Method for implementing shortcut nitrification in complete nitrification biological denitrification system at normal temperature

A full-process nitrification and biological denitrification technology, applied to the field of short-range nitrification in the full-process nitrification biological denitrification system at room temperature, can solve problems such as weakening the adverse effects of low temperature during the start-up period, and achieve a strong guiding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

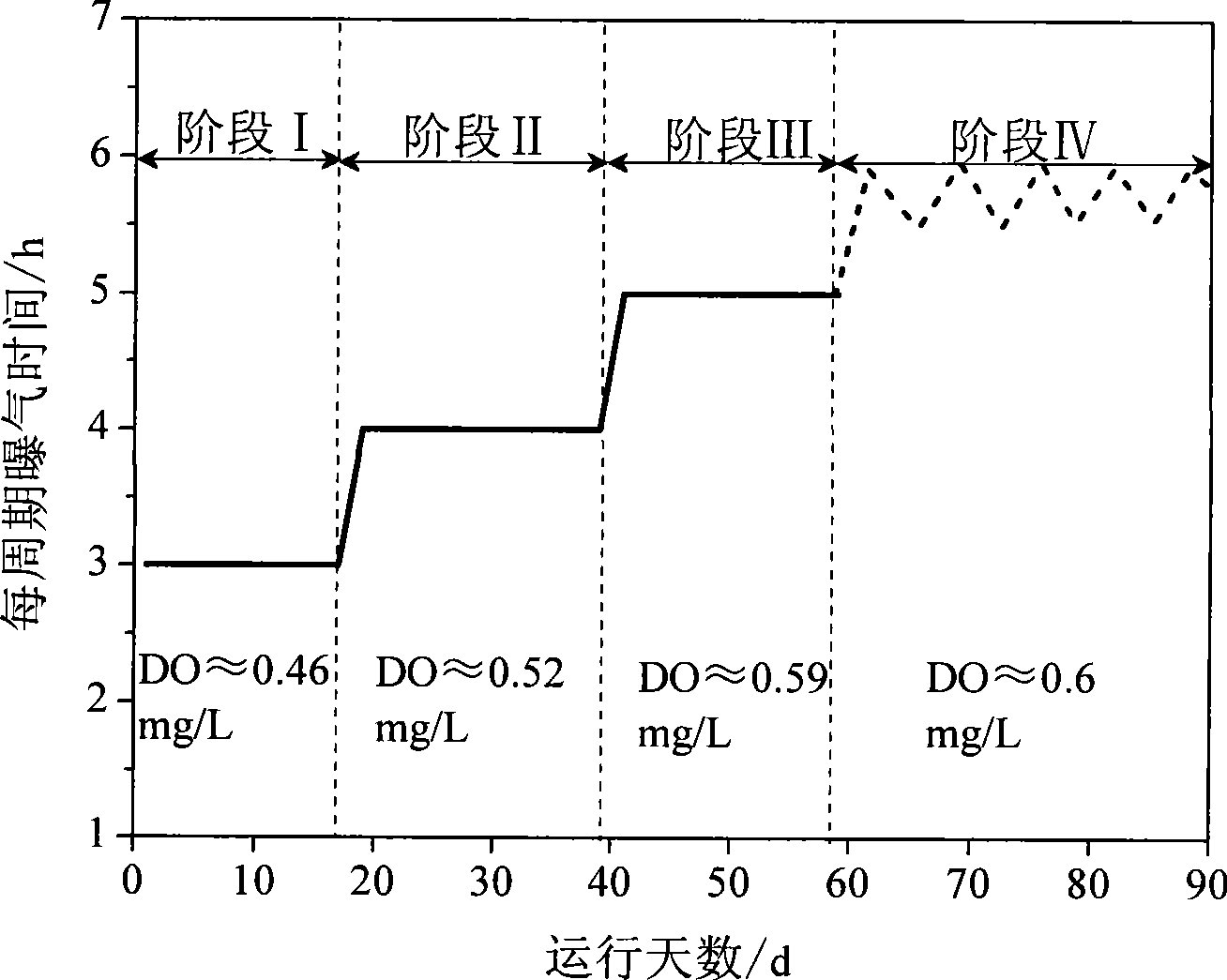

[0028] The specific embodiment of the present invention is: (see attached figure 1 )

[0029] Phase I adopts the aeration mode of constant air supply and oxygen-limited aeration to keep the dissolved oxygen in the system at a low level, and the average DO level is 0.5-0.8mg / L. The sludge age is controlled at 50-60 days through regular sludge discharge at the end of each cycle of aerobic phase. The aeration time is regularly controlled in a short cycle, and the aeration time of each cycle is 3 hours. The water quality changes of the influent and effluent are measured by the routine water quality monitoring method in the laboratory. After the effluent NO 2 - -N / NO x - -N rises to 30-60% and enters stage II. At the same time, mud samples are collected periodically for FISH testing to determine the proportion of AOB and NOB in the total flora, providing molecular biological evidence for the dynamic changes of the system flora structure;

[0030] Phase II adopts the aeration m...

Embodiment 1

[0034] A 11L SBR reactor was used for the test, and the sewage used was taken from the actual domestic sewage in the residential area, which is a typical low C / N wastewater. Its water quality index is: COD=121~416mg / L, NH 4 + -N=54~78mg / L, NO 3 - -N=0~0.21mg / L, NO 2 - -N=0~0.09mg / L, pH=7.46~8.01, total alkalinity=455.6~556mg / L (CaCO 3 Count), C / N is 1.89~2.51. The inoculum sludge was taken from the return sludge of the secondary settling tank of a sewage treatment plant in Beijing, which is a full-process nitrification sludge. FISH test showed that the proportion of AOB to the total bacterial flora was 1.98%, and NOB was 8%. The water temperature in the reactor is controlled at (19°C ± 1°C) by the temperature control device, and the sludge age is controlled to 50 days by regular sludge discharge at the end of the aerobic stage of each cycle.

