Abrasive machining method for cuneiform aspheric surface

A technology of grinding processing and processing methods, applied in metal processing equipment, grinding machine parts, grinding/polishing equipment, etc., can solve problems such as no clear understanding of the influence of process and processing accuracy, and few wedge-shaped aspherical mirrors. , to achieve the effect of stable machining accuracy, high precision and high shape accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The following embodiments will further illustrate the present invention in conjunction with the accompanying drawings.

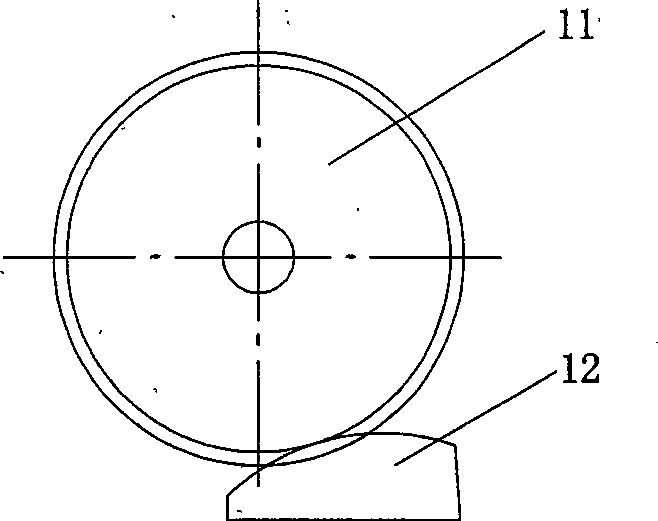

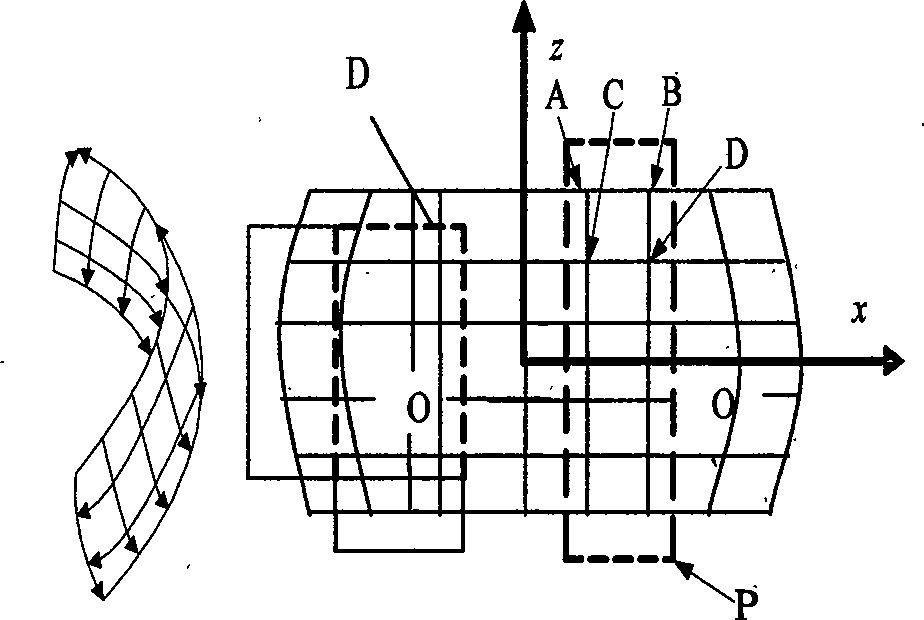

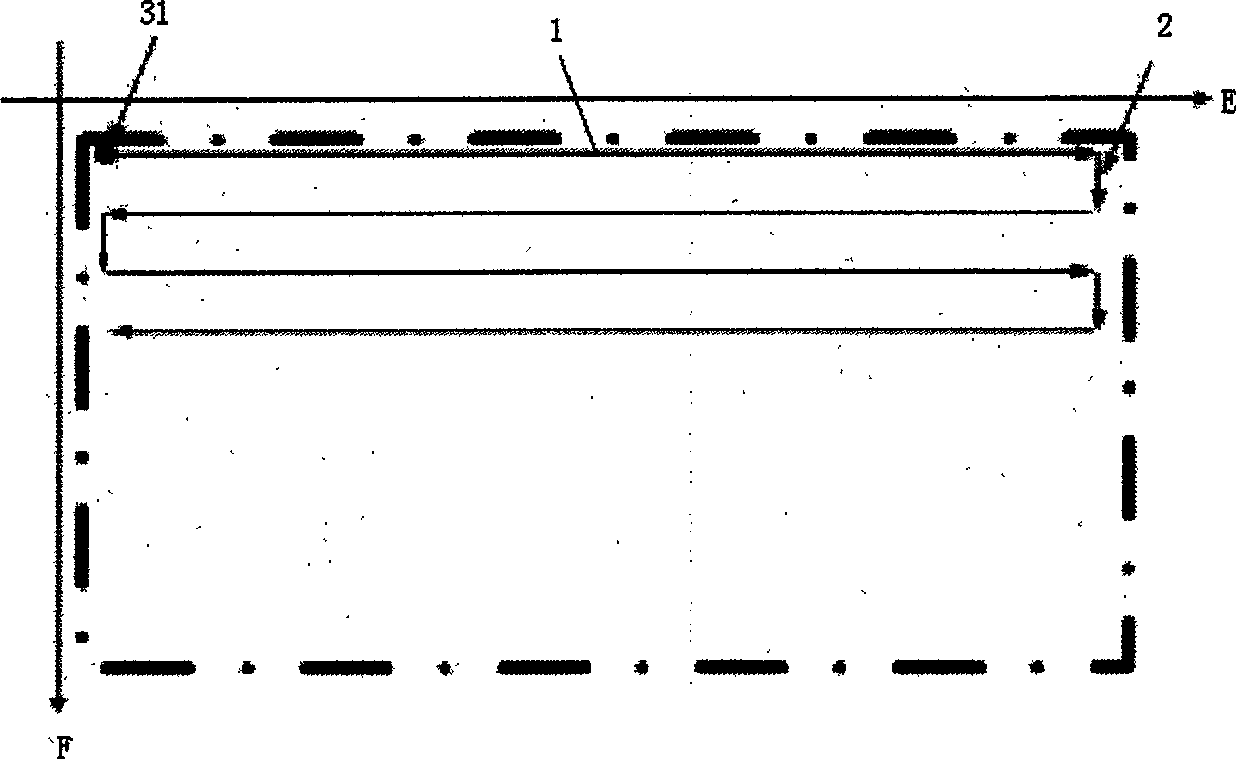

[0042] The embodiments of the present invention provide a novel grinding method for processing generalized wedge-shaped aspheric surfaces on the existing three-linear-axis grinding machine. The device adopted in the present invention is generally provided with work platform, sensor, diamond grinding wheel (preferably diamond arc grinding wheel), A / D converter, industrial computer, numerical control device and workpiece shaft, and workpiece is placed on the work platform, and sensor place The collected signal is converted into a digital signal through the A / D converter and sent to the industrial computer, and the output signal of the industrial computer directly controls the movement of the working platform through the numerical control device. The diamond grinding wheel is installed on the workpiece shaft, and the workpiece shaft is set on the working...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com