Titanate radical manganese lithium/carbon composite anode material for chargeable lithium battery and preparation method thereof

A technology of lithium manganese titanate and cathode material, applied in electrode manufacturing, battery electrodes, circuits, etc., can solve problems such as poor conductivity, and achieve the effect of easy operation, high cost performance, and improved electrochemical performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

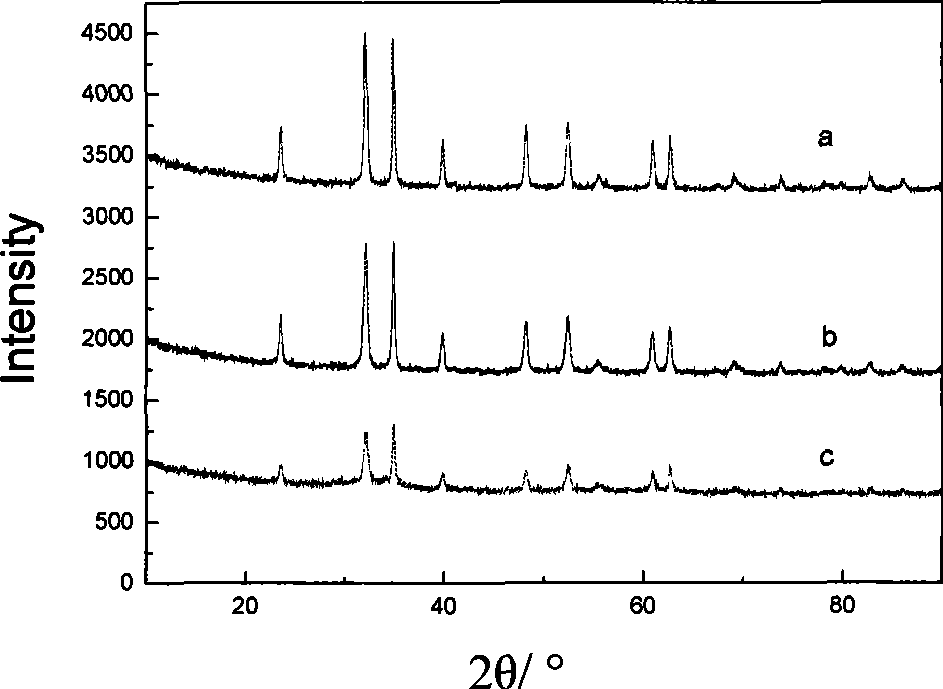

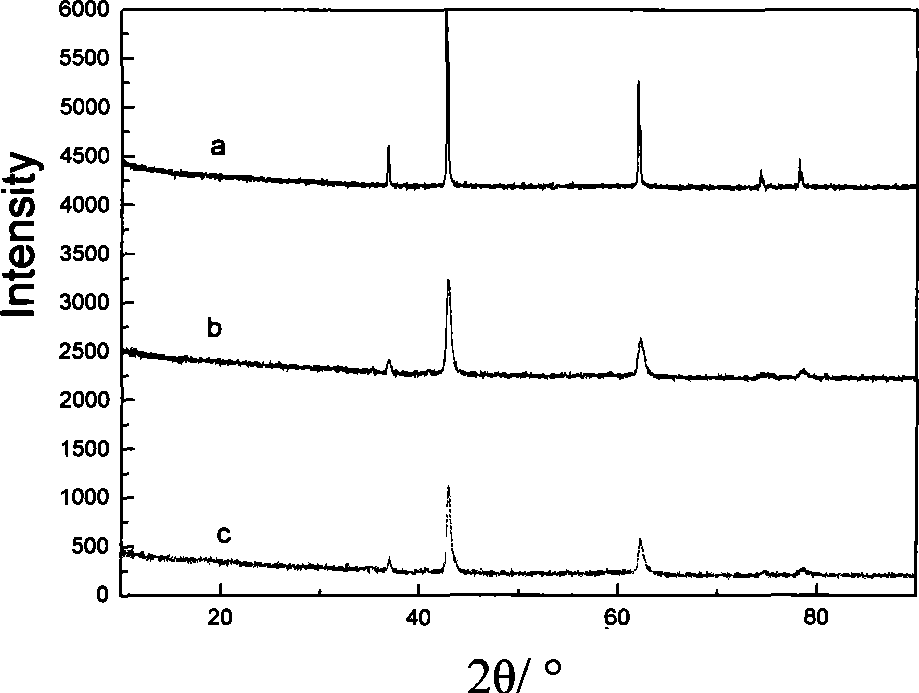

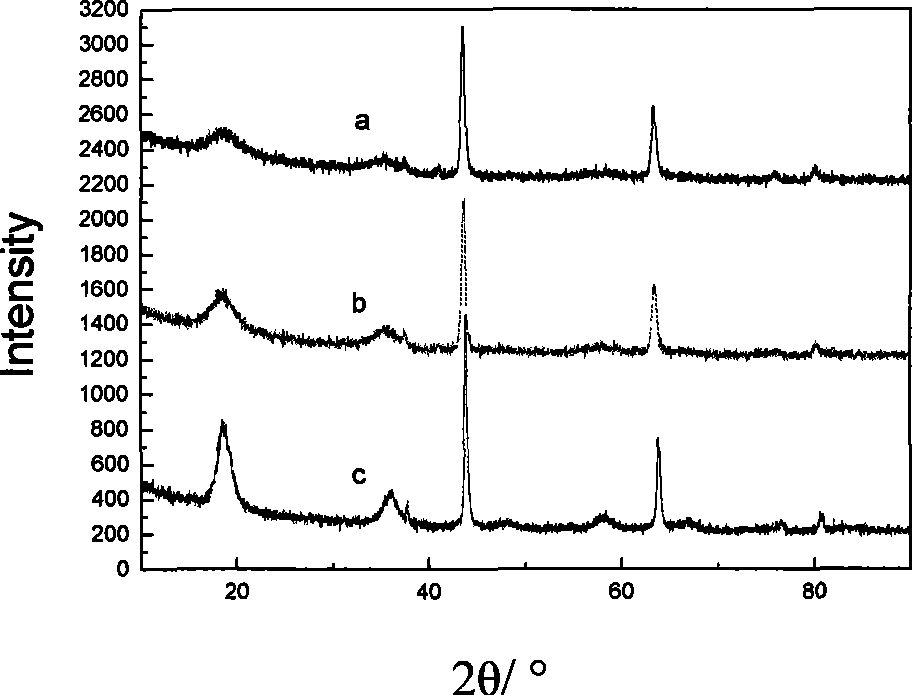

Embodiment 1

[0031] 4.9g Mn(Ac) 2 4H 2 O and 6.8g Ti(OC 4 h 9 ) 4 Add it to 20ml of ethanol, react in a sealed flask at 30°C for 24h, transfer to an evaporating dish for drying at 80°C, then transfer to a tubular resistance furnace, and heat treat at 800°C for 3h under the protection of nitrogen to obtain MnTiO 3 Material. 2.27g MnTiO 3 material and 1.26 g LiOH H 2 O, and 0.3g sucrose with 30ml acetone as a dispersant, ball milled for 5h (rotation speed 500r / min). After the acetone is volatilized, it is transferred to a porcelain boat, placed in a tubular resistance furnace under the protection of Ar, heat-treated at 1050 °C for 3 h, and cooled naturally to room temperature to obtain Li 2 MnTiO 4 / C Composite. Will Li 2 MnTiO 4 / C composite material was heated in the air at 180°C for 10 hours, washed and filtered with water several times after cooling, and after the filtrate was neutral, it was dried at 120°C to obtain the Li 2-x MnTiO 4 / C Composite. In the total mass of thi...

Embodiment 2

