Single-walled carbon nanotube, carbon fiber aggregate containing the single-walled carbon nanotube, and method for production of the single-walled carbon nanotube or the carbon fiber aggregate

A technology of single-walled carbon nanotubes and manufacturing methods, which is applied in the direction of single-walled carbon nanotubes, carbon nanotubes, and nanostructure manufacturing, and can solve problems such as thick diameters, unevenness, and failure to meet the requirements of practical applications.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

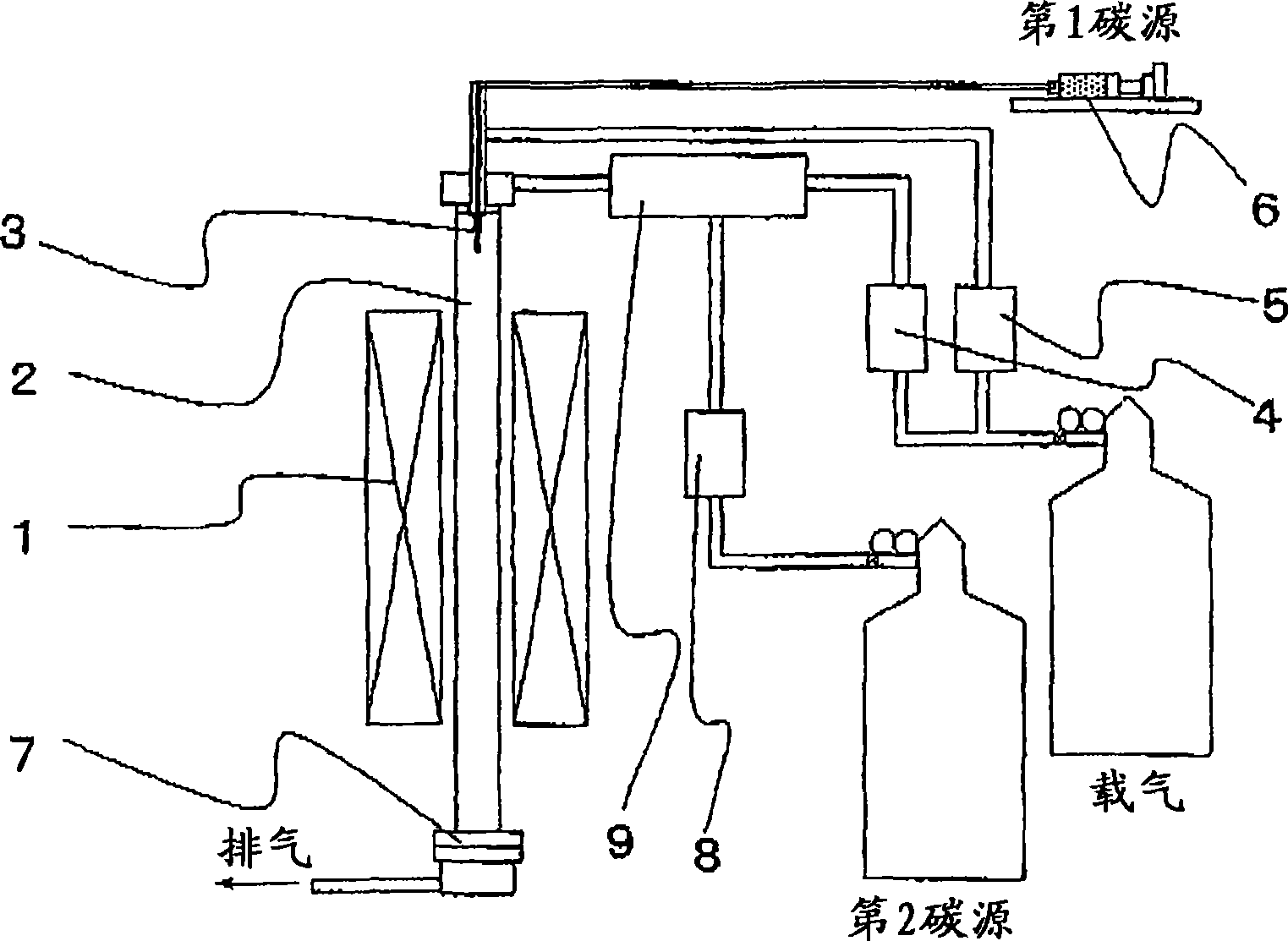

[0085] Such as figure 1 As shown, the single-walled carbon nanotubes of the present invention were produced using a vertical single-walled carbon nanotube production apparatus.

[0086] The device consists of: 4kW electric furnace 1, mullite reaction tube 2 with inner diameter of 5.0cm and outer diameter of 5.5cm, nozzle 3, first carrier gas flow meter 4, second carrier gas flow meter 5, micro-feeding Device 6, recovery filter 7, second carbon source flow meter 8, gas mixer 9.

[0087] Store decalin as the first carbon source, ferrocene as the organotransition metal compound, and thiophene as the organosulfur compound as the raw material solution of 100:4:2 by weight in the trace feeder 6, as the second carbon The source uses ethylene, and the flow rate is controlled through the second carbon source flow meter 8 and the gas mixer 9 .

