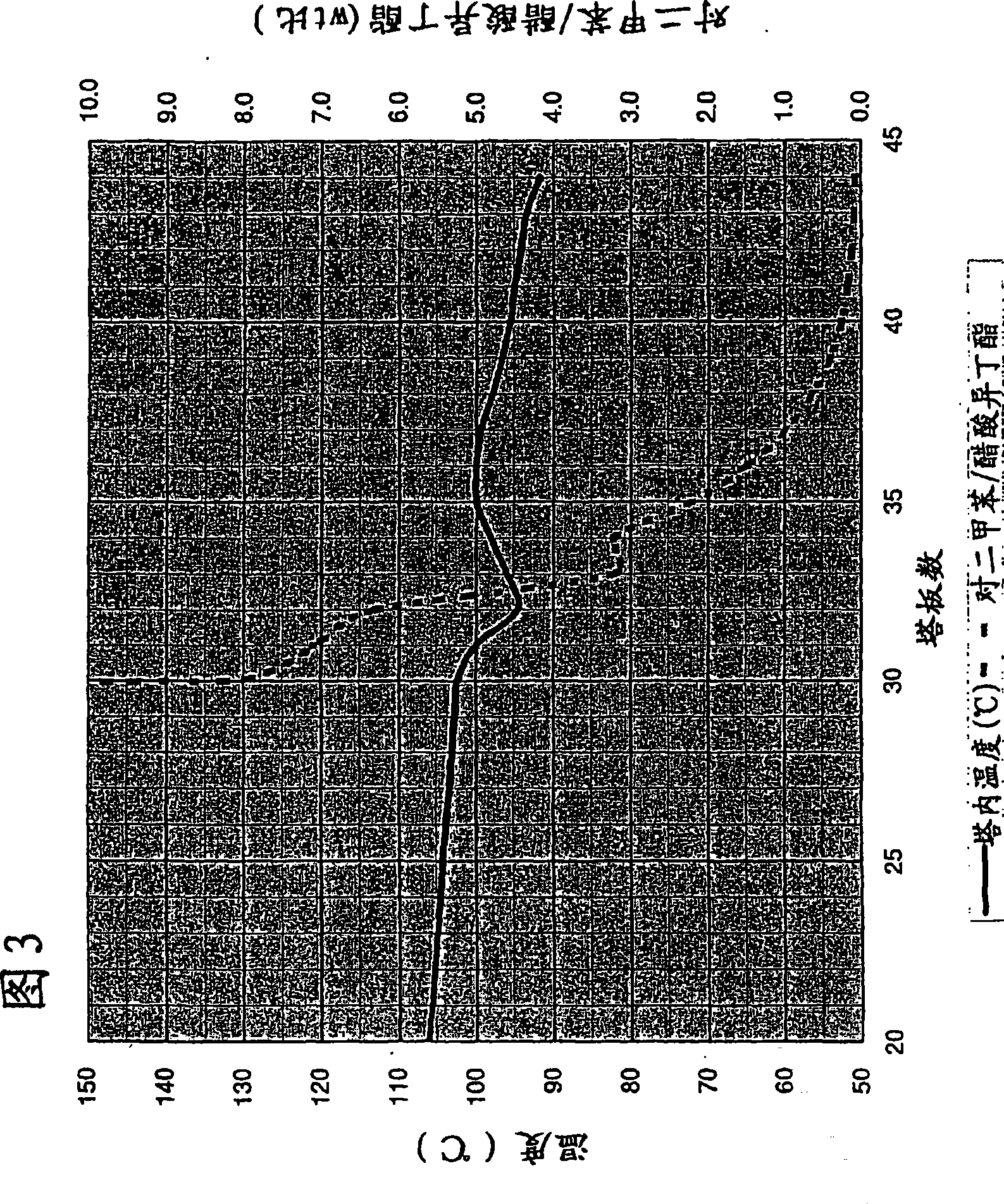

[0100] In the acetic acid recovery system in the terephthalic acid manufacturing process, use the azeotropic distillation column 1 of tray type (actual plate number 80 trays), adopt the azeotropic distillation method that uses isobutyl acetate as entrainer to acetic acid for dehydration, using Figure 4 The flow process step of representation reclaims acetic acid, extracts the distillate that contains p-xylene and reclaims. Figure 5 It shows the operation steps for recovery of dialkylbenzene in the present invention.

[0101]Feed composition is to assume that the concentration of water collected from the production of terephthalic acid is about 20% by weight, about 46% by weight, and about 88% by weight of acetic acid recovery lines 11, 12, 13, respectively connected to the bottom of the distillation column 1 The 7th tray of the actual number of trays (the 4th tray of the theoretical number of trays), the 15th tray of the actual number of trays (the 9th tray of the theoretica...

Embodiment 2

[0111] Further continue the operation of the distillation tower in Example 1. At the same time, after the contents are discharged on the 50th day of Embodiment 1, the controller 24 starts the cycle again. Because the hydrocarbons containing p-xylene are accumulated without interruption, the distillation tower 1 is continued. (the 57th tray of the actual number of trays)-storage tank 3-: the circulation of the distillation column 1 (the 58th tray of the actual number of trays). The PX concentration was concentrated to 55.91 wt% on the 11th day from the restart cycle, and the PX / IBA concentration ratio increased to 1.33. In addition, the temperature of the 57th plate of the actual number of plates of the distillation column 1 at this time was 98.6 degreeC.

[0112] Then, the controller 24 performs control to interrupt the above-mentioned circulation similarly to Example 1, and recovers the distillate organic phase in the distillate storage tank 3 . In addition, the same as in E...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com