Rope wheel type glass elevator

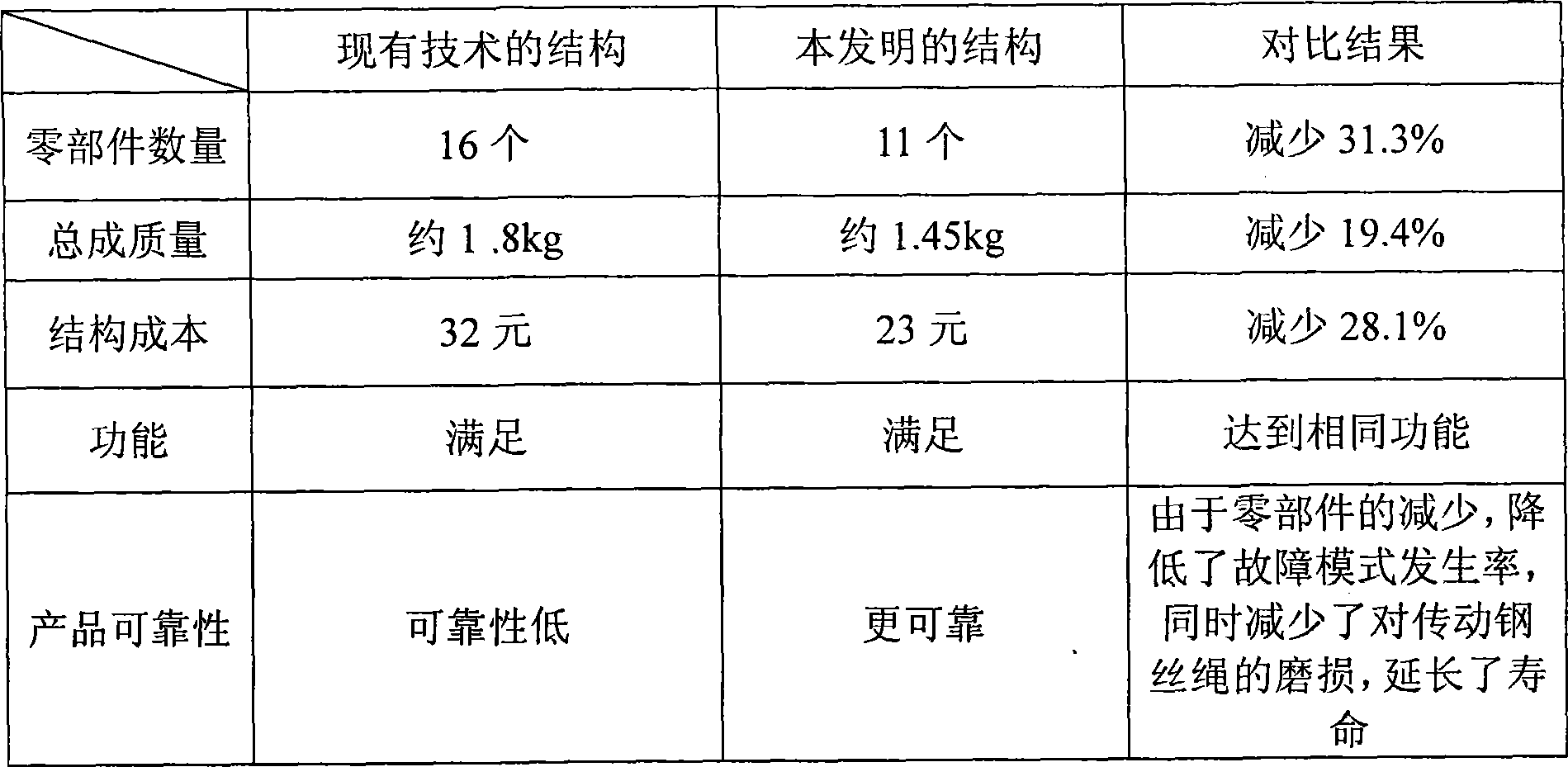

A glass lifter and rope pulley technology, used in windshields, windows, door/window accessories, etc., can solve the problems of cost pressure, complex production and assembly processes, and more failures of parts and components for auto parts manufacturers. To achieve the effect of reducing raw material consumption, weight reduction, and prolonging life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Referring to the accompanying drawings, through the description of the embodiments, the specific implementation of the present invention, such as the shape, structure, mutual position and connection relationship between the various parts, the function and working principle of each part, and the manufacturing process And the method of operation and use, etc., are described in further detail to help those skilled in the art have a more complete, accurate and in-depth understanding of the inventive concept and technical solution of the present invention.