[0088] Using hydrogen at a flow rate of 7 L / min as a carrier gas, the above-mentioned raw material solution was sprayed at a flow rate of 3.2...

Embodiment 2

[0094] The same test as in Example 1 was performed except that the flow rate of the second carbon source was set to 5.0 sccm and the reaction time was set to 1 hour. The product thus obtained was designated as Sample 2.

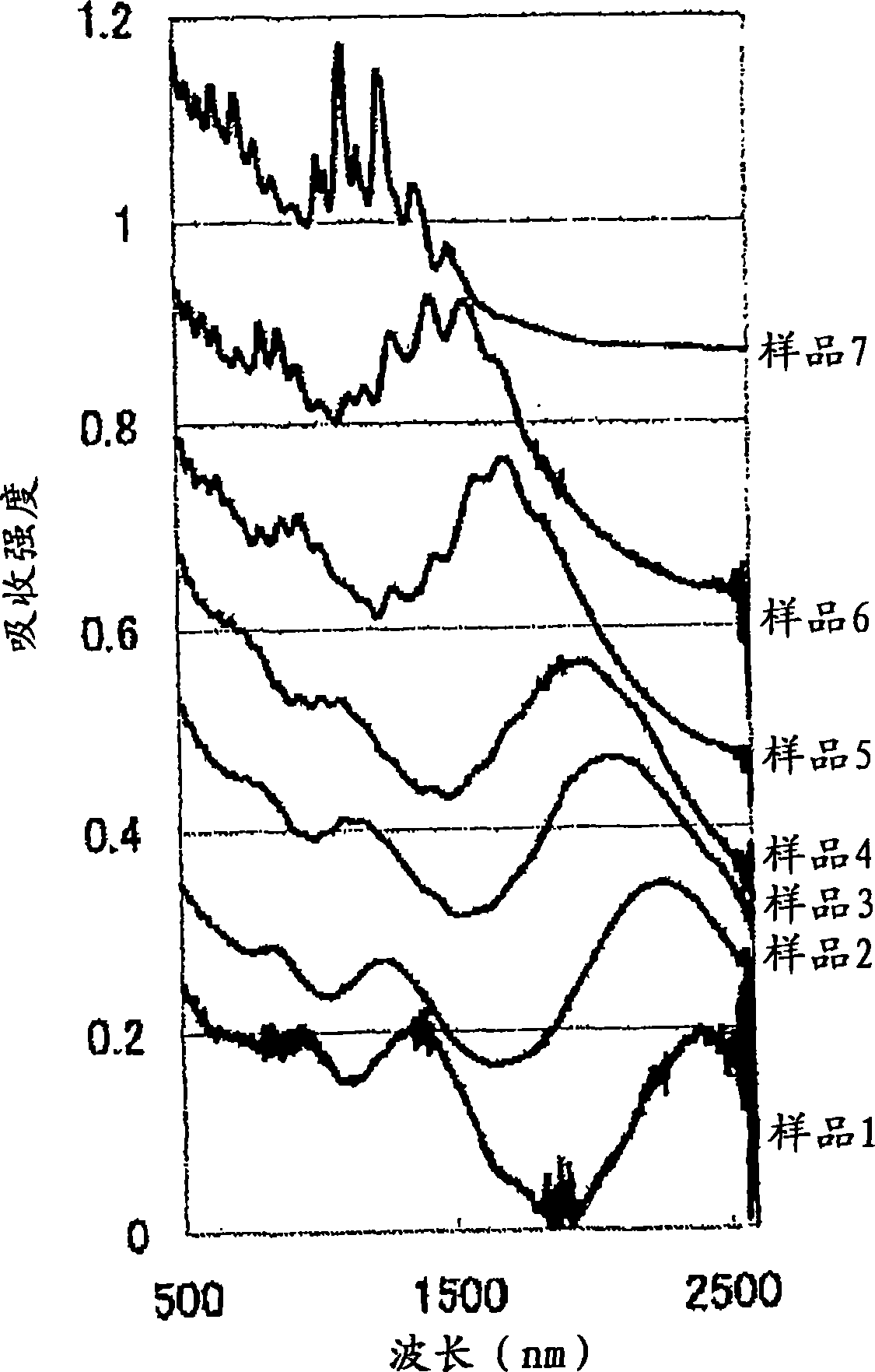

[0095] Yield is 19.5mg, and the diameter distribution of monolayer carbon nanotube is estimated similarly with embodiment 1, result, as figure 2 As shown, a peak at 2285 nm was observed. This corresponds to a diameter of 1.9 nm.

Embodiment 3

[0097] The same test as in Examples 1 and 2 was performed except that the flow rate of the second carbon source was set to 10.0 sccm. The product thus obtained was designated as sample 3.

[0098] Yield is 20.4mg, and the diameter distribution of monolayer carbon nanotube is estimated similarly with embodiment 1, result, such as figure 2 As shown, a peak at 2120 nm was observed. This corresponds to a diameter of 1.7 nm.

[0099] From the results of Examples 2 and 3, it can be concluded that the diameter of the produced single-walled carbon nanotubes is 0.1-0.2 nm smaller than that of Example 1. This means that by properly adjusting the flow rate of the second carbon source, the diameter of the single-walled carbon nanotubes can be precisely controlled in units of about 0.1 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com