Needle bed inlaid piece and method of processing the same

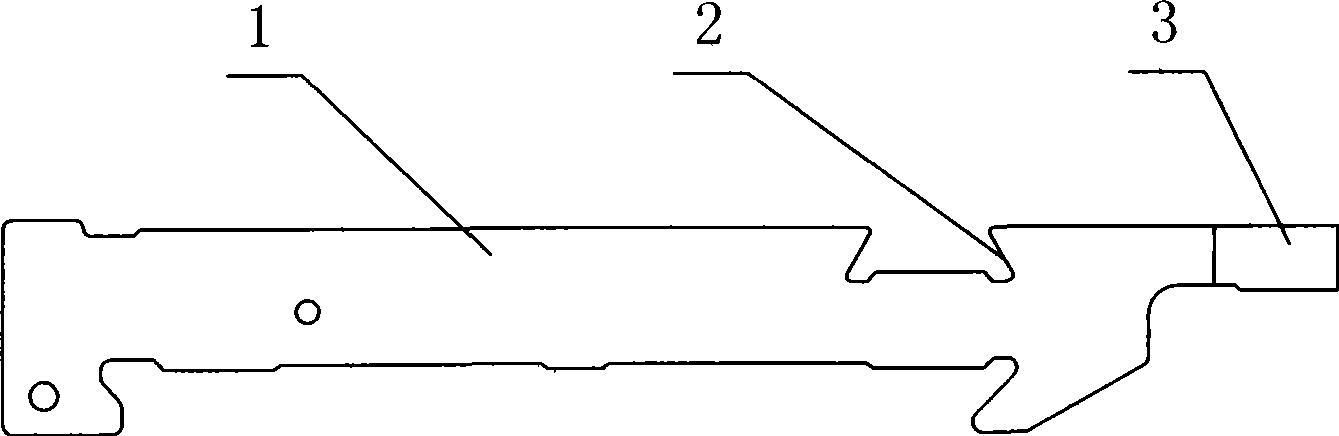

A processing method and paneling technology, applied in knitting, weft knitting, warp knitting, etc., can solve the impact on product appearance and quality, damage to the surface of the needle bed panel, and the large volume of the head 3 of the needle bed panel 1 and other issues to achieve the effect of simplifying the product process, improving precision and quality, and ensuring the quality of the shear surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

