Scale and corrosion inhibitor suitable for reclaimed water reuse system

A scale and corrosion inhibitor and system technology, applied in the field of industrial circulating cooling water treatment agent and scale and corrosion inhibitor, can solve the problem of general scale and corrosion inhibitor performance decline, scale and corrosion inhibition effect decline, scaling and corrosion. The problem of large tendency is to achieve the effect of inhibiting scale deposition, good scale and corrosion inhibition, and prolonging the service life of the equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

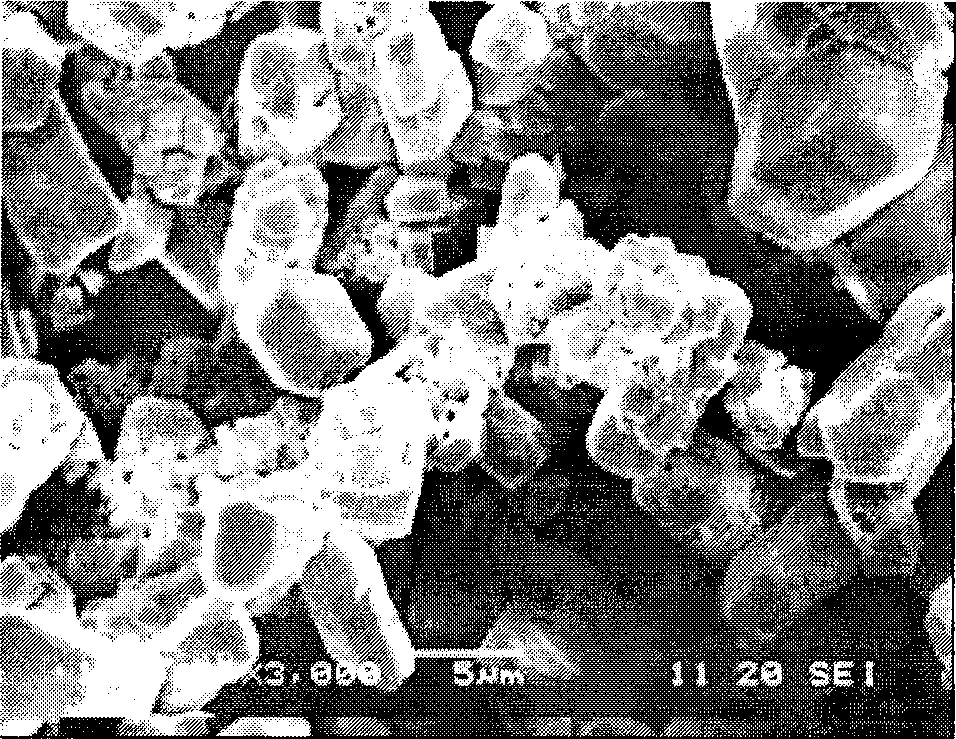

Image

Examples

Embodiment Construction

[0034] Now taking PESA100 parts as an example, the non-limiting embodiment is described as follows:

[0035] 1. 100 parts of PESA, 100 parts of PBTC, 50 parts of 1-tetradecylamine, 100 parts of EO / PO polyether with n=20, stir evenly. n is the degree of polymerization, the same below.

[0036] 2. 100 parts of PESA, 200 parts of PBTC, 100 parts of 1-hexadecylamine, 200 parts of EO / PO polyether with n=25, and stir evenly.

[0037] 3. 100 parts of PESA, 120 parts of PBTC, 65 parts of dioctylamine, 140 parts of EO / PO polyether with n=30, stir evenly.

[0038] 4. 100 parts of PESA, 180 parts of PBTC, 80 parts of 1-hexadecylamine, 120 parts of EO / PO polyether with n=22, and stir evenly.

[0039] 5. 100 parts of PESA, 150 parts of PBTC, 70 parts of trihexylamine, 150 parts of EO / PO polyether with n=25, stir evenly.

[0040] 6. 100 parts of PESA, 145 parts of PBTC, 75 parts of dioctylamine, 155 parts of EO / PO polyether with n=30, stir evenly.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| corrosion rate | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com