Modifier for ladle deoxidation and slag formation and method for producing the same

A technology of modifier and slagging, which is applied in the field of metallurgy, can solve the problems of loss of effective reducing agent, large composition deviation, and influence on steelmaking production, etc., and achieve the improvement of melting slagging speed, fast melting slagging performance, and oxygen removal effect Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

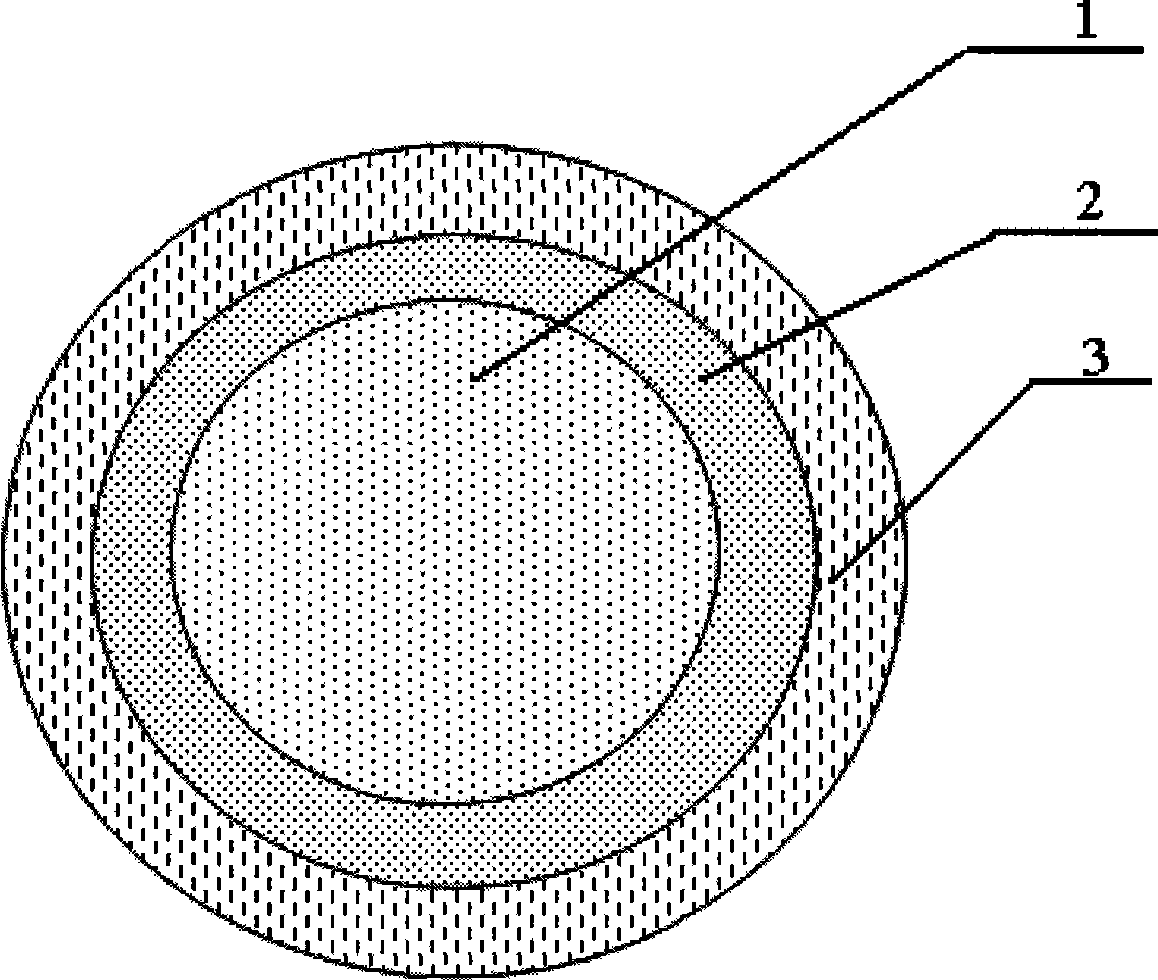

[0033] According to the total weight percentage, 40% active lime crushed to less than 0.1mm is sprayed with 15% calcium xylate solution as a binder, and φ5mm~φ8mm pellets are made on a disc granulator; φ5mm~φ8mm lime balls are placed Put it into a disc granulator containing 30% of the total weight and spray aluminum powder with a concentration of 15% calcium woodylate solution to make φ8mm~φ10mm pellets bonded with aluminum powder; then φ8mm~φ10mm surface The pellets bonded with aluminum powder are sprayed with a concentration of 15% calcium xylate solution and placed on a disc granulator filled with 18% bauxite, 10% limestone and 2% flux for final granulation, and the final granulation is φ10mm~ φ15mm pellets.