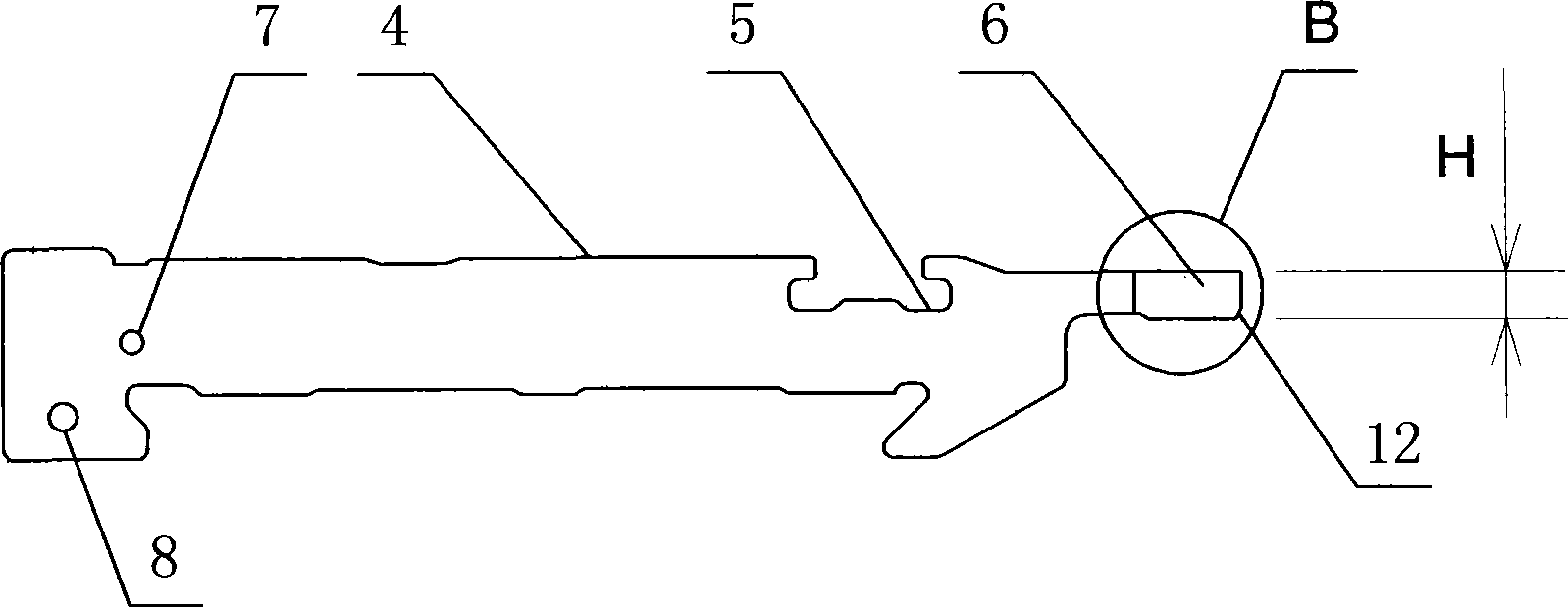

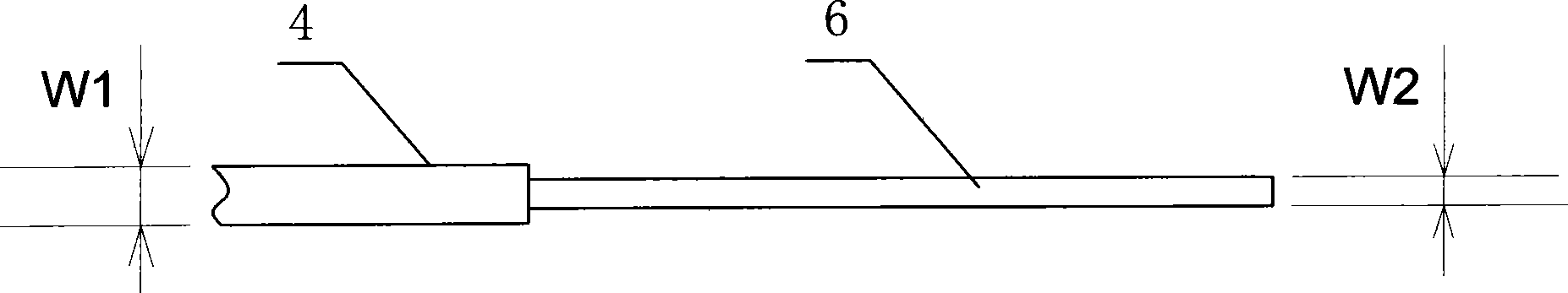

[0030] Such as figure 2 , image 3 As shown, the needle bed insert of the present invention includes a body 4 made of SK5 carbon tool steel, and a straight groove 5 is opened on the upper end of the body 4 . The design of the straight edge groove 5 makes it easy to press the needle bed insert and adjust the gap, so that the product is not easy to deform, and the occurrence of defective products is greatly reduced. At the same time, SK5 carbon tool steel is used as raw material, which greatly improves the product precision and quality.

[0031] In the present invention, a chamfer 12 is provided at the front lower end of the head 6 of the body 4, which shrinks the contact surface between the needle bed insert and other parts, thereby making the use of the needle bed insert more rational.

[0032] As a typical specification of the needle bed insert of the present invention, the thickness W1 of the body 4 is 0.84mm, the thickness error is controlled within the range of 0-0.01mm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface smoothness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com