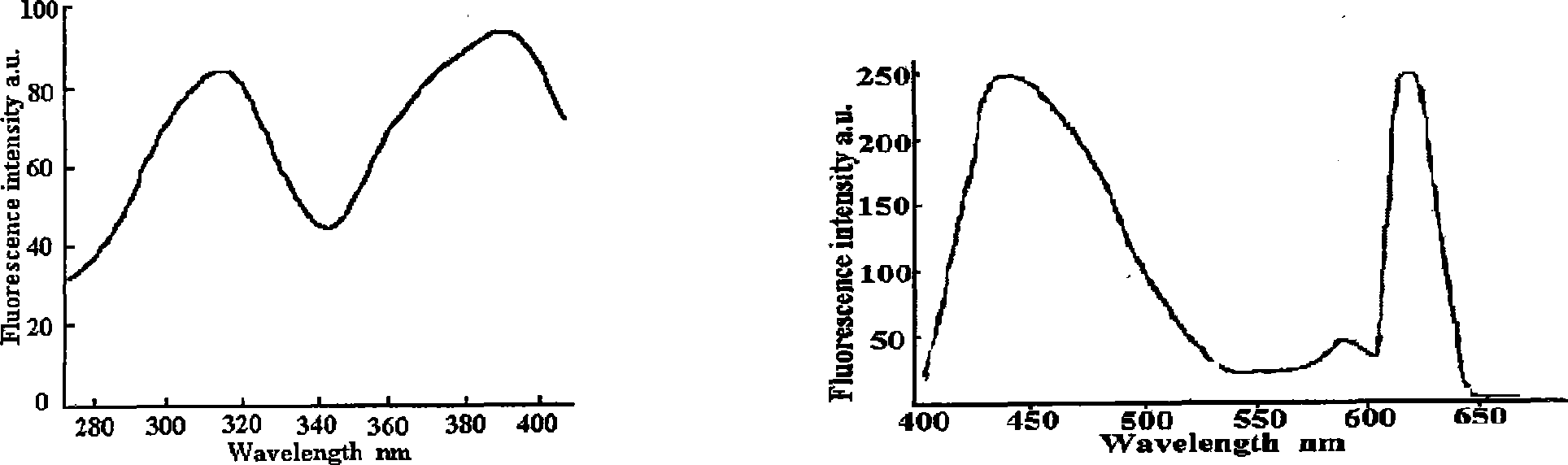

Novel ecology imitating two band optical energy conversion agricultural film and technique for producing the same

A light energy conversion and eco-imitation technology, applied in the field of agriculture, can solve the problems of high cost of light conversion films and restrictions on large-scale promotion and application, and achieve the effects of long life of light conversion, low production cost, and less consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

