Method and apparatus for improving primary air breeze gas flow temperature of W-shaped flame boiler

A technology of air pulverized coal and flame, which is applied in the field of improving the primary air auxiliary hot air of W-type flame boilers, which can solve the problems of stable combustion and poor ignition ability, and achieve the effects of easy ignition, stable combustion and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

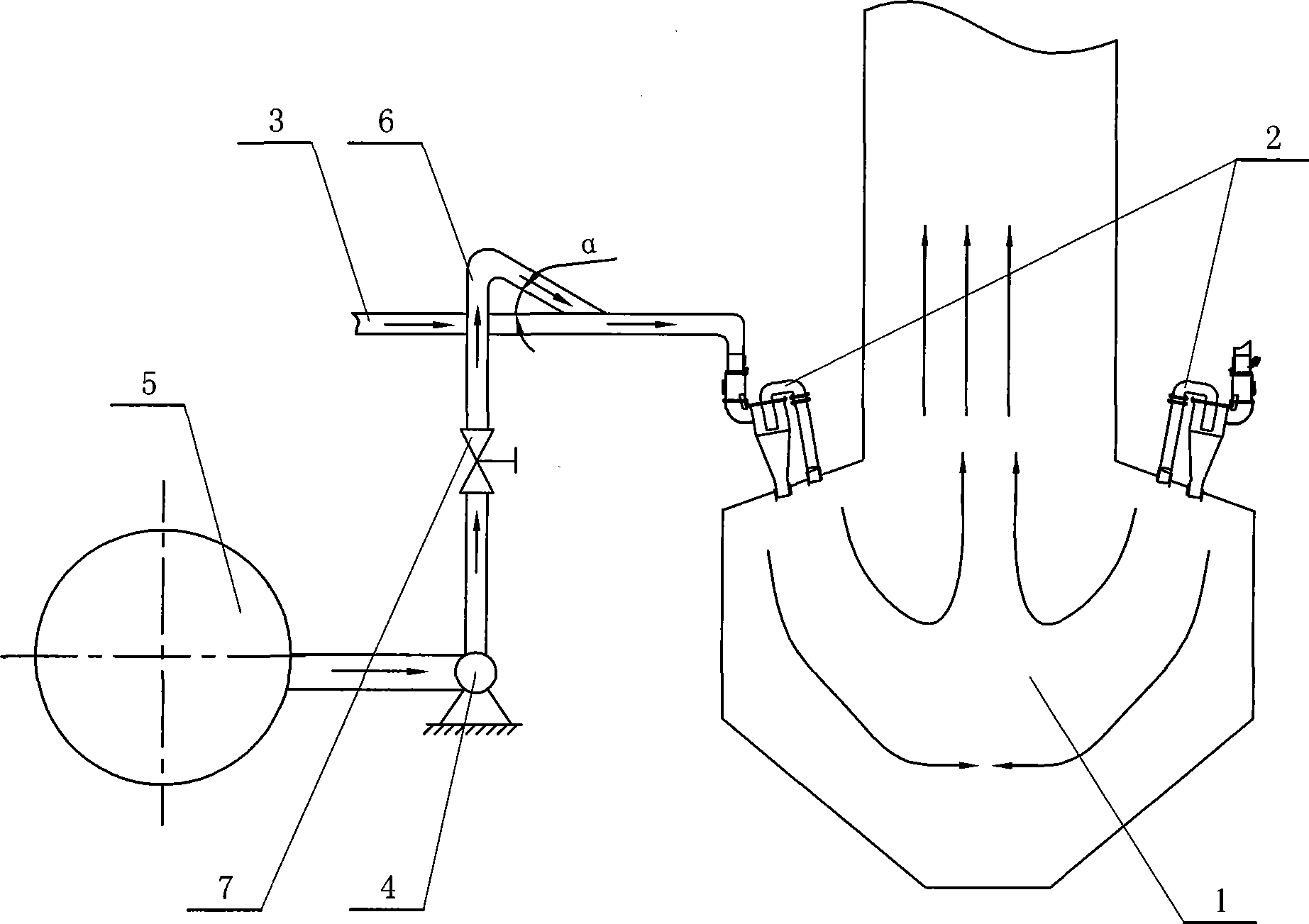

[0008] Specific implementation mode one: combine figure 1 Describe this embodiment, the method of this embodiment is finished like this: auxiliary air is drawn out by hot air pipe 5, and auxiliary air temperature is 320 ℃~370 ℃ (the air temperature is the same as the air temperature of secondary air), and auxiliary air passes through The fan 4 and the auxiliary air pipe 6 are connected to the primary air pipe 3 before the air inlet port of the burner 2, and are mixed with the primary air with a temperature of 100°C-110°C and a wind speed of 22.0-23.0m / s. The auxiliary air volume entering the primary air duct 3 is regulated by the valve 7 arranged on the auxiliary air duct 6, and the included angle α between the direction of the auxiliary air entering the primary air duct 3 and the flow direction of the primary air pulverized coal is 25°~35°, the auxiliary air volume leading into the primary air duct 3 accounts for 19%~21% of the total primary air volume, the temperature of the...

specific Embodiment approach 2

[0009] Specific implementation mode two: combination figure 1 Describe this embodiment, the difference between this embodiment and specific embodiment 1 is: the auxiliary air in this embodiment is drawn out from the hot air pipe 5, the temperature of the auxiliary air is 320°C, and the auxiliary air passes through the induced draft fan 4 and the auxiliary air pipe 6 It is passed into the primary air duct 3 before the air inlet port of the burner 2, and mixed with the primary air with a wind temperature of 105°C and a wind speed of 22.4m / s. The auxiliary air volume passed into the primary air duct 3 is set by setting The valve 7 on the auxiliary air duct 6 is adjusted so that the included angle α between the direction of the auxiliary air flowing into the primary air duct 3 and the flow direction of the primary air pulverized coal is 30°, which is relatively small to prevent the occurrence of gas seal , to ensure the normal delivery of the primary air pulverized coal, the tempe...

specific Embodiment approach 3

[0010] Specific implementation mode three: combination figure 1 Describe this embodiment, the difference between this embodiment and specific embodiment 1 or 2 is: the auxiliary air volume that passes into the primary air duct 3 of this embodiment accounts for 20% of the total primary air volume, effectively realizing the pulverized coal air flow caught fire in time. But at the same time, it should be noted that the auxiliary air cannot be increased blindly. When too much auxiliary air is fed in, the primary wind speed will be very high. If the primary wind speed is too high, the resistance in the primary air pipe will increase, which will affect the output of the coal mill. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com