[0033] 9.8g Mn(Ac) 2 4H 2 O and 3.2 g TiO 2 Add it to 40ml of ethanol, react in a sealed flask at 70°C for 12h, transfer it to an evaporating dish for drying at 120°C, and then transfer it to a tube-type resistance furnace, heat treatment at 700°C for 3h under nitrogen protection, and obtain MnTiO 3 Material. 2.27g MnTiO 3 material and 1.26 g LiOH H 2 O, and 1.5g of sucrose with 20ml of acetone as a dispersant, ball milled for 5h (rotation speed 500r / min). After the acetone is volatilized, it is transferred to a porcelain boat and placed in a tubular resistance furnace under the protection of N2, heat-treated at 900°C for 10h, and naturally cooled to room temperature to obtain the Li 2 MnTiO 4 / C Composite. Will Li 2 MnTiO 4 / C composite material was heated in the air at 160°C for 24 hours, washed and filtered with water several times after cooling, and after the filtrate was neutral, it was dried at 120°C to obtain the Li 2-x MnTiO 4 / C Composite. In the total mas...

Embodiment 3

[0035] 4.9g Mn(Ac) 2 4H 2 O and 6.8g Ti(OC 4 h 9 ) 4 Add it to 20ml of ethanol, react in a hydrothermal kettle at 150°C for 24h, transfer it to an evaporating dish for drying at 90°C, then transfer it to a tubular resistance furnace, and heat-treat it at 500°C for 5h under the protection of nitrogen to obtain MnTiO 3 Material. 2.27g MnTiO 3 material and 1.26 g LiOH H 2 O, and 1.5g of sucrose with 30ml of acetone as a dispersant, ball milled for 5h (rotation speed 500r / min). After the acetone is volatilized, it is transferred to a porcelain boat and placed in a tube resistance furnace under N 2 Under protection, heat treatment at 900°C for 10h, and naturally cool to room temperature, the Li 2 MnTiO 4 / C Composite. Will Li 2 MnTiO 4 / C composite material was heated in the air at 180°C for 10 hours, washed and filtered with water several times after cooling, and after the filtrate was neutral, it was dried at 120°C to obtain the Li 2-x MnTiO 4 / C Composite. In the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com