[0034] The above binders are all dissolved in alcohol with a concentration of 15% calcium xylate solution, and the dosage is 2% to 5% of the total weight.

Embodiment 2

[0036] Crush the active lime to less than 0.1mm, mix it with -180 mesh aluminum powder in the mixer for 20 minutes, spray calcium xylate solution with a concentration of 15% as a binder, and make it into φ8mm~φ10mm on a disc granulator Mixed balls of active white ash and aluminum powder, wherein 40% active white ash and 30% aluminum powder, the ball of active white ash mixed with aluminum powder is sprayed with a concentration of 15% calcium xylate solution as a binder, filled with 18% aluminum Bauxite, 10% limestone, and 2% fluxing agent are used for final granulation on a disc granulator, and the final granules are φ10mm~φ15mm pellets.

[0037] The above-mentioned binders are 15% calcium xylate solutions dissolved in alcohol, and the total dosage is 2% to 5%.

[0038] The above disc granulator has a diameter of 1.45-1.65m and a rotating speed of 900-120r / min.

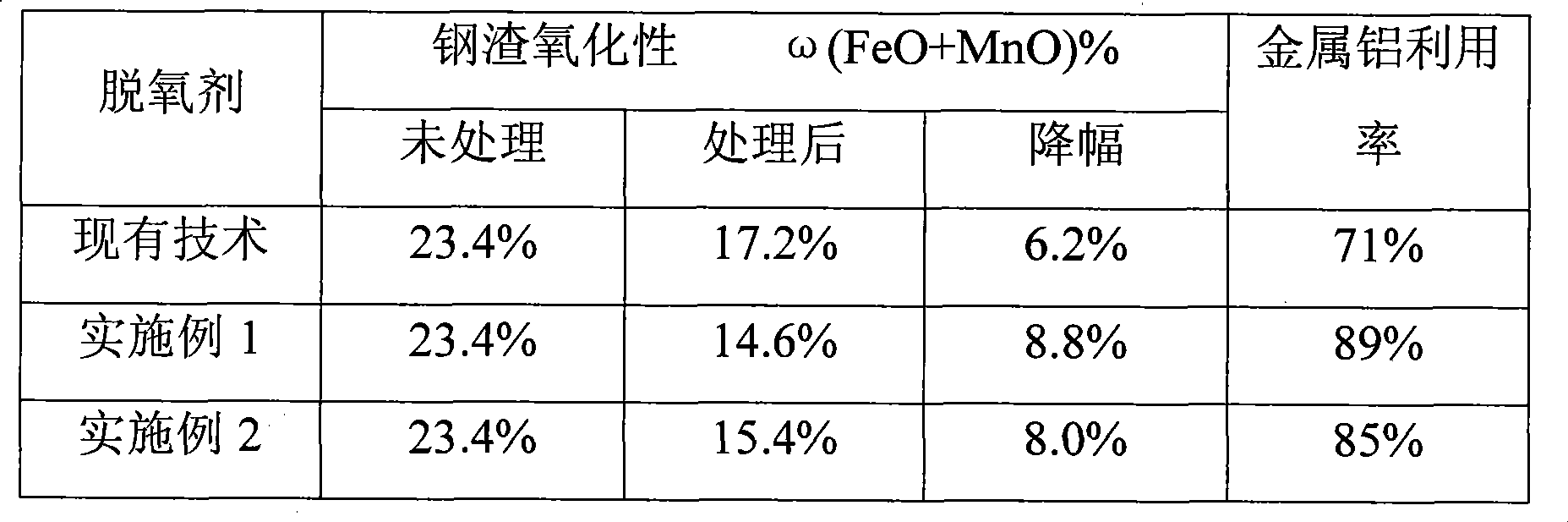

[0039] The comparison results are shown in the table below.

[0040]Comparison of deoxidation effect

[0041]

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap