Water quality on-line detection method and system

A detection method and detection system technology, which are used in the preparation of test water, material inspection products, and test samples, can solve the problems of easy blockage of the outlet, high cost, easy blockage, etc., to avoid blockage, high reliability, and difficult blocking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

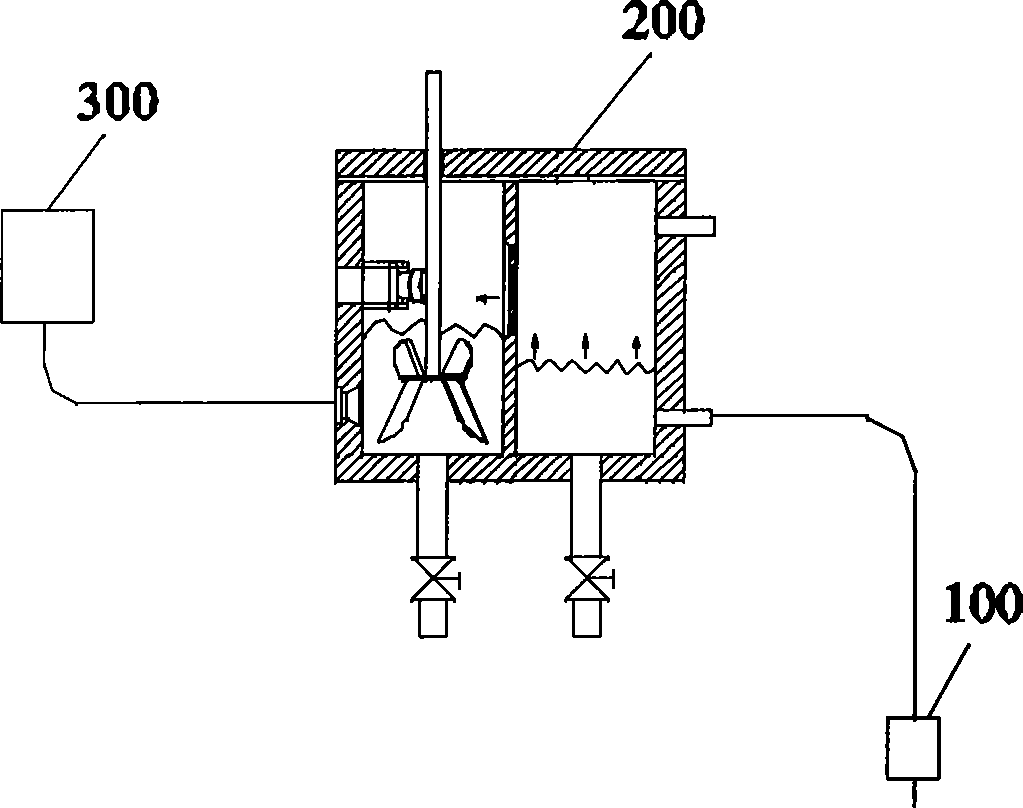

[0068] A water quality on-line detection system is used for measuring COD in water samples, comprising a sampling device, a pretreatment device, a detection pool and a detection device connected in sequence.

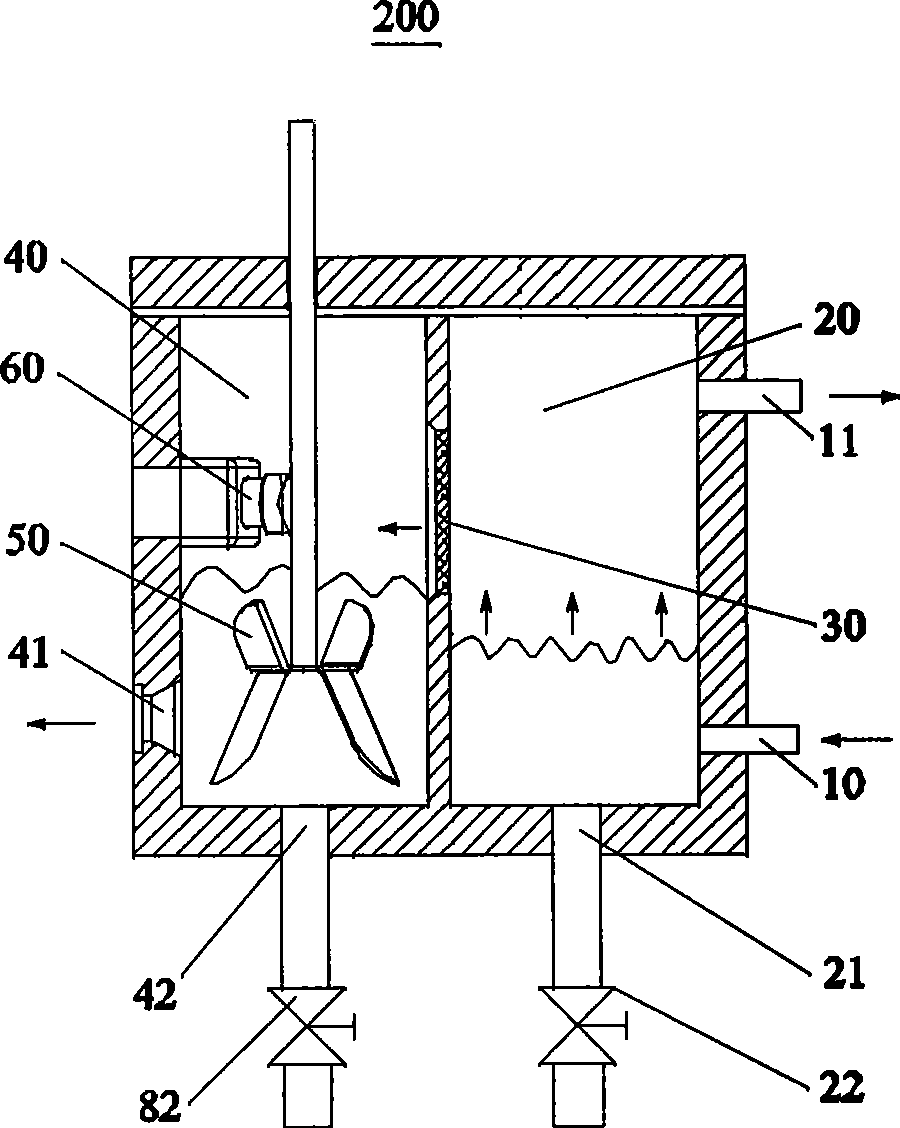

[0069] Such as image 3 As shown, the pretreatment device includes a water inlet pipe 10 connected to a sampling device, a filter screen 30 , a water storage chamber 40 , and a waste water chamber 20 . The filter screen 30 is arranged between the water storage chamber 40 and the waste water chamber 20, the water inlet pipe 10 is connected to the sampling device, and the angle a between the opening direction of the end of the water inlet pipe 10 and the filter screen 30 is 30°. A water intake 41 and a drain 42 are set on the water storage chamber 40 below the filter screen 30, the water intake 41 is connected to the downstream detection pool through a water intake pipe, the drain 42 is connected to a drain valve 82 through a drain pipe 81, and the water intake 41 is also ...

Embodiment 2

[0086] A water quality online detection system for measuring ammonia nitrogen in water samples, such as Figure 4 Shown, different from embodiment 1 is:

[0087] 1. Removed the homogenizing device.

[0088] 2. The angle a between the opening direction of the end of the water inlet pipe and the filter screen 30 is 8°.

[0089] 3. Rinse the filter with water steam instead of clean water.

[0090] This embodiment also discloses a water quality online detection method, which is different from Embodiment 1 in that:

[0091] 1. There is no homogenization step for stirring the water sample to be tested, and there is no stirring and cleaning step for stirring the water sample in the water storage chamber after the measurement is completed.

[0092] 2. The angle a between the speed direction of the water sample and the filter screen 30 when it passes through the filter screen is 8°.