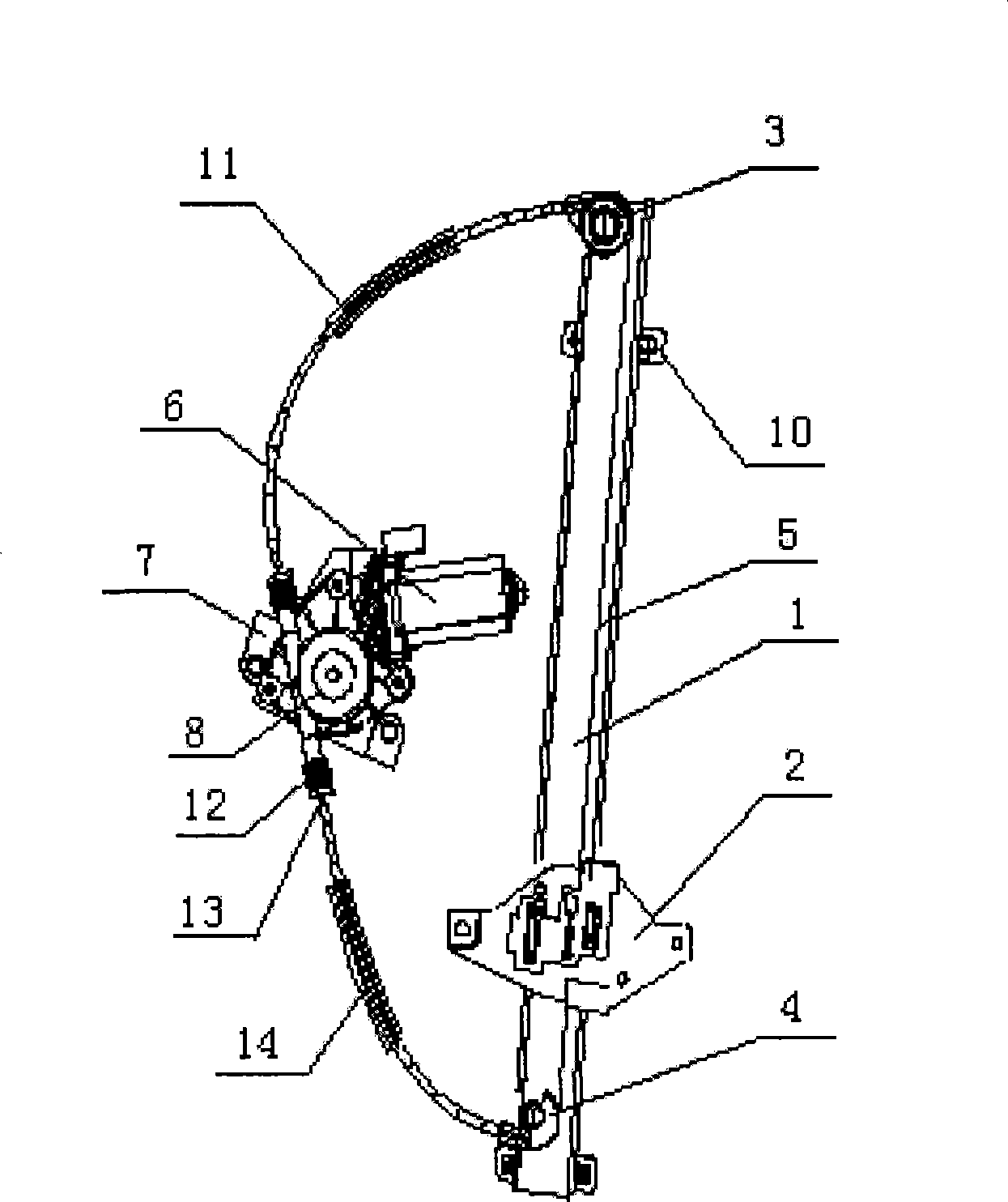

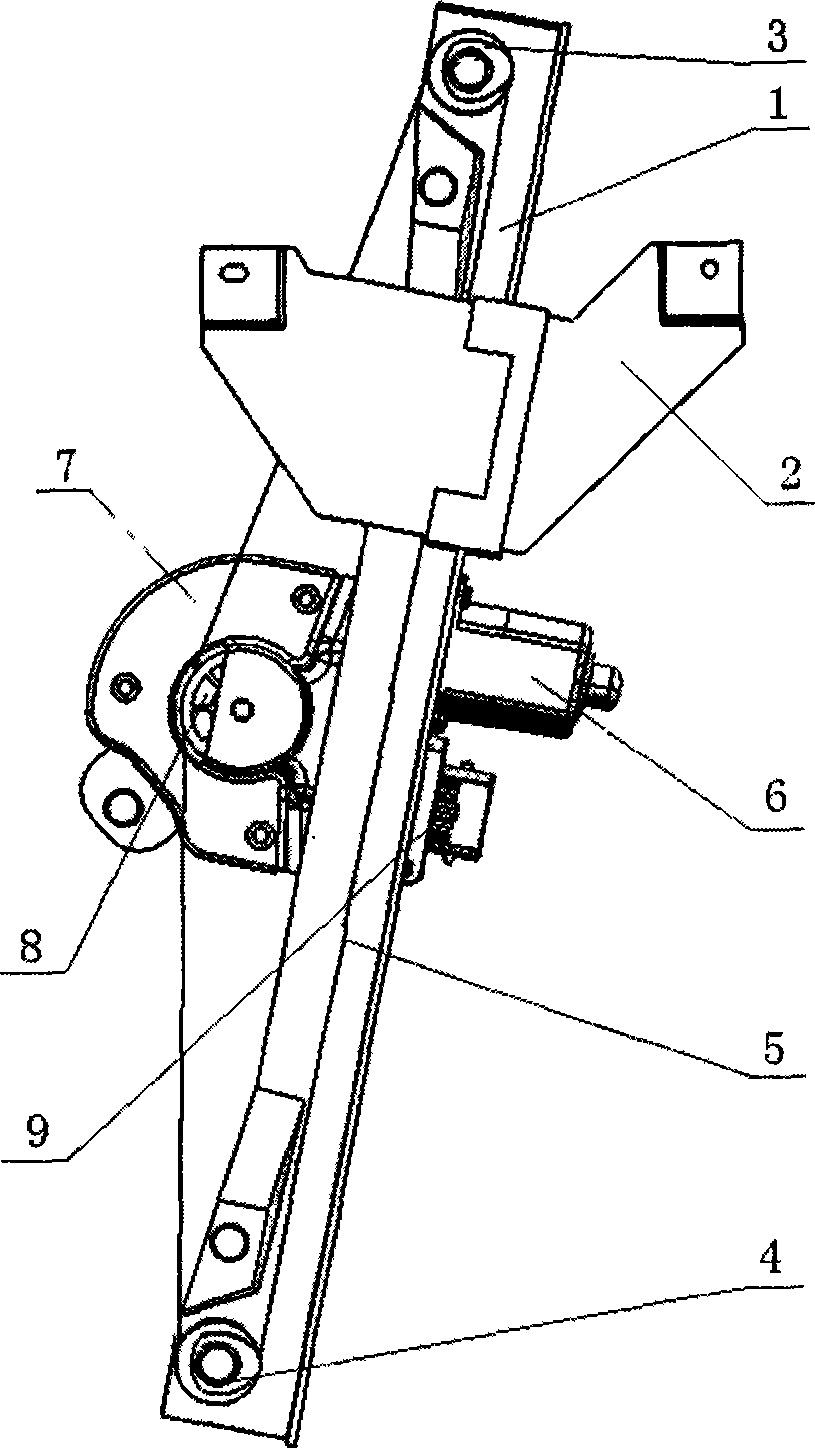

[0016] Such as figure 2 The structure of the present invention expressed as shown, the present invention is a sheave type glass regulator, including a slider 2 connected with the door glass, the slider 2 is connected with a transmission wire rope 5, and placed on the guide rail 1, and the transmission wire rope 5 is wound Over pulley 3 and pulley 4 are connected with rope drum 8, and motor 6 and rope drum 8 are fixed on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com