Method for fermentation preparation of L-aminoacid

A technology of amino acid and fermentation medium, which is applied in the field of L-amino acid, can solve the problems that cannot be directly applied, and achieve the effect of increasing yield and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0011] Seed medium: glucose 3, corn steep liquor 3, soybean concentration 2, K 2 HPO 4 0.15, MgSO 4 ·7H 2 O 0.04, urea 0.2, adjust the pH to 7.0-7.2, and heat at 115°C for 15 minutes to sterilize.

[0012] Brevibacterium flavum ATCC 14067 was inoculated in a 5L seed tank, and cultured with shaking at 32°C for 9 hours.

[0013] Glutamic acid fermentation medium: glucose 14, molasses 0.1, Na 2 HPO 4 0.16, KCl 0.12, MgSO 4 ·7H 2 O 0.08, FeSO 4 4H 2 O 0.0002, MnSO 4 0.0002, Vitamin B 1 20mug / l. Take 6 parts of the above culture medium, each 3L, add 0.05, 0.1, 0.15, 0.2, 0.25 and 0.3 betaine hydrochloride to the fermentation broth of the 6 culture media respectively, and adjust the pH to 7.0. Put each 3L medium into a 5L fermenter, and heat at 115°C for 15 minutes to sterilize.

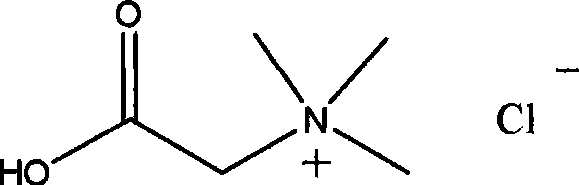

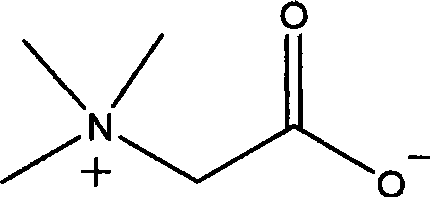

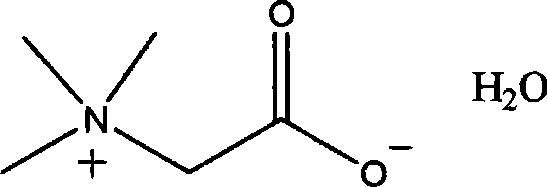

[0014] Wherein, the structural formula of betaine hydrochloride:

[0015]

[0016] Molecular formula: C 5 h 14 NO 2 Cl;

[0017] Molecular weight: 153.61;

[0018] Physical proper...

Embodiment 2

[0023] Seed medium: glucose 3, corn steep liquor 3, soybean concentration 2, K 2 HPO 4 0.15, MgSO 4 ·7H 2 O 0.04, urea 0.2, adjust the pH to 7.0-7.2, and heat at 115°C for 15 minutes to sterilize.

[0024] Brevibacterium flavum ATCC 14067 was inoculated in a 5L seed tank, and cultured with shaking at 32°C for 9 hours.

[0025] L-glutamic acid fermentation medium: glucose 14, molasses 0.1, Na 2 HPO 4 0.16, KCl 0.10, MgSO 4 ·7H 2 O 0.08, FeSO 4 4H 2 O 0.0002, MnSO 4 0.0002, Vitamin B 1 20mug / l, adjust the pH to 7.0. Take 5 parts of the above culture medium, each 3 L, put each 3 L culture medium into a 5 liter fermenter, and heat at 115° C. for 15 minutes to sterilize.

[0026] Insert 300 ml of the seeds obtained by the above-mentioned culture into each fermenter, and culture in aeration at a temperature of 34°C. During the cultivation process, ammonia water is used to adjust the pH of the culture medium to maintain it at 7.2, and at the same time, continuously a...

Embodiment 3

[0030] Seed Medium: Glucose 2.5, (NH4) 2 SO 4 0.5, KH 2 PO 4 0.1, MgSO 4 ·7H 2 O 0.05, corn steep liquor 3.5-4.0, CaCO 3 1.0, pH adjusted to 7.0-7.2, sterilized under 0.1Mpa pressure for 20 minutes.

[0031] Brevibacterium flavum ATCC 14067 was inoculated in a 5L seed tank, and cultured with shaking at 31°C for 12h.

[0032] Fermentation medium for L-lysine: Glucose 18, (NH4) 2 SO 4 50, KH 2 PO 4 0.1, KCl 0.12, MgSO 4 ·7H 2 O 0.5, corn steep liquor 0.5-1.5, L-threonine 0.4, CaCO3 4.0. Take 6 parts of the above culture medium, each 3.6 L, add 0.05, 0.1, 0.15, 0.2, 0.25 and 0.3 betaine hydrochloride to the fermentation liquid of the 6 culture media respectively, adjust the pH to 7.0-7.2, and divide each 3.6L medium was put into a 7L fermenter, and sterilized under 0.07Mpa pressure for 8 minutes.

[0033] Insert 360 ml of the seeds obtained by the above-mentioned culture into each fermenter, and culture in aeration at a temperature of 30°C. During the cultivat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com