Method and apparatus for hydraulic jet side drilling for radial branching borehole

A technology of hydraulic jetting and branch wells, which is applied in liquid/gas jet drilling, drilling equipment and methods, drilling equipment, etc., and can solve the problems of low efficiency of window opening tools, high cement strength requirements, and slow rock breaking speed of drill bits, etc. , to achieve the effect of high-efficiency increase in production recovery, reduce labor intensity, and avoid downhole accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

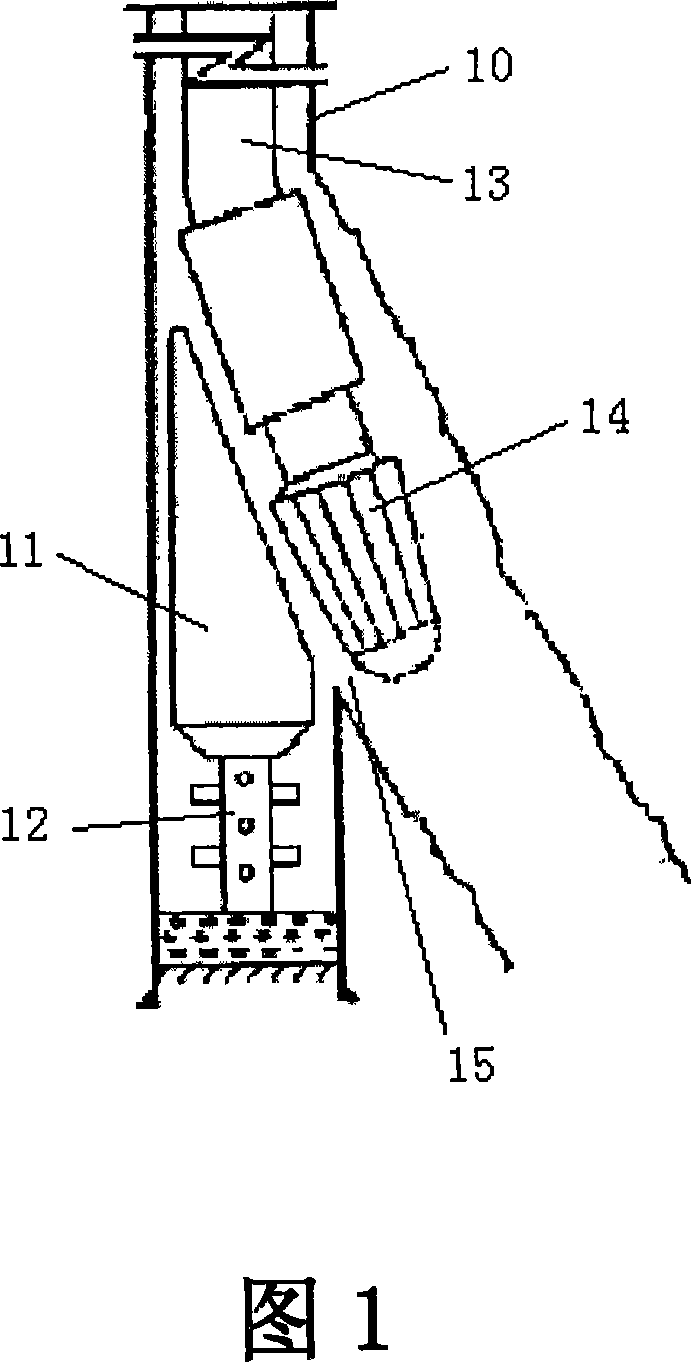

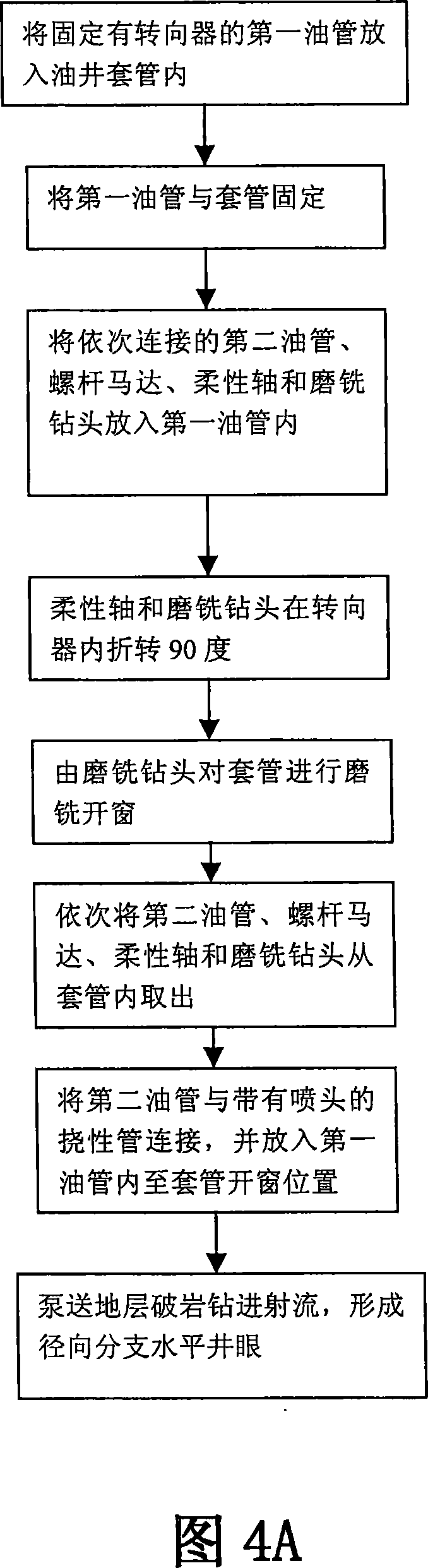

[0052] Please refer to FIG. 4A , which is a flow chart of the first technical solution of the hydrojet sidetracking radially branched wellbore method of the present invention. The method for sidetracking the radially branched wellbore of the scheme in the present invention comprises the following steps:

