Surface treatment method for antiknocking and modifying granulated fertilizer containing ammonium nitrate

A granular fertilizer and surface treatment technology, applied in ammonium nitrate fertilizer, nitrogen fertilizer, fertilization equipment, etc., can solve the problems that are not conducive to large-scale production of granular ammonium nitrate, inconvenient to obtain solid granular fertilizer, and difficult to cool slurry-like materials in time. , to achieve significant anti-knock effect, strong water absorption performance, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

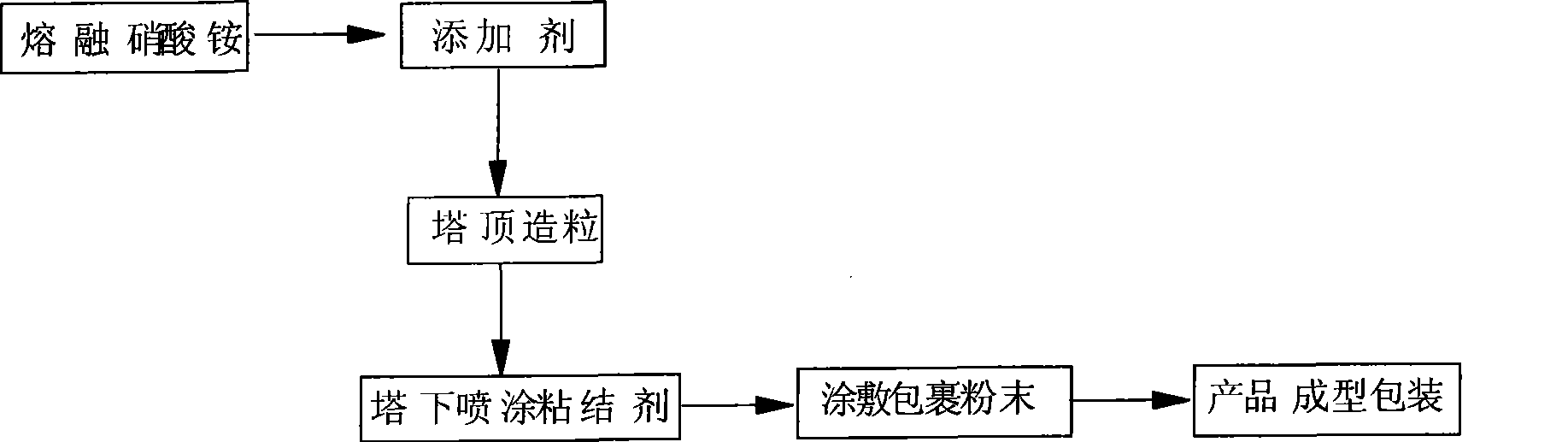

Method used

Image

Examples

Embodiment 1

[0027] Raw material ratio is:

[0028] Pure granular ammonium nitrate: 80%; binder: a mixture of urea and sulfuric acid, 12.5%; curing agent: calcium carbonate, 5%; dusting agent: talcum powder, 2.5%.

[0029] The antiknock modified surface treatment of granular ammonium nitrate includes the following steps:

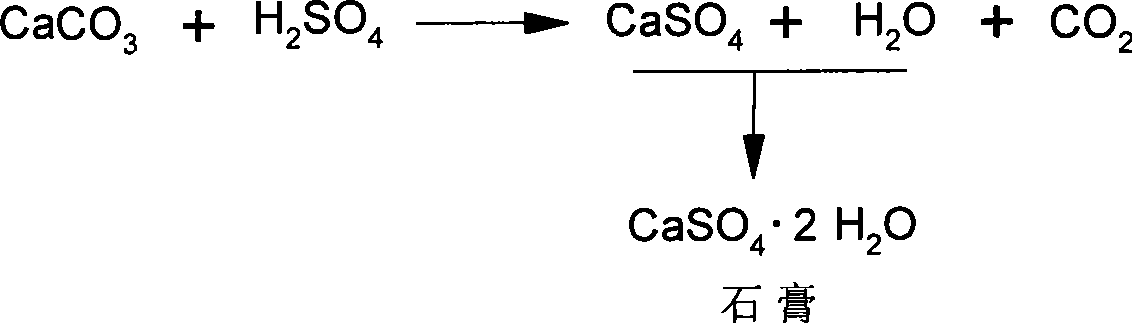

[0030] 1. Preparation of binder: Add 12.2g of water and 100g of concentrated sulfuric acid with a concentration of 98% in sequence in a 500ml glass reactor, start stirring, add 600g of urea evenly and slowly, control the heating rate, and make the temperature of the material in the reactor The maximum temperature should not exceed 130°C, and keep warm at 110°C-120°C to make it in a liquid state for standby use. The molar ratio of urea to sulfuric acid is 10:1, and the moisture content in the binder is 2%;

[0031] 2. Heat 2000g of granular ammonium nitrate and a glass bottle with a volume of 2L in an oven at 70°C to 75°C and keep it warm for 1 hour, and set aside;

[0...

Embodiment 2

[0039] Raw material ratio is:

[0040] Pure granular ammonium nitrate: 50%; binder: a mixture of urea and sulfuric acid, 20%; curing agent: potassium carbonate, 17.5%; dusting agent: ammonium dihydrogen phosphate, 12.5%.

[0041] The antiknock modified surface treatment of granular ammonium nitrate includes the following steps:

[0042] 1. Preparation of binder: Add 50g of concentrated sulfuric acid with a concentration of 98% into a 500ml glass reactor, start stirring, add 200g of urea evenly and slowly, and control the heating rate so that the maximum temperature of the material in the reactor does not exceed 130°C , after the urea is completely dissolved, then add 50g of oleum and 200g of urea in turn, keep warm at 110°C to 120°C, make it in a liquid state for later use, the above ratio, the molar ratio of urea to sulfuric acid is 6.6:1, The moisture content in the agent is 0.2%;

[0043] 2, the insulation of granular ammonium nitrate and glass bottle is with embodiment 1...

Embodiment 3

[0053] Raw material ratio is:

[0054] Pure granular ammonium nitrate: 85%; binder: a mixture of urea and sulfuric acid, 10%; curing agent: magnesium carbonate, 5%.

[0055] The antiknock modified surface treatment of granular ammonium nitrate includes the following steps:

[0056] 1, the preparation of binding agent: with embodiment 1;

[0057] 2, the insulation of granular ammonium nitrate and glass bottle is with embodiment 1;

[0058] 3. Weigh 200g of the binder prepared in step 1 and 1700g of granular ammonium nitrate at a temperature of 70°C to 75°C and pour them into an insulated 2L glass bottle in turn, and mix evenly so that the surface of the granular ammonium nitrate is evenly coated with a layer of sticky Binder;

[0059] 4. Weigh 100g of magnesium carbonate powder and pour it into the glass bottle of step 3, so that it is evenly mixed with the granular ammonium nitrate coated with binder, and the antiknock modified surface treatment of the granular ammonium nit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com