Marine partition module

A technology for ships and cabins, which is applied in the field of cabin modules for ships, which can solve problems such as increased manufacturing costs of cabin modules, difficulties in cabin modules, and heavy galley modules, so as to achieve efficient hull construction and assembly construction, reduce costs, and reduce weight. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

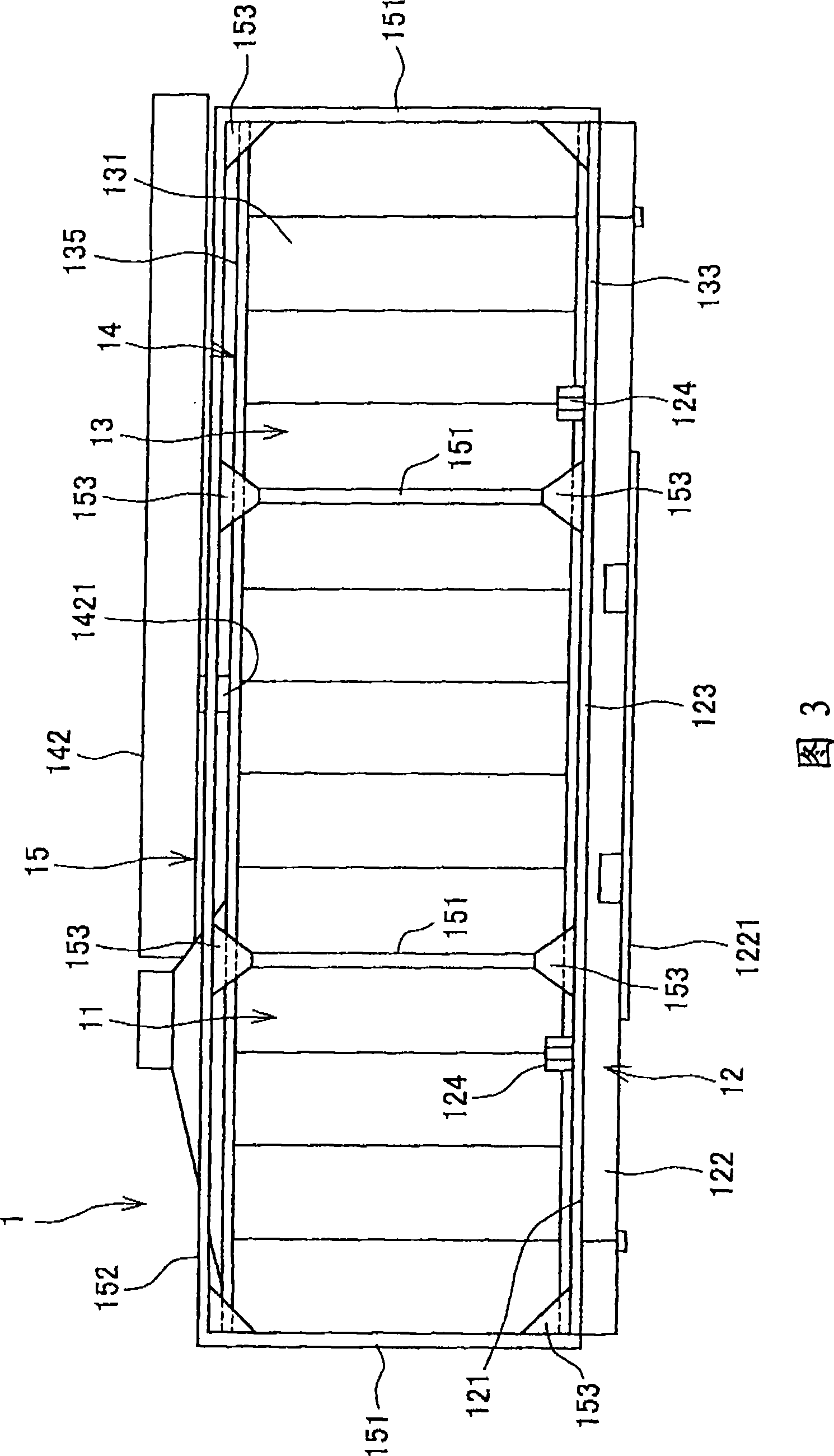

[0063] Preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings. In addition, in this specification and drawings, the same code|symbol is attached|subjected to the component which has substantially the same function, and repeated description is abbreviate|omitted.

