Probe column, wafer testing seat and wafer testing system

A wafer test and probe technology, applied in the field of probe towers, can solve problems such as easy breakage of needles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 5 example

[0053] Please refer to Figure 8 , which is a fifth embodiment provided according to the present invention, is a wafer testing method. This test method consists of the following steps:

[0054] (1) Provide a wafer 5 to be tested (step 51).

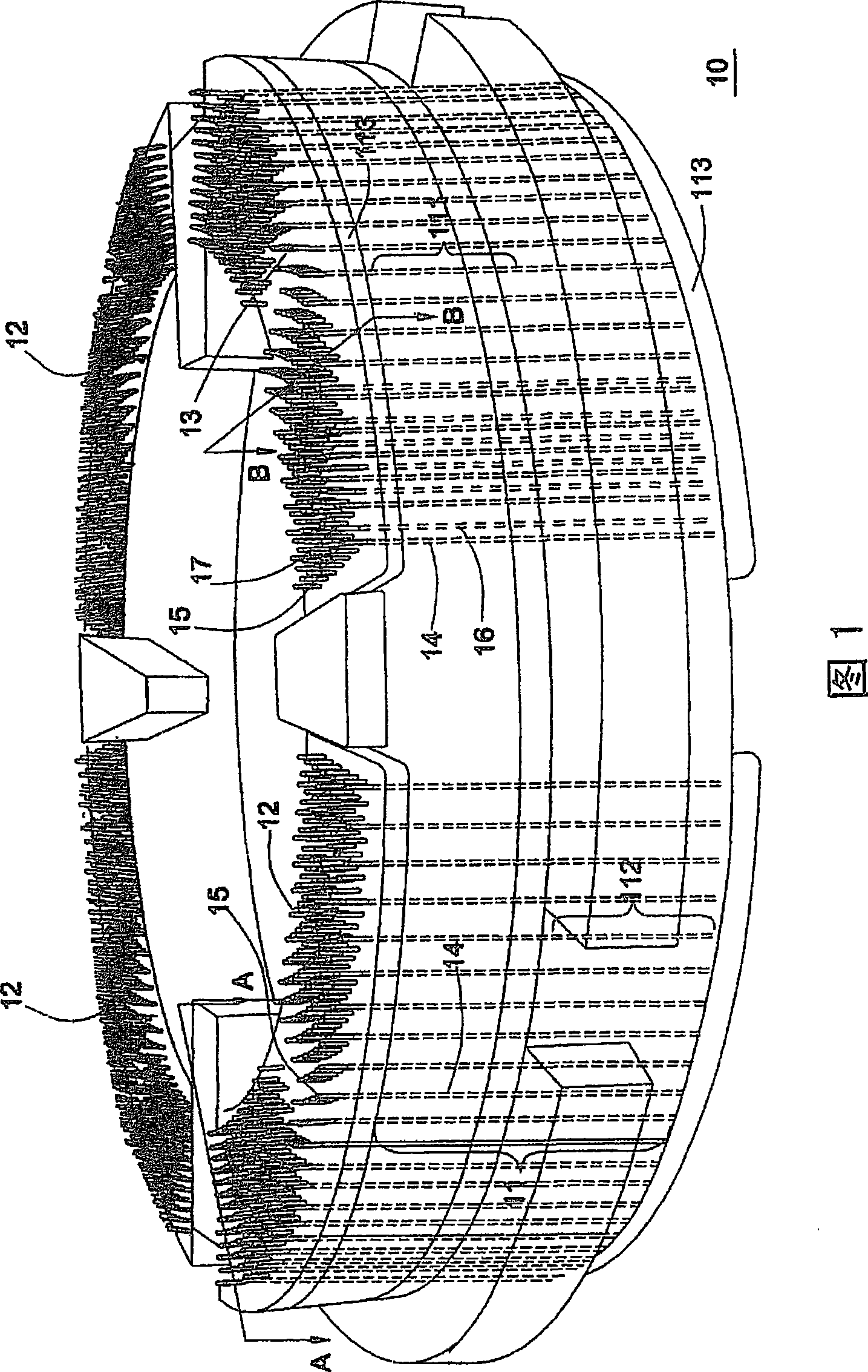

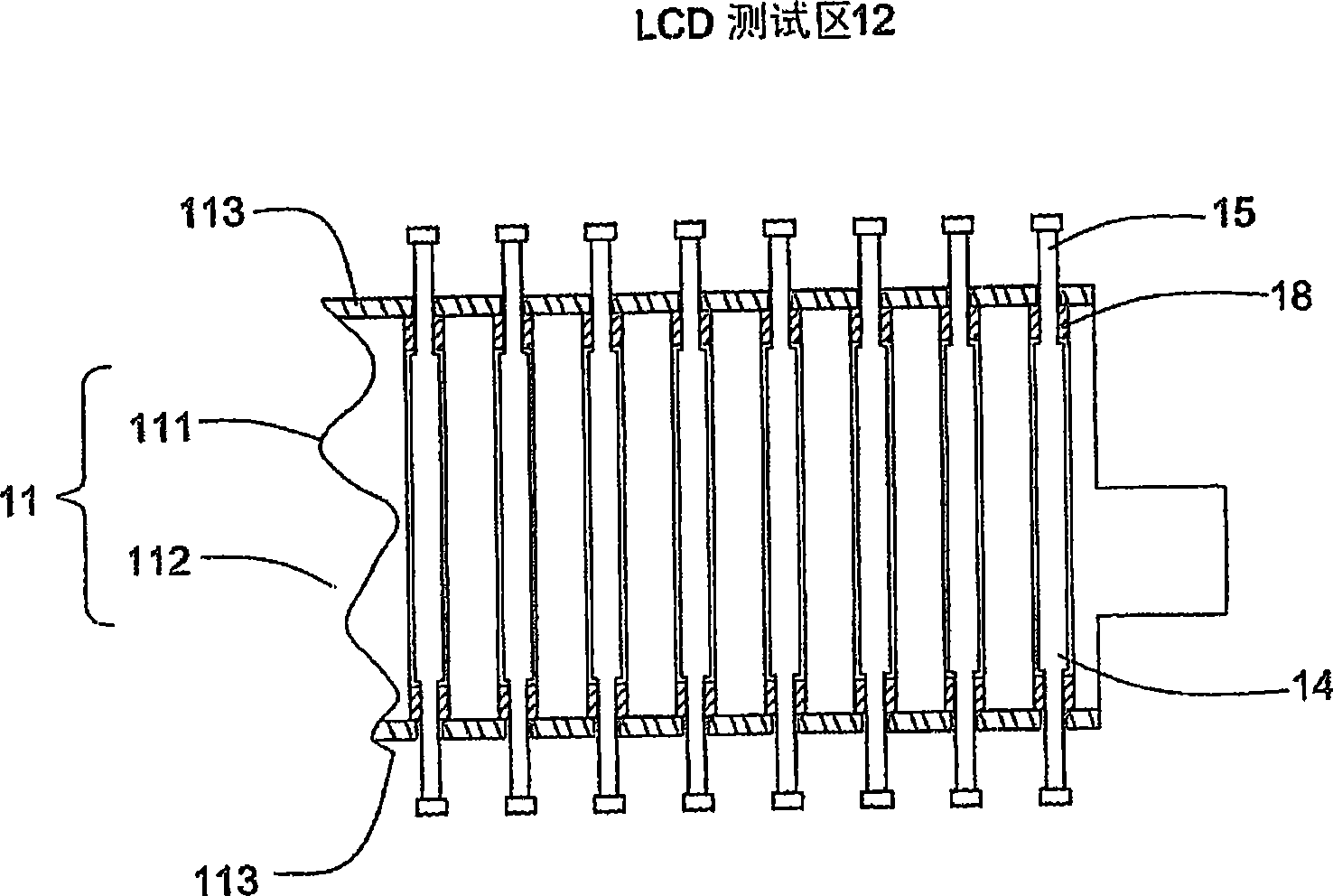

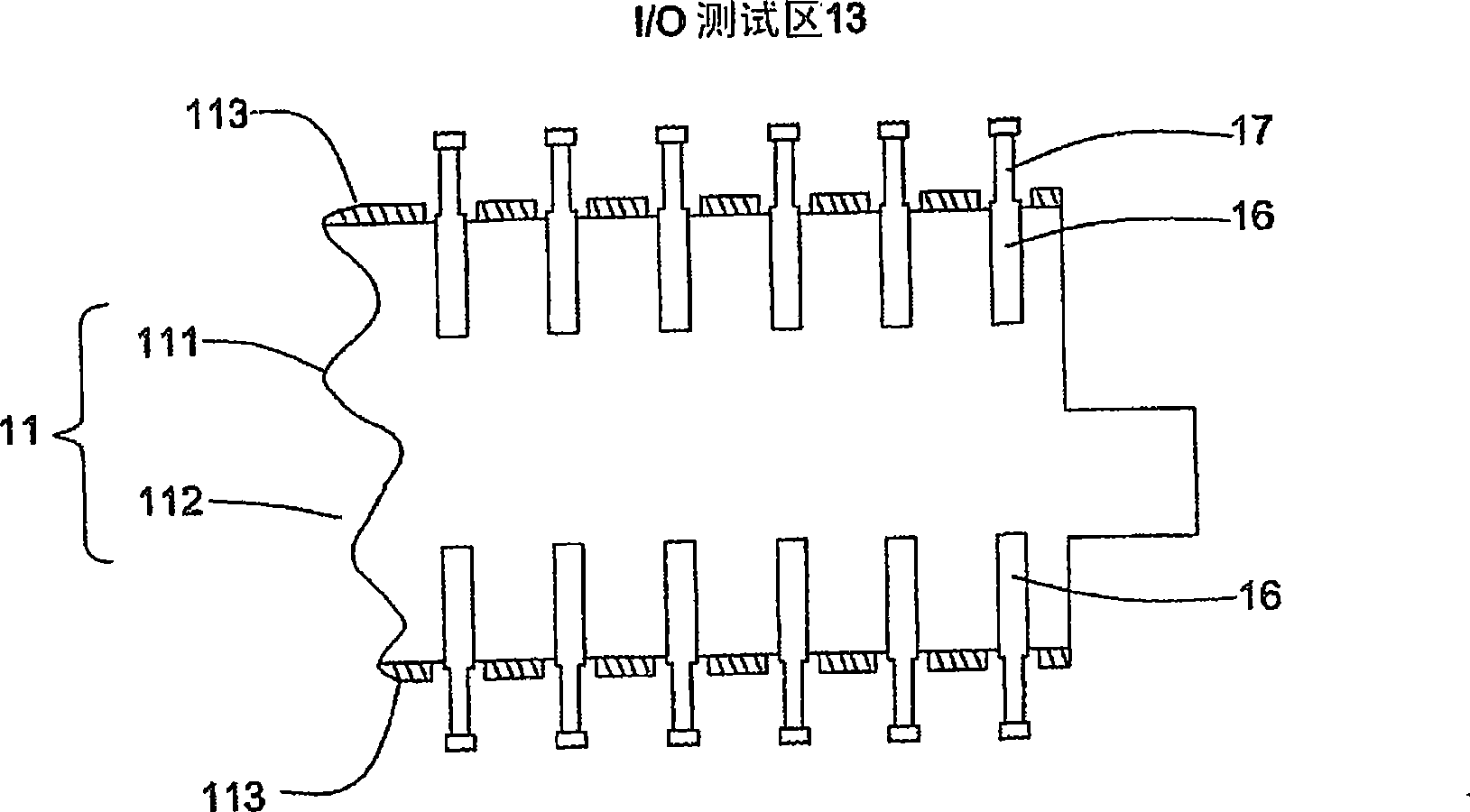

[0055] (2) Provide a wafer test seat 51 (step 52 ), which at least has a moving platform 52 , a probe tower 50 and a needle test card 53 . The motion platform 52 is used to carry a wafer 54 to be tested and provide its movement in the three axes of X-Y-Z. The needle test card 53 provides contact with the wafer 54 to be tested, and connects the electrical signal to be tested on the wafer 54 to be tested, and then performs relevant signal analysis and processing after receiving the signal through the probe tower 50 . The technical features and related structures of the probe tower 50 are as described for the probe tower 10 of the first embodiment.

[0056] (3) Provide a test head 55 (step 53 ) for correspondingly connecting to the probe ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com