Bracket structure of auxiliary vertical roll

A support structure and vertical roller technology, which is applied in the field of support structure of auxiliary vertical rollers, can solve problems such as poor structural rigidity, easy jamming, and affecting the service life of vertical rollers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

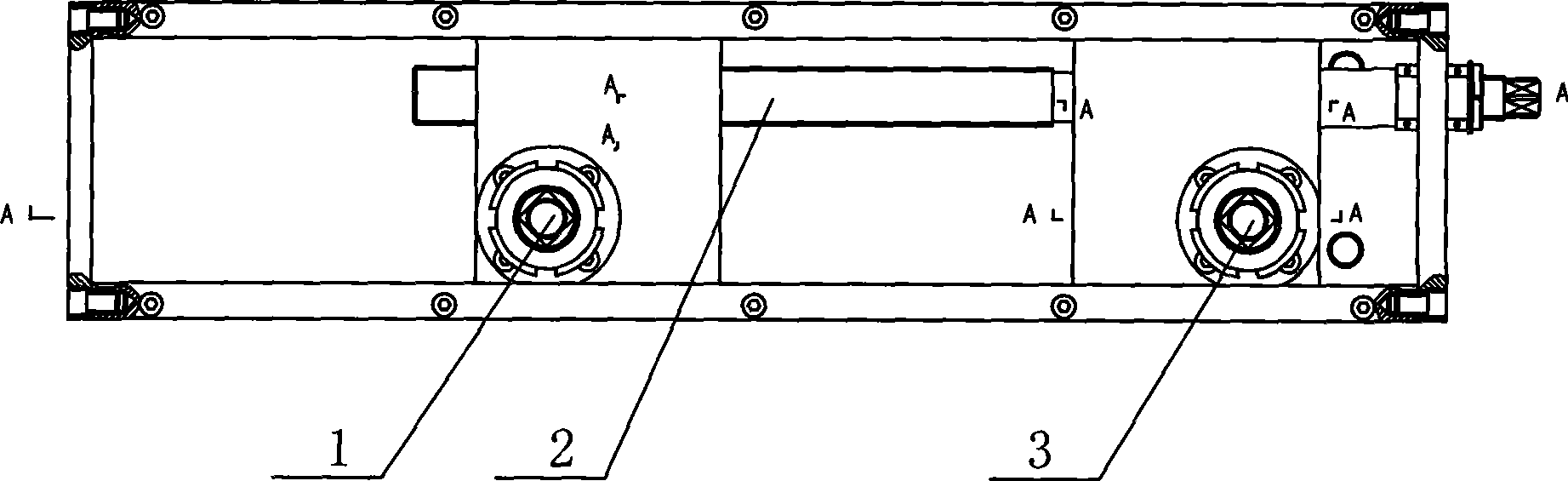

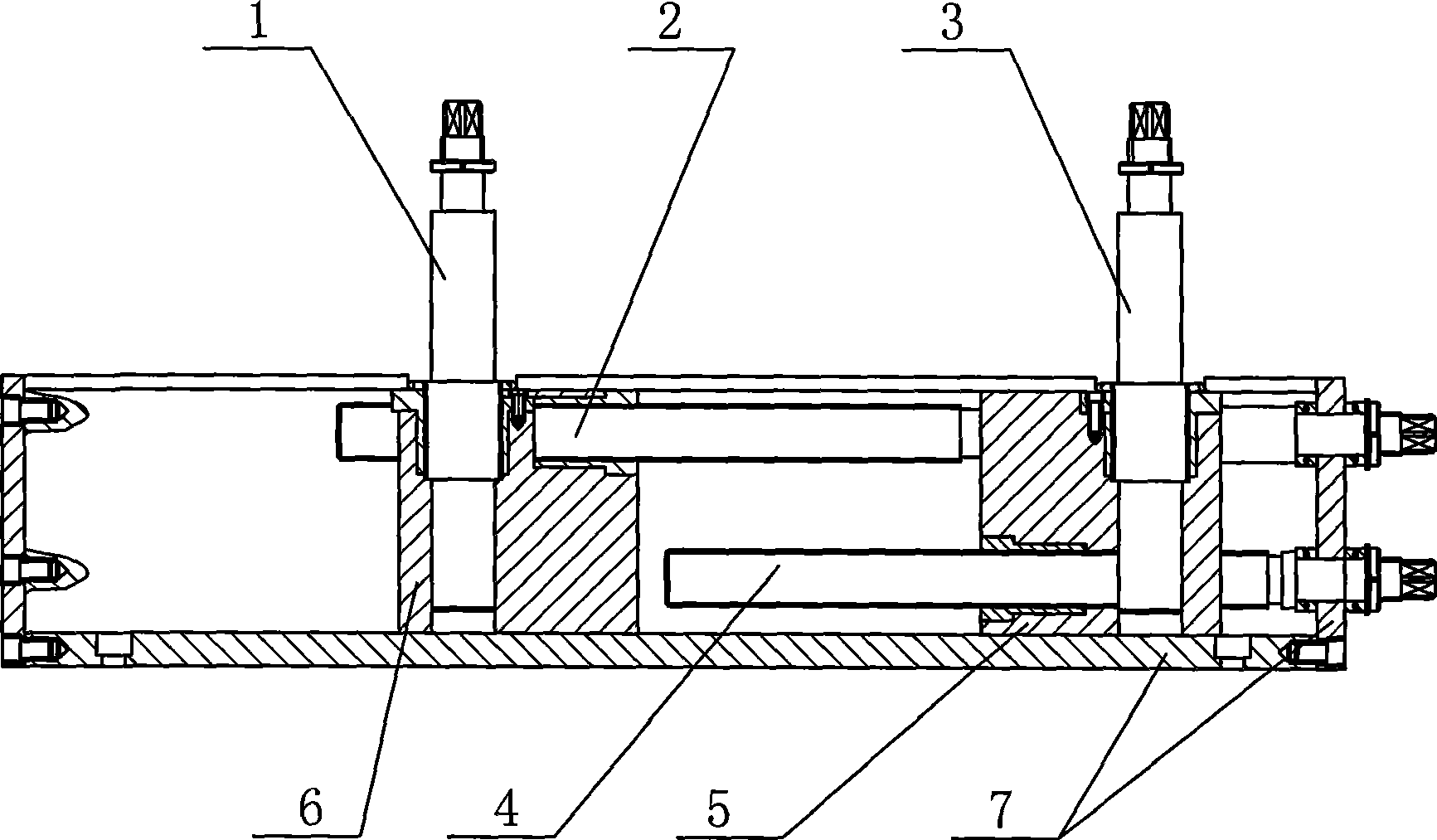

[0008] See figure 1 , figure 2 , the present invention comprises two vertical rollers 1,3, and vertical rollers 1,3 are respectively installed on slide block 6,5, and screw mandrel 2,4 is respectively installed in slide block 6,5, and the wire rod that is positioned at its interior of the slide block of outside The rod goes through the slider on the inside, figure 2 In the middle, the screw rod 2 passes through the slider 5, the screw rods 2 and 4 are respectively connected with the ends of the rack box 7 with bolts, the sliders 6 and 5 are mounted on the track, and the track is set at the bottom of the rack box 7 , the two sides of slide block 6,5 are slidably matched with the two sides of frame box body 7.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com