Compound apparatus for fumigant

A fumigant and steel cylinder technology, applied in the field of fumigation, can solve the problems of insufficient mixing, component deviation of compound fumigant, difficulty in research and development of compound fumigant, etc., and achieve the effect of convenient sampling and convenient research.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

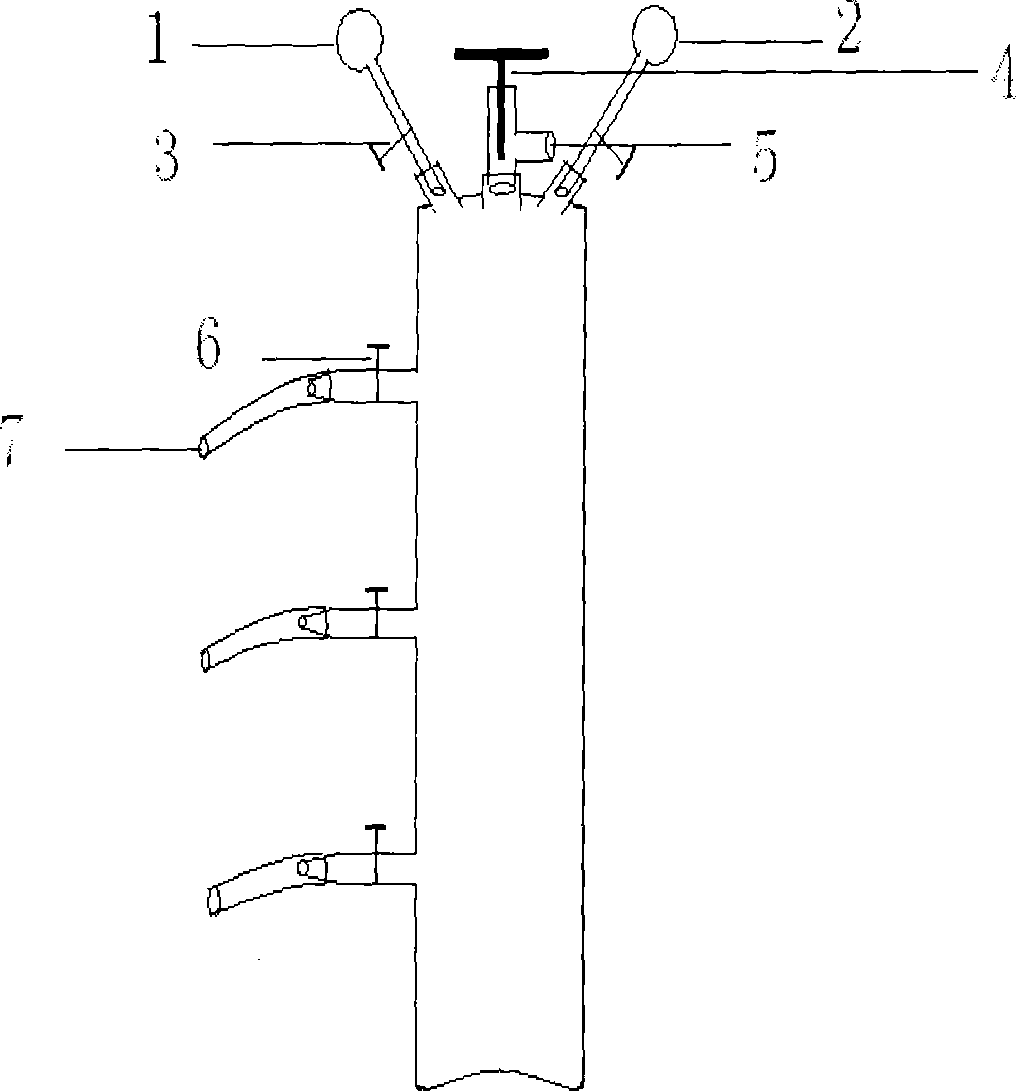

[0015] See figure 1 . An air inlet 5 is drilled in the center of the top of a long columnar steel cylinder made of stainless steel that can withstand 2.0Mpa, and an air inlet valve 4 is welded and installed at the air inlet, and holes are drilled and welded on both sides of the air inlet valve A vacuum gauge 1 and a pressure gauge 2 are installed, and needle valves 3 are respectively provided on the pipelines connecting the vacuum gauge head of the vacuum gauge and the pressure gauge head of the pressure gauge to the steel cylinder; Needle valves 6 are installed by perforation welding, and latex tubes 7 are further connected to the gas outlets of the three needle valves on the cylinder body, which are respectively used as sampling ports for the compound fumigant.

[0016] Utilize the compounding device of fumigant of the present invention to carry out the compounding process of fumigant: open the needle valve 3 of vacuum meter 1, vacuumize the whole device to a certain degree...

Embodiment 2

[0018] The structure of the device is the same as in Example 1, except that the 3 needle valves installed at the middle, upper and lower parts of the steel cylinder body are respectively located in the middle of the steel cylinder body, the middle part of the steel cylinder body and the top of the steel cylinder body, The middle part between the middle of the cylinder body and the bottom of the cylinder body.

[0019] Using this device can better determine the percentage content of different components compounded into the fumigant in the steel cylinder in the liquid phase and gas phase and the uniformity of mixing up and down in the cylinder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com