Method of error correction

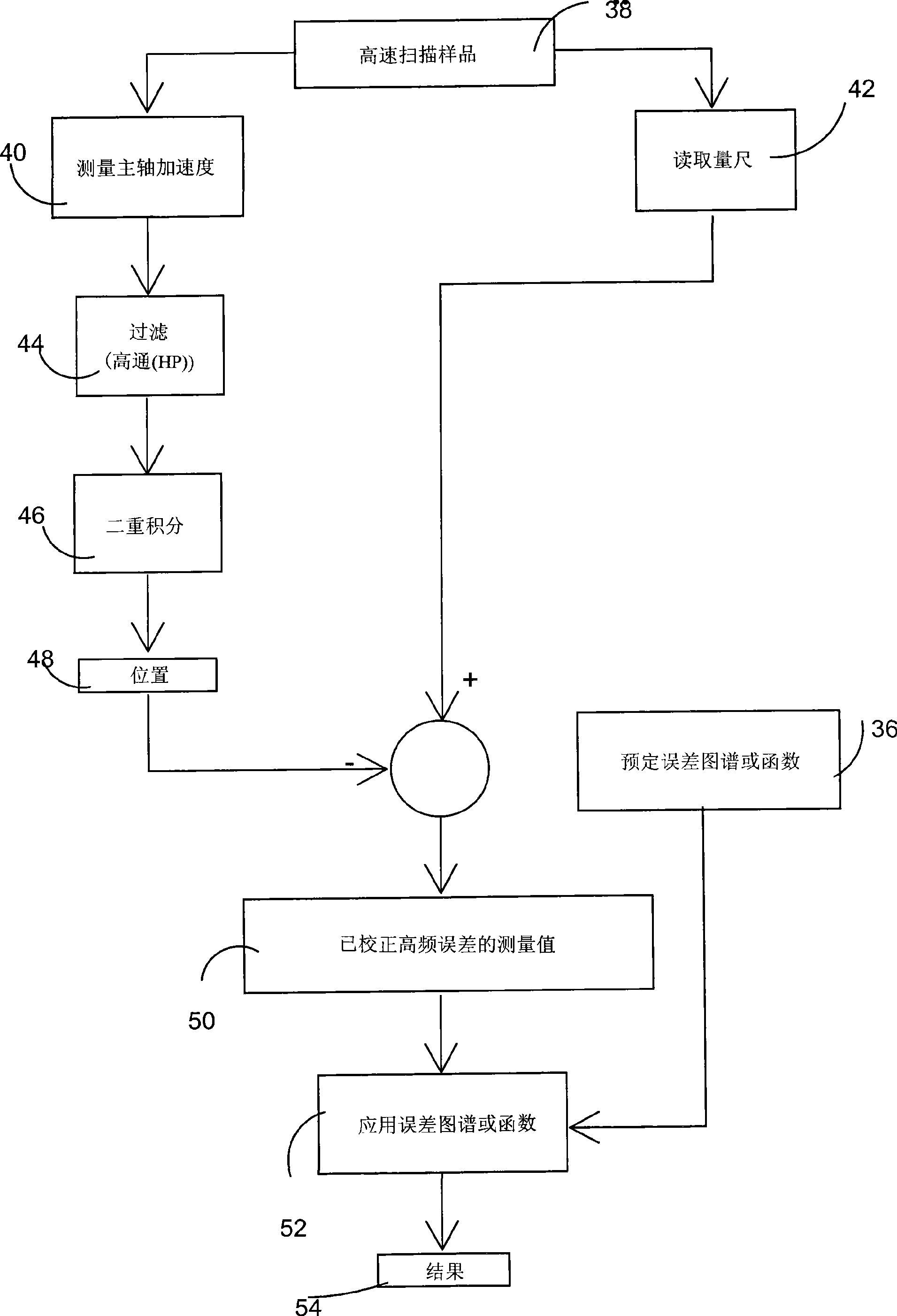

An error correction and error technology, which is applied in the field of coordinate positioning equipment to measure workpieces, can solve problems such as accelerometer drift and noise, unreliable calibration, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