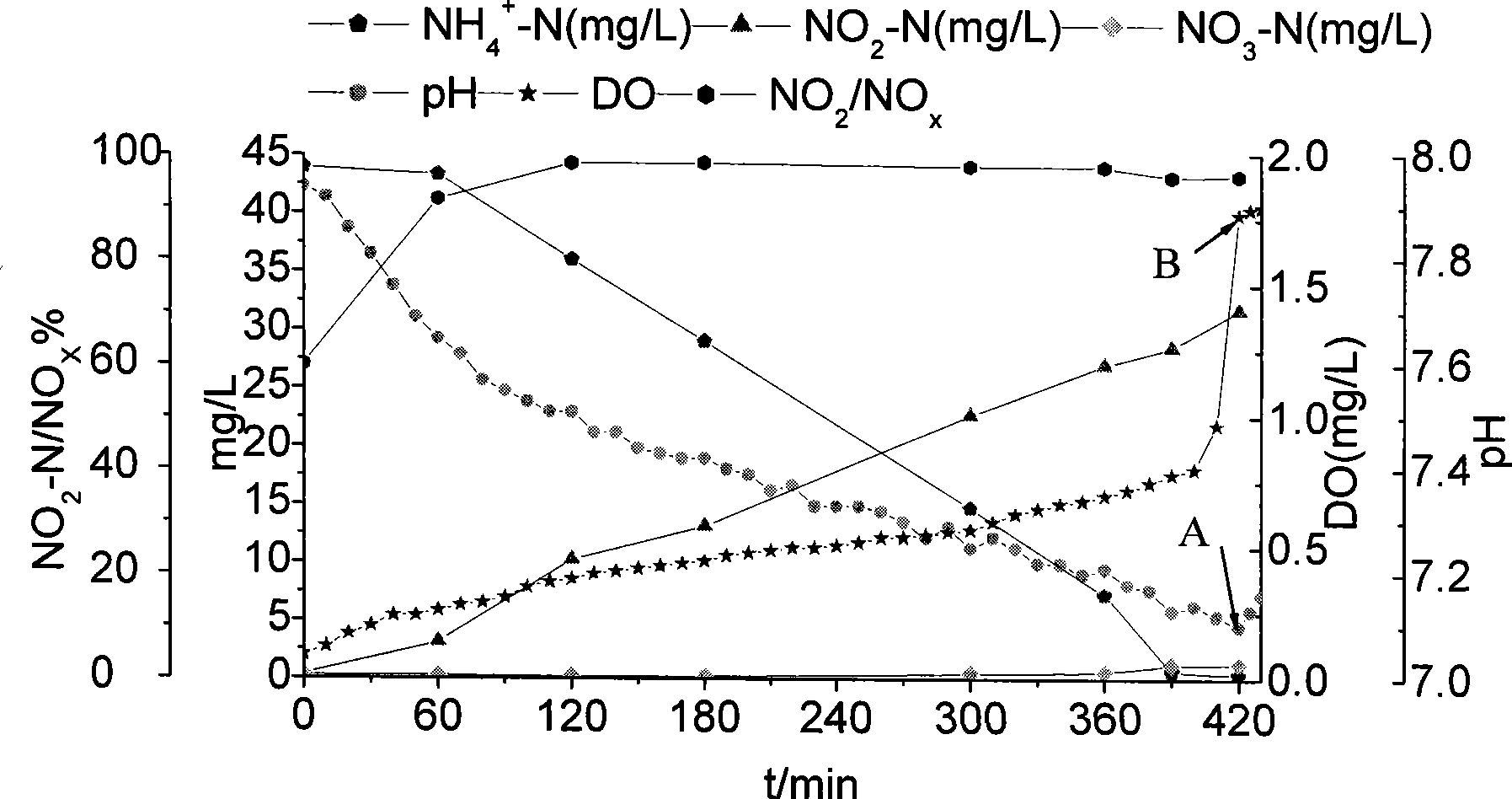

[0035] (1) Stage I: The average level of DO is controlled by oxygen-limited aeration to 0.46mg / L, and the aeration time per cycl...

Embodiment 2

[0040] A 6.5L SBR reactor was used for the test, and the test water was domestic sewage from the family area of Beijing University of Technology. Its water quality index is: COD=101~236mg / L, NH 4 + -N=34~68mg / L, NO 3 - -N=0~0.17mg / L, NO 2 - -N=0~0.04mg / L, pH=7.24~8.31, total alkalinity=405.6~581mg / L (CaCO 3 Count), C / N is 1.54 ~ 2.89. The inoculum sludge was taken from the secondary settling tank sludge of a pilot denitrification reactor. The denitrification performance was good, and it belonged to the whole process of nitrification sludge. FISH test showed that the proportion of AOB to the total bacterial flora was 4.98%, and NOB was 9.4%. Without temperature control, the water temperature ranges from 8.2°C to 16.7°C, and the sludge age is controlled to 65 days through sludge discharge.

[0041] (1) Stage I: The average level of DO is controlled by oxygen-limited aeration to 0.34mg / L, and the aeration time per cycle is 3h. Run for 22 days NO 2 - -N / NO x - -N inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com