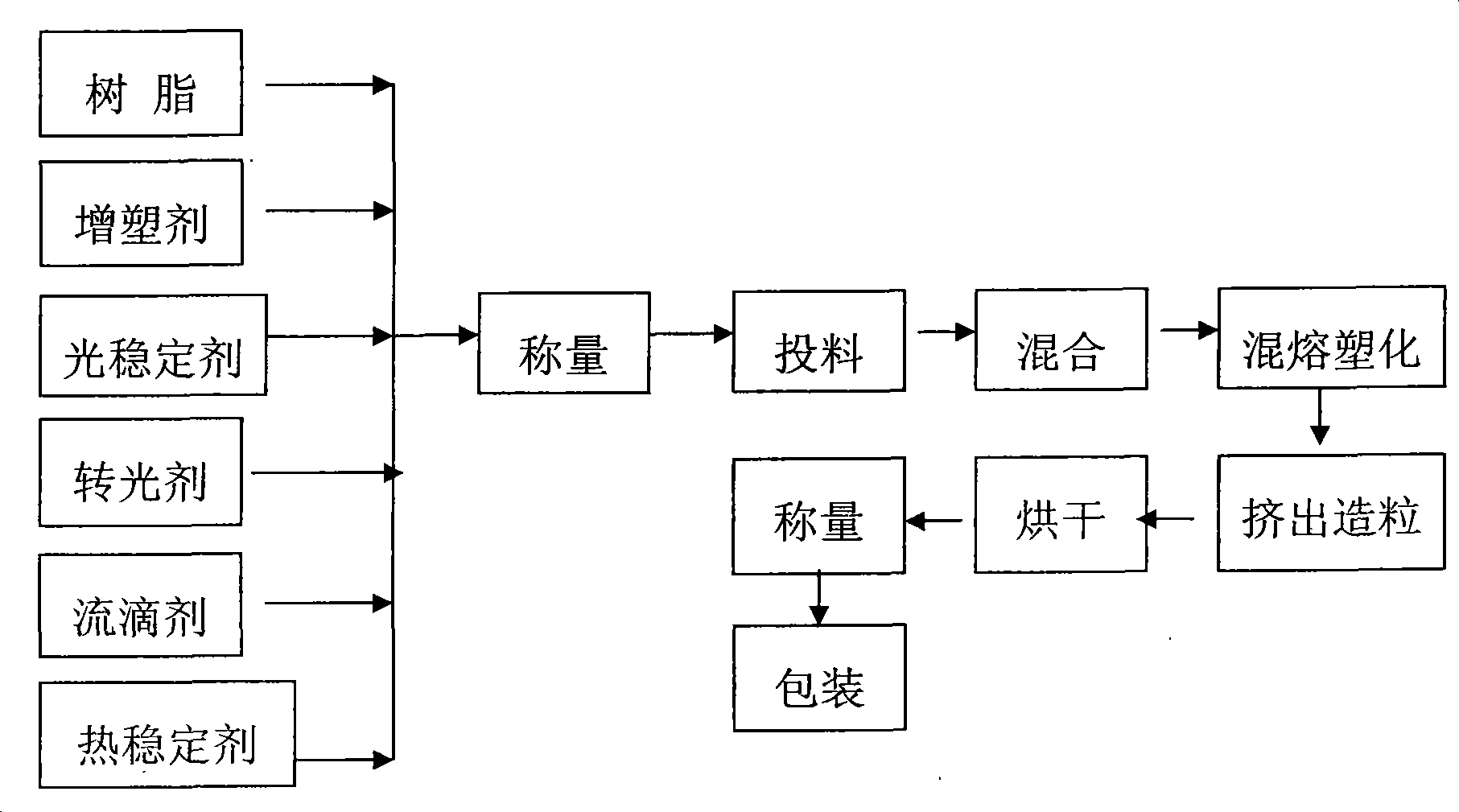

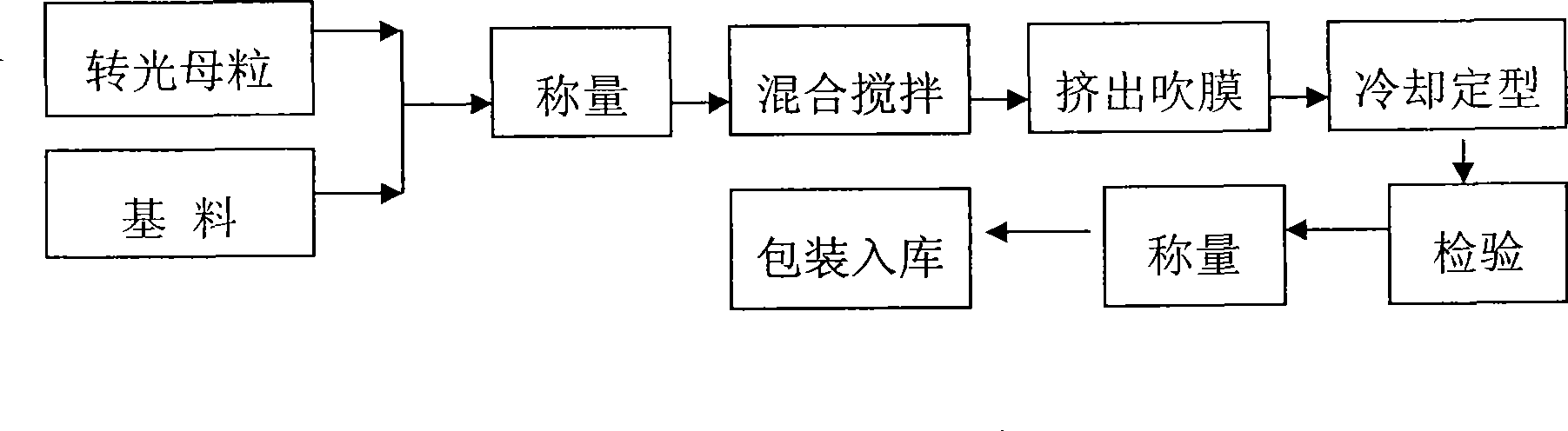

[0030] 1. Production of light conversion masterbatch

[0031] Get 50 parts of low-density polyethylene (PE), 50 parts of plasticizer dimethyl phthalate, light stabilizer take tricresyl phosphate, epoxidized soybean oil, octadecane in a weight ratio of 5:3:2 25 parts of zinc-based phosphate complexes, 20 parts of barium stearate and zinc stearate complexes that the heat stabilizer weight ratio is 1:1, and the dripping agent is 1:1 by weight ratio of sorbitol laurate, 15 parts of glyceryl stearate complex, 1 part of compound light-changing agent (blue light-changing agent M (L 1) n and red light conversion material A x B 1-x L 2 L 3 The weight ratio is 1:1), add plastic mixer, control the stirring speed, stir at high speed for 20-30 minutes, control the temperature at 140°C-150°C until the resin is in a plasticized state, discharge it, put it into the granulation extruder for granulation, Set the temperature of the extruder to 130°C. After the masterbatch is cooled, it is ...

Embodiment 2

[0035] 1. Production of light conversion masterbatch

[0036] Get 50 parts of vinyl chloride (PVC), 30 parts of plasticizer dimethyl phthalate, light stabilizer take tricresyl phosphate, epoxidized soybean oil, stearyl phosphoric acid in a weight ratio of 6:3:1 25 parts of zinc complexes, 16 parts of barium stearate and zinc stearate complexes with a weight ratio of 1:1 as heat stabilizer, and sorbitol palmitate and stearin with a weight ratio of 1:1 for dripping agent 15 parts of acid glyceride complex, 5 parts of compound light-changing agent (blue light-changing agent M (L 1 ) n and red light conversion material A x B 1-x L 2 L 3 The weight ratio is 1:30), add plastic mixer, control the stirring speed, stir at high speed for 20-30 minutes, control the temperature at 120°C-140°C until the resin is in a plasticized state, discharge it, put it into the granulation extruder for granulation, Set the temperature of the extruder at 120°C-130°C. After the masterbatch is coole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com