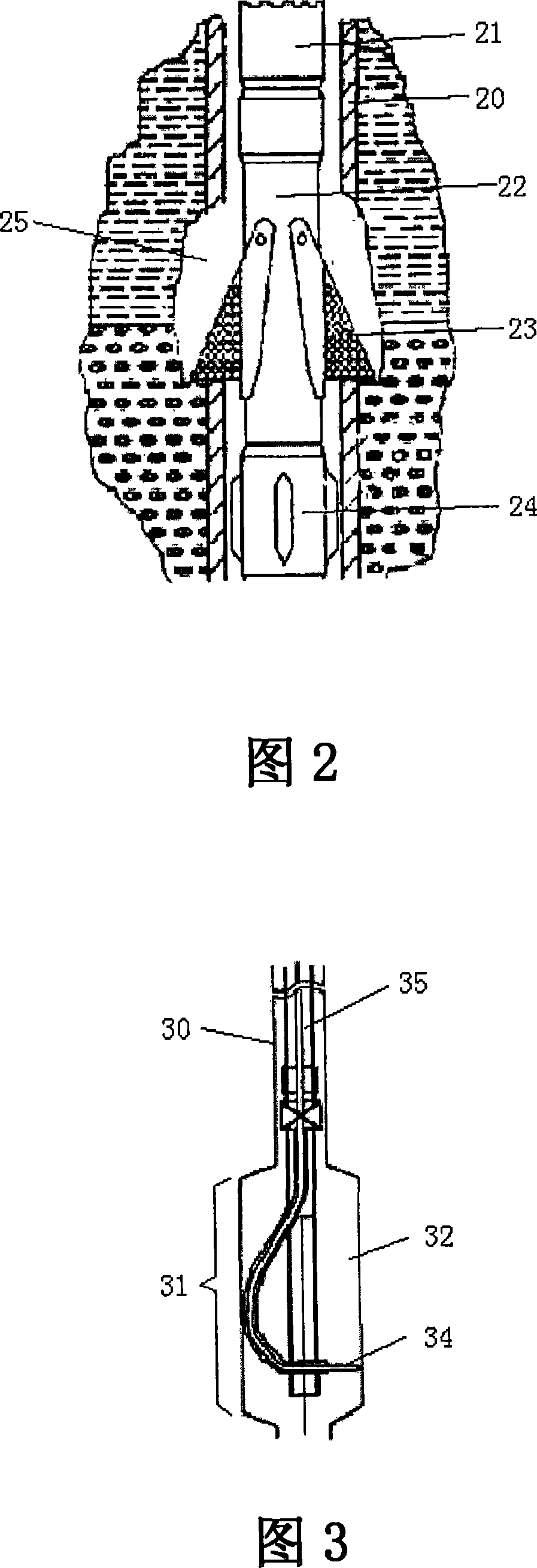

[0053] (1) Put the first oil pipe 40 with the diverter 44 fixed at the end into the oil well casing 50, and drop it to a specified depth; wherein, the outer dimension of the diverter 44 is smaller than the inner diameter of the casing 50, by The through passage provided in the diverter 44 connects the top and the side wall of the diverter; please refer to FIG. 5 for cooperation;

[0054] (2) Fix the first oil pipe 40 and the casing 50 by the oil pipe anchor 41 arranged on the first oil pipe 40, so that the diverter 44 is fixed at the specified depth position;

[0055] (3) Put the second oil pipe (not shown in the figure) whose outer diameter is smaller than the inner diamete...

Embodiment approach 2

[0068]Please refer to FIG. 4B , which is a flow chart of the second technical solution of the hydrojet sidetracking radially branched wellbore method of the present invention. The method for sidetracking the radially branched wellbore of the scheme in the present invention comprises the following steps:

[0069] (1) Put the first oil pipe 40 with the diverter 44 fixed at the end into the oil well casing 50, and drop it to a specified depth; wherein, the outer dimension of the diverter 44 is smaller than the inner diameter of the casing 50, by The through passage arranged in the diverter 44 communicates with the top and the side wall of the diverter;

[0070] (2) Fix the first oil pipe 40 and the casing 50 by the oil pipe anchor 41 arranged on the first oil pipe 40, so that the diverter 44 is fixed at the specified depth position;

[0071] (3) Put the second oil pipe whose outer diameter is smaller than the inner diameter of the first oil pipe 40 into the first oil pipe, and a...

Embodiment approach 3

[0082] Please refer to FIG. 4C , which is a flow chart of the third technical solution of the hydrojet sidetracking radially branched wellbore method of the present invention. The method for sidetracking the radially branched wellbore of the scheme in the present invention comprises the following steps:

[0083] (1) Put the first oil pipe 40 with the diverter 44 fixed at the end into the oil well casing 50, and drop it to a specified depth; wherein, the outer dimension of the diverter is less than or equal to the inner diameter of the casing, by setting The through channel in the diverter 44 communicates with the top and side walls of the diverter;

[0084] (2) Fix the first oil pipe 40 and the casing 50 by the oil pipe anchor 41 arranged on the first oil pipe 40, so that the diverter 44 is fixed at the specified depth position;

[0085] (3) Put the second oil pipe 61 whose outer diameter is smaller than the inner diameter of the first oil pipe 40 into the first oil pipe, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com