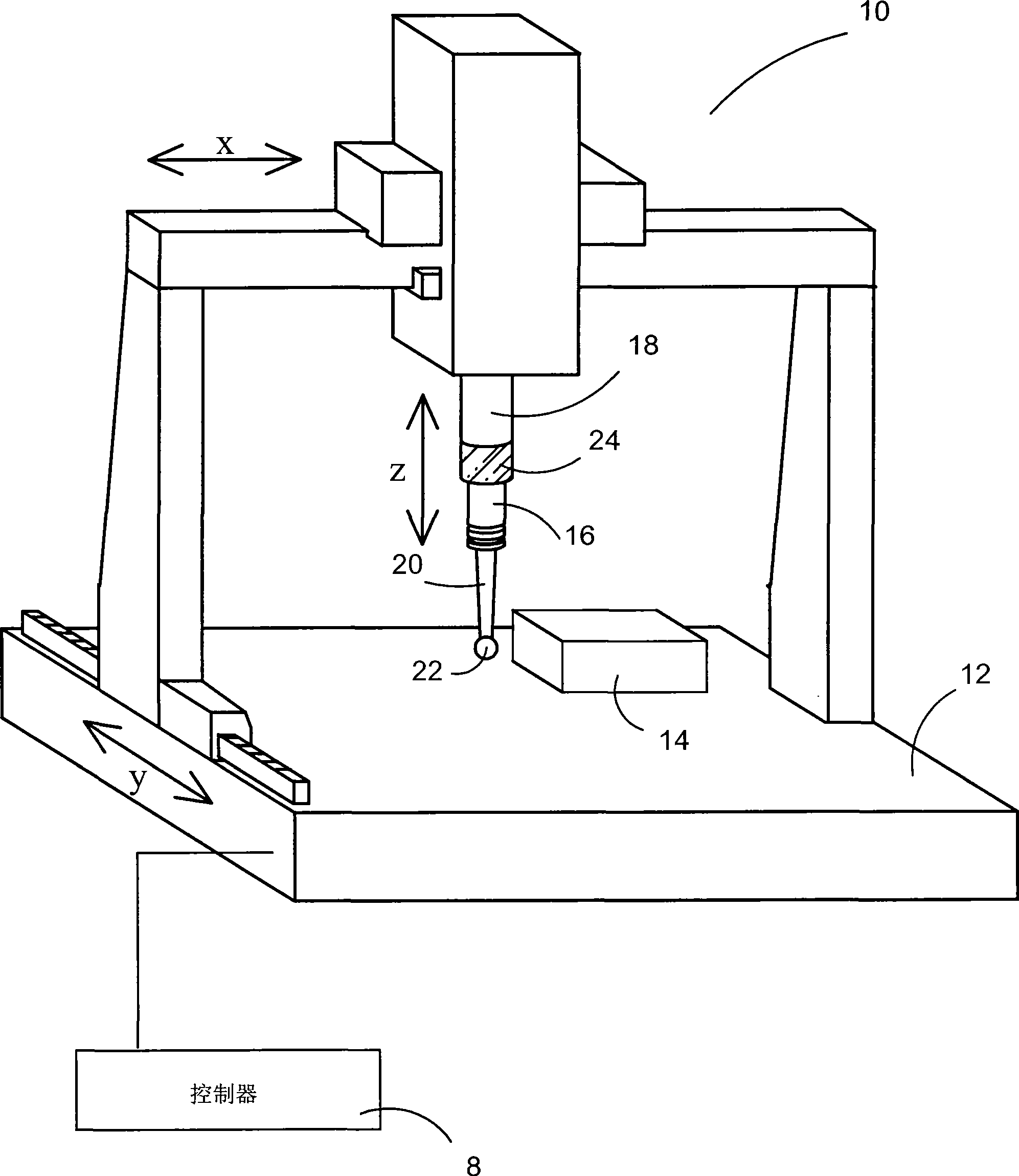

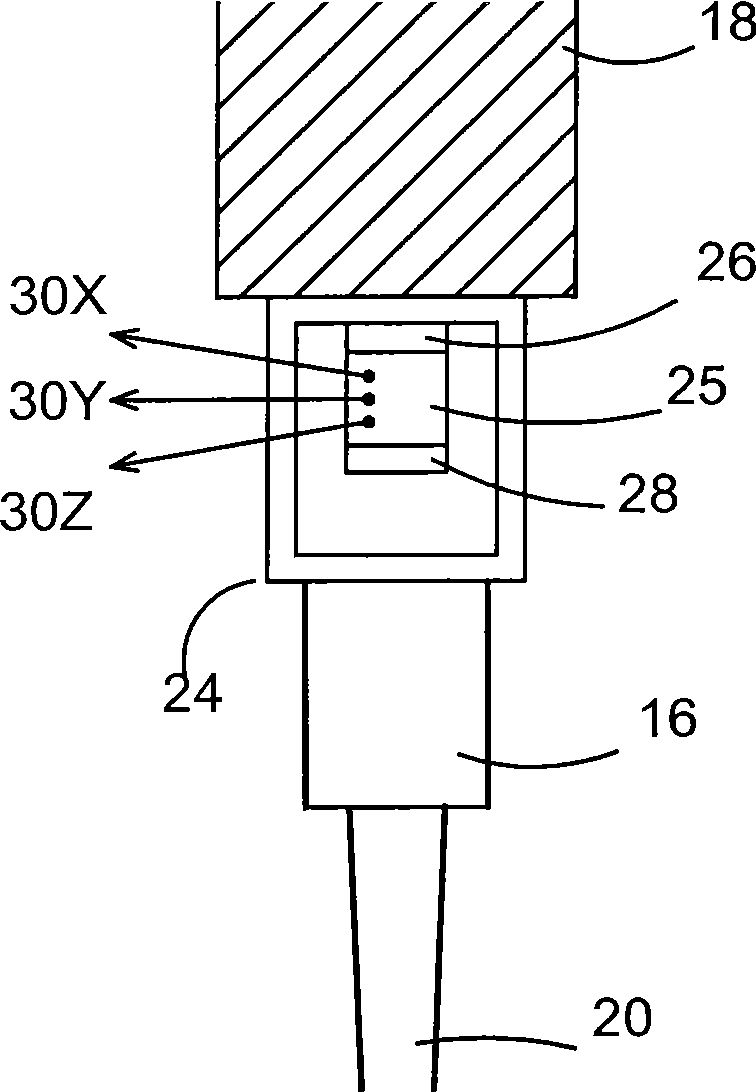

[0060] figure 1 The illustrated coordinate measuring machine (CMM) 10 includes a table 12 on which a workpiece 14 to be measured is placed. This is preferably done by robotic means (not shown) which places a series of substantially identical workpieces from the production line in at least nominally the same position and orientation on the table. An analog probe 16 having a deflectable stylus 20 with a workpiece contact tip 22 is mounted on the main shaft 18 of the instrument, although other types of probes (including contact trigger probes) may also be used. The spindle and probe are moved together in the x, y and x directions by computer-controlled x, y and z drives. The x, y and z scales (including counters for the output scale) show the instantaneous coordinates of the three-dimensional position of the spindle 18 on which the probe 16 is mounted. The signal from the probe 16 representing the deflection of the probe stylus 20 is combined with the CMM's x, y, z scale readin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com