Method for preparing aminoglutaric acid modified expanded graphite and use in methyl aldehyde gas adsorption

A technology of expanded graphite and formaldehyde gas, which is applied in separation methods, chemical instruments and methods, and other chemical processes to achieve the effects of increasing surface activity, increasing adsorption capacity, and increasing pore volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

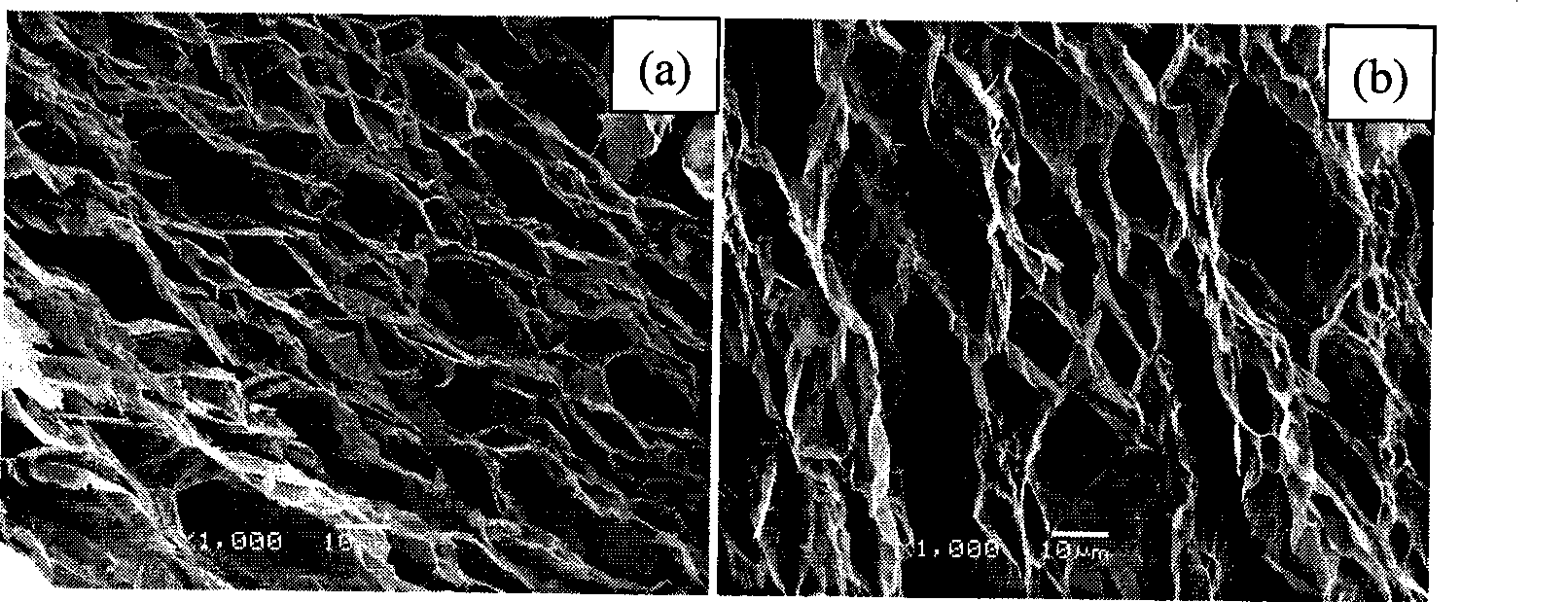

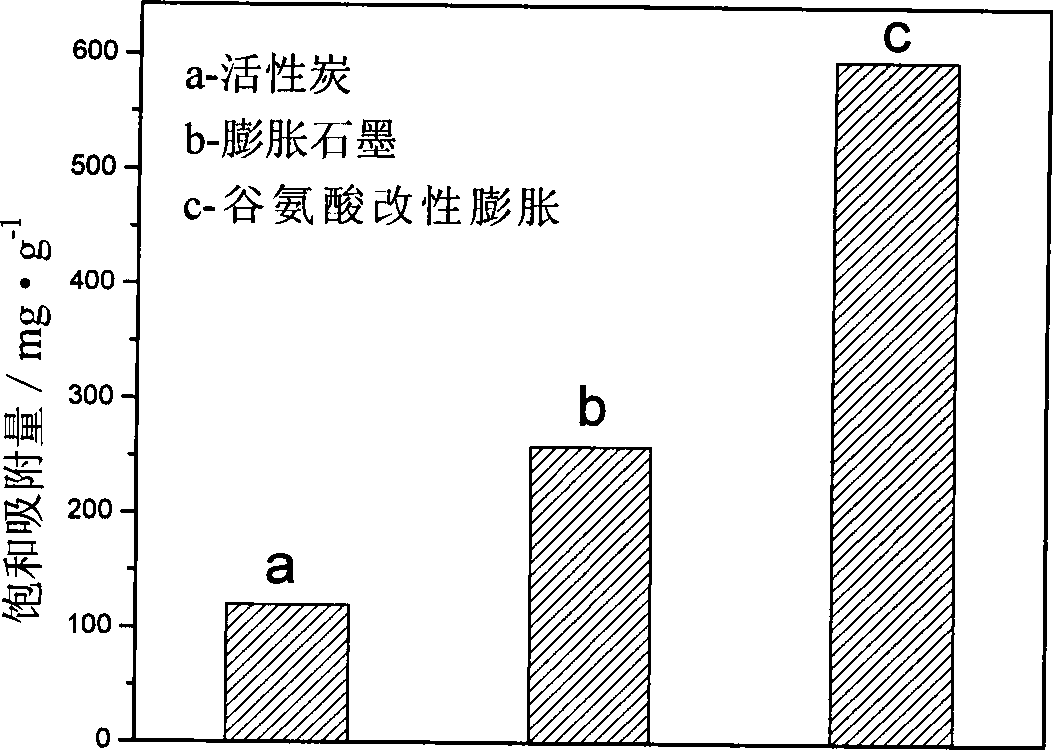

[0010] Example 1: A certain amount of expandable graphite prepared from natural flake graphite is soaked in a 0.1mol / L glutamic acid solution at a certain temperature, washed with water, dried, and expanded to obtain a modified expanded graphite. graphite. The mass ratio of expandable graphite to glutamic acid is 1:0.1, the immersion temperature is 40°C, and the immersion time is 1.5h. The obtained modified expanded graphite is subjected to a static adsorption test on formaldehyde gas at room temperature, and the maximum adsorption amount can reach 310 mg / g.

Embodiment 2

[0011] Embodiment 2: according to the preparation method described in embodiment 1, expanded graphite is soaked in the glutamic acid solution of 1.0mol / L, the mass ratio of expanded graphite and glutamic acid is changed into 1:0.3, soaking temperature is 40°C, soaking time is 1.5h. The prepared modified expanded graphite was subjected to a static adsorption test on formaldehyde gas at room temperature, and the maximum adsorption amount could reach 596mg / g.

Embodiment 3

[0012] Example 3: According to the preparation method described in Example 1, the mass ratio of expanded graphite and glutamic acid was changed to 1:0.4, the soaking temperature was 40°C, and the soaking time was 1.5h. The prepared modified expanded graphite was subjected to a static adsorption test on formaldehyde gas at room temperature, and the maximum adsorption amount could reach 532 mg / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Maximum adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com