Operable transmission, working fluid for such a transmission, and method for commissioning the same

A transmission mechanism and fluid technology, applied in transmissions, gear transmissions, transmission parts, etc., can solve problems such as inferior hydrothermal characteristics, and achieve the effect of less structure space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

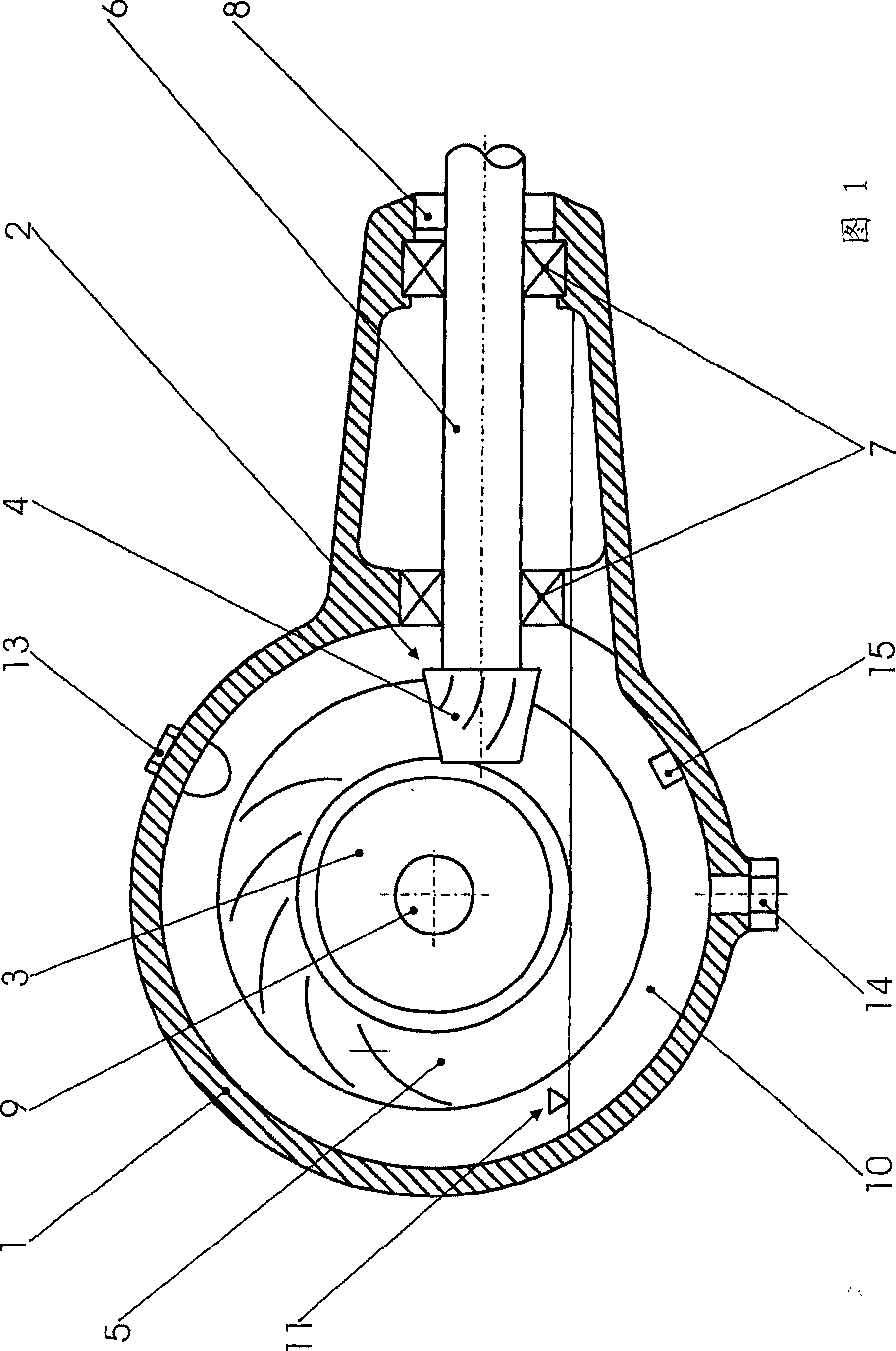

[0027] FIG. 1 shows an arbitrary standard transmission, here a front axle drive of a motor vehicle with a hypoid drive and a differential drive. It can likewise be used in transfer cases or reduction gears of drives of machines (for example in the food industry). The hypoid gear transmission mechanism 2 and the differential transmission mechanism 3 are located in the housing 1 . The hypoid gear transmission mechanism 2 is composed of a driving gear 4 and a ring gear 5 placed on a shaft 6 . The shaft 6 passes through a bearing 7, outside which a sealing ring 8 is attached. The differential gear 3 is also of conventional construction and is therefore not sectioned. Visible is an axle shaft 9 extending towards the gear.

[0028] There is an oil tank 10 below the inside of the housing, and the fluid level of the oil tank is indicated by 11 in the shutdown state. The ring gear is submerged in the oil sump 10 . Also, a filling opening, an air vent 13, an outlet 14 for lubricati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com