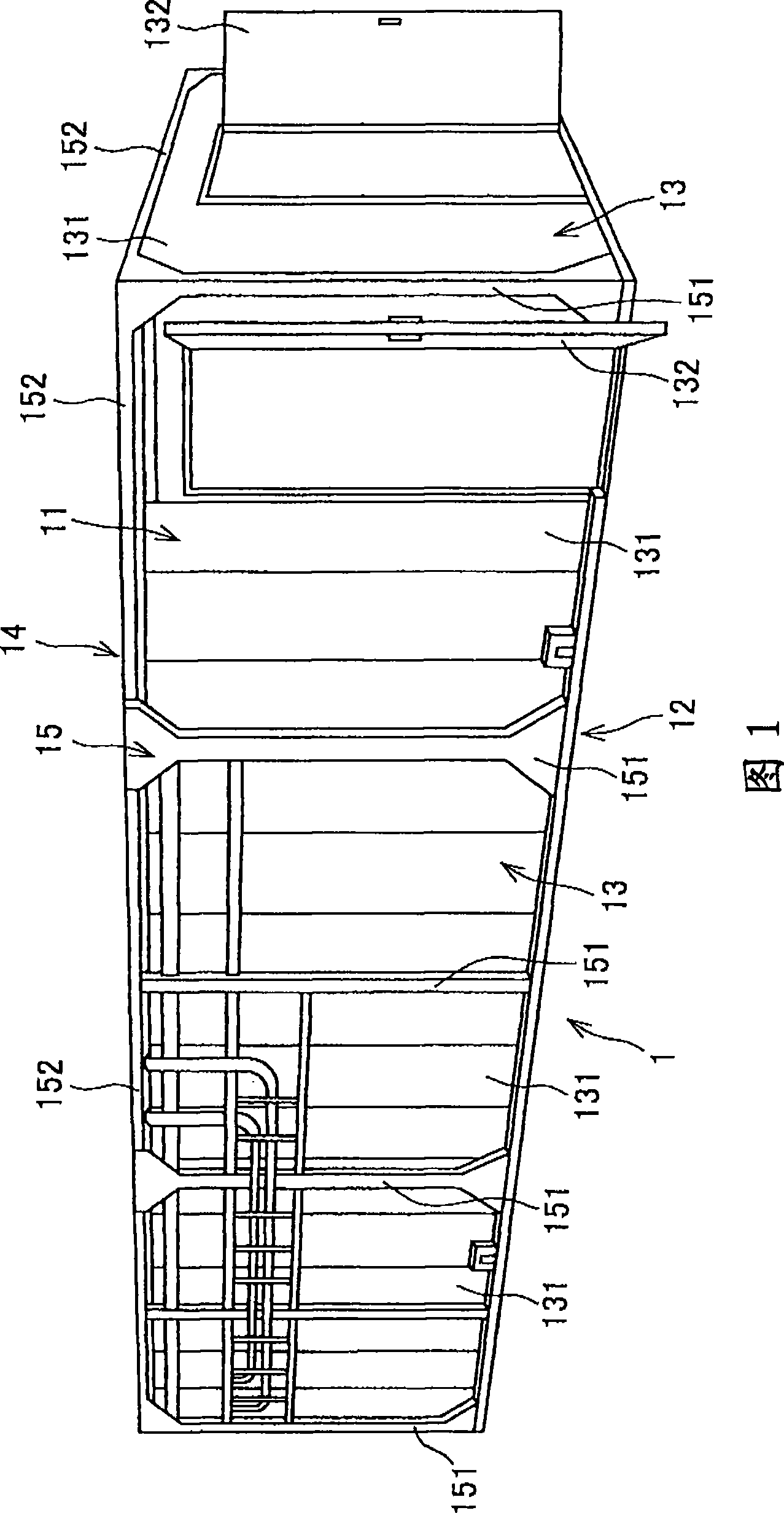

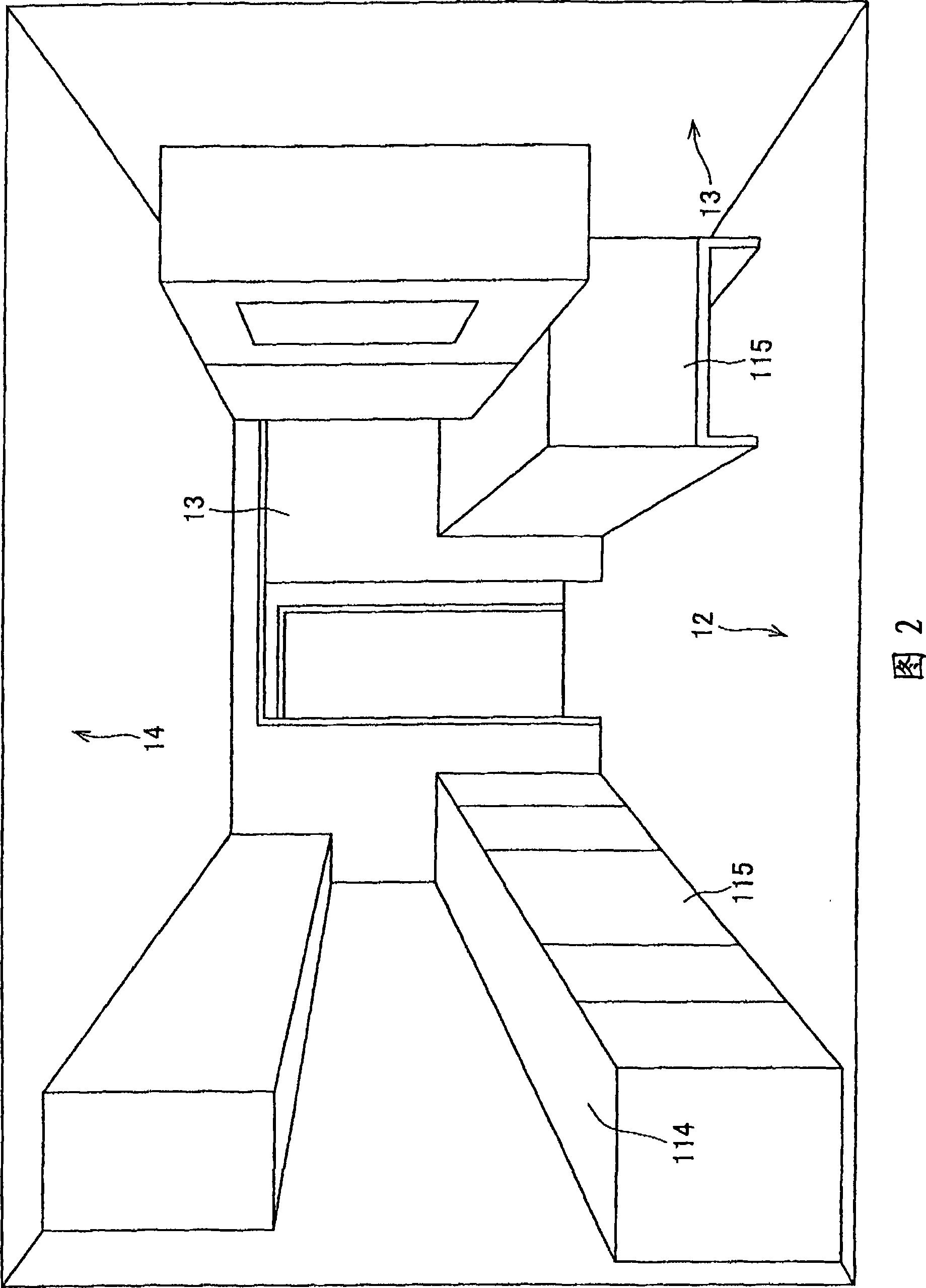

[0064] FIG. 1 is a perspective view showing the appearance of a cabin module 1 according to one embodiment of the present invention. As shown in FIG. 1 , the cabin module 1 has an appearance of a substantially rectangular parallelepiped. Doors 132 are provided on the front and side surfaces of the cabin module 1, and a closed predetermined space (unit cabin 11) is provided inside.

[0065] After the cabin module 1 is constructed outside the hull, it is moved into the hull by a crane or the like, and fixed to the hull. The space provided in the interior of the cabin module 1 is used as a pantry of the hull, a cabin for crew or passengers, a wheelh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com