Embodiment 3

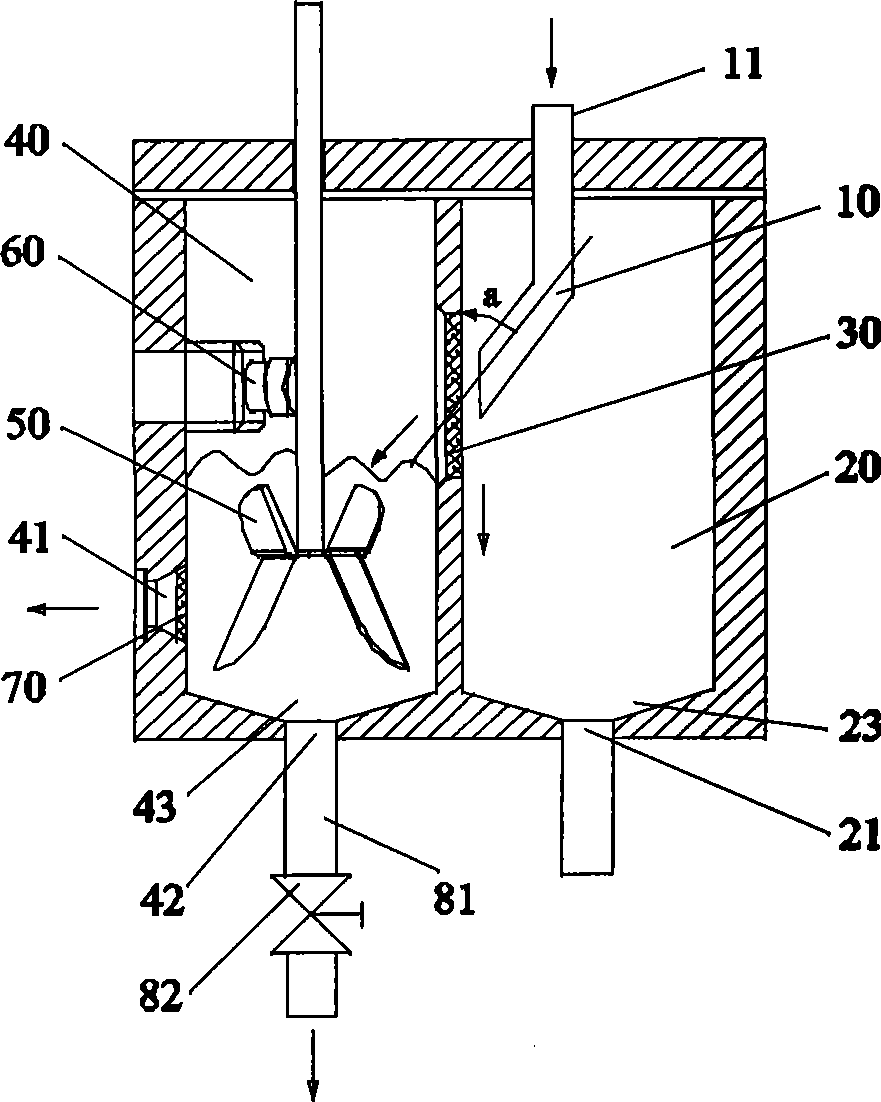

[0094] A water quality online detection system for measuring COD of water samples, such as Image 6 Shown, different from embodiment 1 is:

[0095] 1. Remove the drain valve 82.

[0096] 2. The water storage chamber 40 and the waste water chamber 20 are made of transparent glass.

[0097] 3. The angle a between the opening direction of the end of the water inlet pipe 10 and the filter screen 30 is 20°.

[0098] This embodiment also discloses a method for online detection of water quality, measuring the COD of the water sample, such as Figure 9 shown, including the following steps:

[0099] a. Sampling steps

[0100] The water pump in the sampling device is turned on to obtain the water sample under the measured environment, and transport it to the pretreatment device through the water inlet pipe 10. The angle a between the velocity direction of the water sample and the filter screen 30 is 20°.

[0101] b. Preprocessing steps

[0102] On the one hand, some water samples ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com