Technique for preparing edible rice protein and thin rice-flour noodles with coproduction of broken rice

A preparation process and rice protein technology, applied in the field of deep processing of grains, can solve the problems of many broken strips, serious adhesion, poor toughness, etc., and achieve the effects of reducing waste water discharge, improving comprehensive utilization, and strong operability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

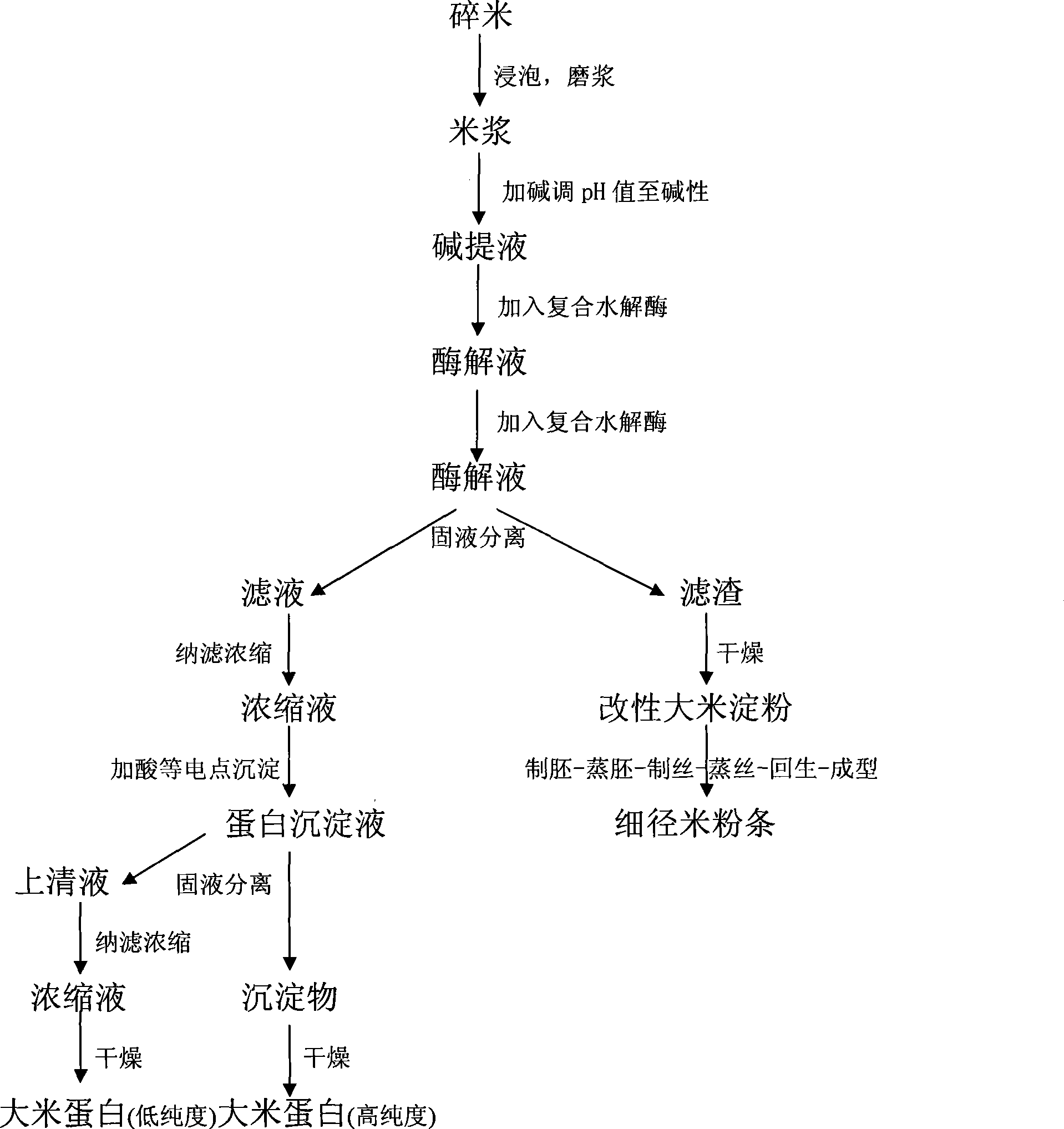

Image

Examples

Embodiment 1

[0020] Take 5Kg of broken rice, add 10L of water to soak overnight, use wet grinding after soaking, add water after refining to a total volume of 16.67L, that is, the ratio of solid to liquid is 3:7. Then add 0.3% NaOH, stir and mix at 50°C; first add compound hydrolase, 0.3% alkaline protease, the reaction temperature is 50 degrees, enzymolysis reaction 4h, then add compound hydrolase, neutral protease 0.2%, react The temperature is 50 degrees, and the enzymolysis reaction is 4 hours; after the reaction is completed, the plate and frame are filtered, and the filter residue is dried to become the modified rice starch; the filtrate is concentrated by a nanofiltration system until the solid concentration is about 10-20%. HCl adjusts the pH value to 5.0 for isoelectric point precipitation, and the precipitate obtained after centrifugation is dried to obtain high-purity rice protein; the supernatant is then concentrated by a nanofiltration system to a concentration of about 20%. T...

Embodiment 2

[0022] Take 1.5Kg of broken rice, add 3L of water to soak overnight, use wet refining after soaking, add water after refining to a total volume of 5L, that is, the ratio of solid to liquid is 3:7. Then add 0.3% NaOH, stir and mix evenly at 50°C; first add compound hydrolase, 0.3% alkaline protease, carry out enzymolysis reaction, enzymolysis reaction 5h; then add compound hydrolase, neutral protease 0.1%, reaction temperature is 50 degrees, enzymolysis reaction 5h. After the reaction is completed, the plate and frame are filtered, and the filter residue is dried to become modified rice starch; the filtrate is concentrated by a nanofiltration system to a concentration of 10-20%, and the pH value is adjusted to 5.0 with HCl for isoelectric point precipitation. After centrifugation The obtained precipitate is dried to obtain high-purity rice protein; the supernatant is concentrated by a nanofiltration system to a concentration of about 20%, and the concentrated solution is spray-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com