Integrated module for digital high frequency switch electromagnetic heating power supply system

A high-frequency switching, heating power technology, applied in induction heating, induction current source, induction heating control and other directions, can solve the problems of uneven power regulation, long development cycle, difficult application and promotion, etc., to improve the smoothness of power regulation , The effect of reducing volume weight and heat generation, and reducing the difficulty of product development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention and its applications will be further described below in conjunction with the contents shown in the accompanying drawings.

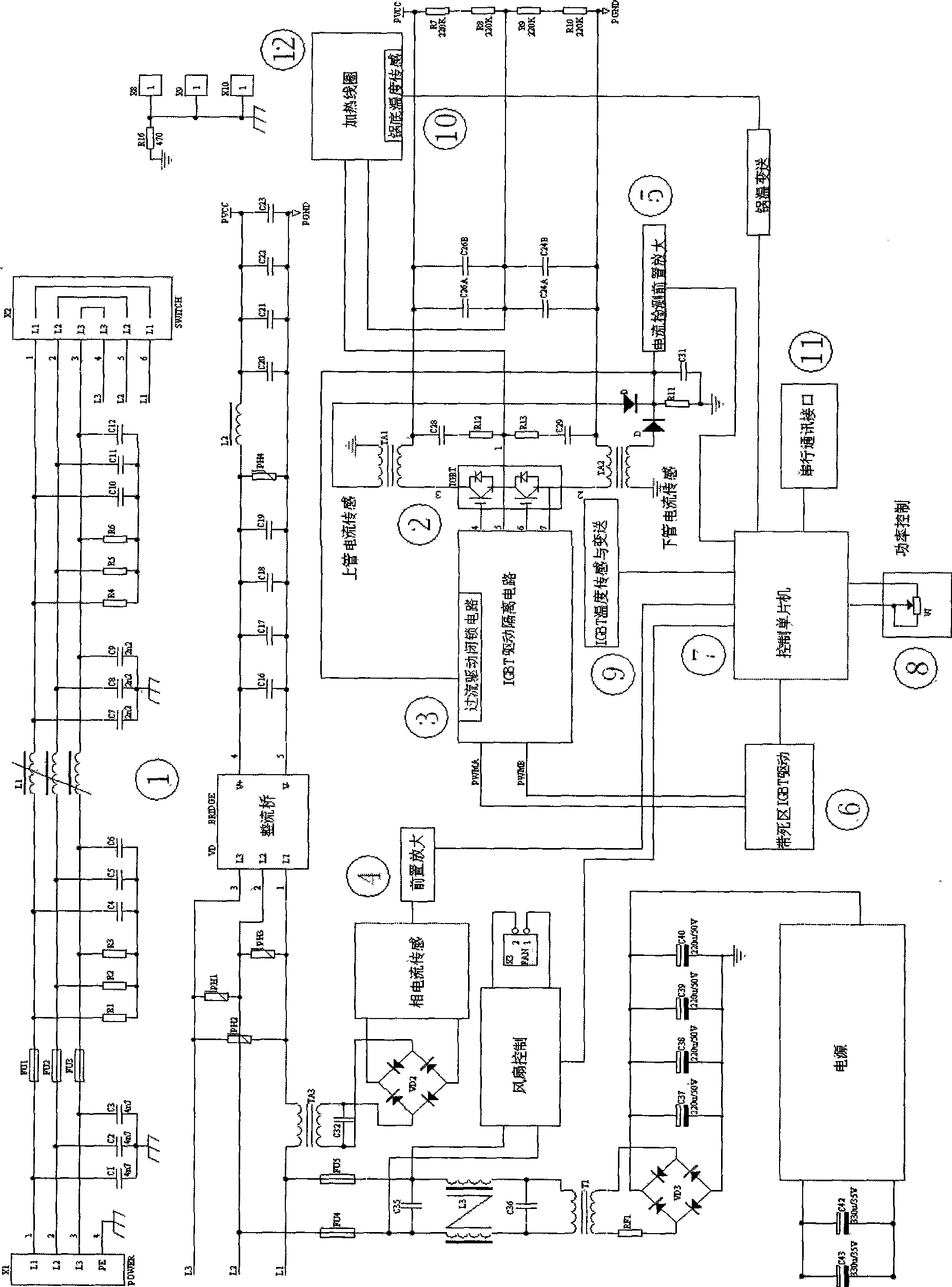

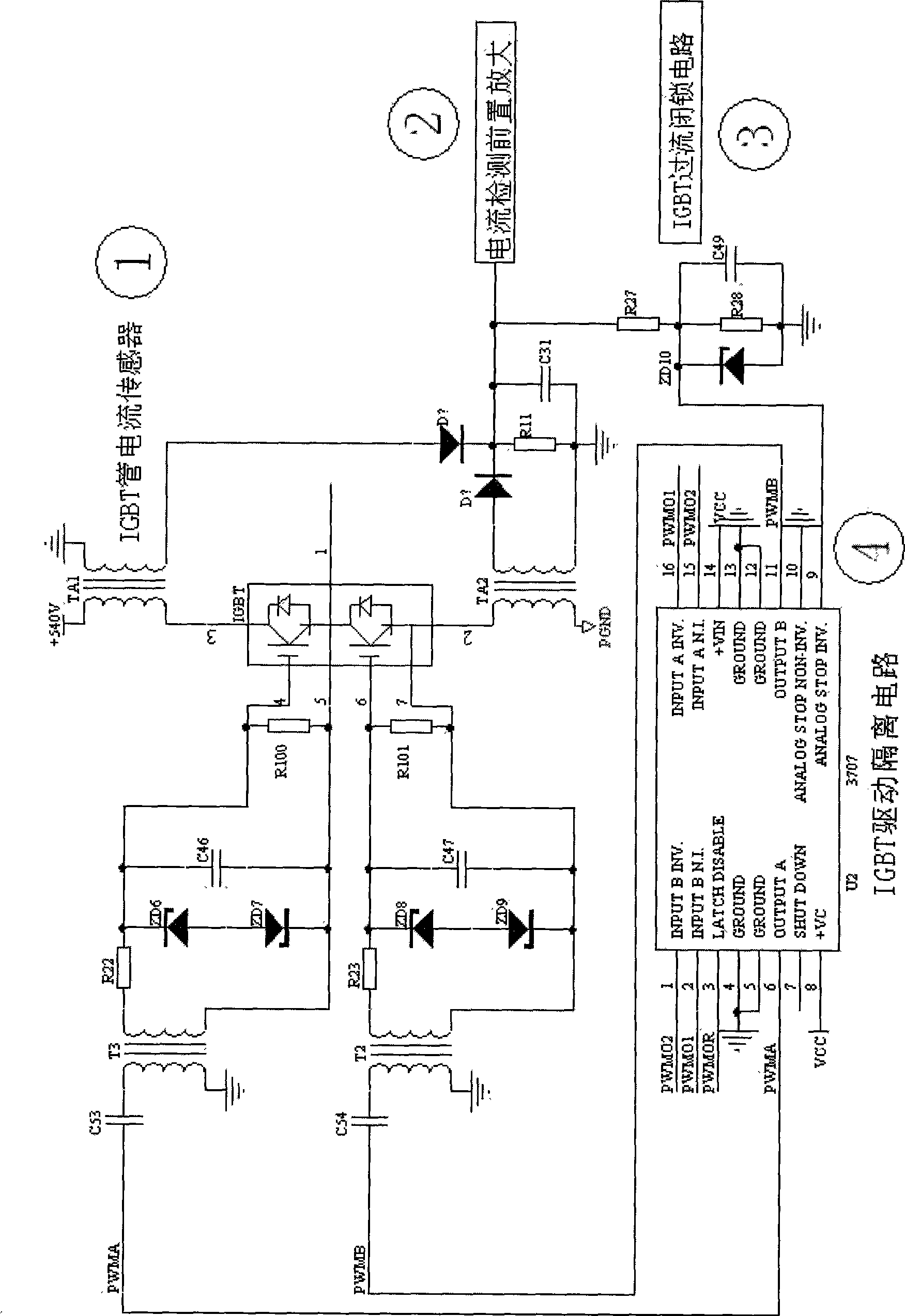

[0025] Such as figure 1 As shown, the application of the digital high-frequency switch electromagnetic heating power supply system integrated module of the present invention is composed of a rectification filter circuit 1, an inverter circuit 2, an IGBT drive isolation circuit 3, an input phase current sampling circuit 4, and an IGBT current sampling circuit 5 , IGBT drive circuit 6, control microcontroller 7, power controller 8, IGBT temperature detection circuit 9, pot bottom temperature detection circuit 10, serial communication interface 11, heating coil 12, and the overall structure of the power module. The control method combining digital pulse frequency modulation and pulse width modulation, by detecting the signal of the power controller 8 and other sampling and feedback signals, controlling the single chip microcomput...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com