Apparatus and method for machining bevel gears in a pitching method with complete pitch error compensation

一种分度误差、伞齿轮的技术,应用在分度法加工伞齿轮的装置领域,能够解决不令人满意、改变等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Related terms used in this specification are also used in related publications and patents. However, it should be noted that these terms are used only for better understanding of the present invention. The idea according to the present invention and the protection scope of the claims are not limited by the interpretation of these specifically selected terms. The invention can be transferred to other systems and / or fields without further measures. These terms can be applied to other fields accordingly.

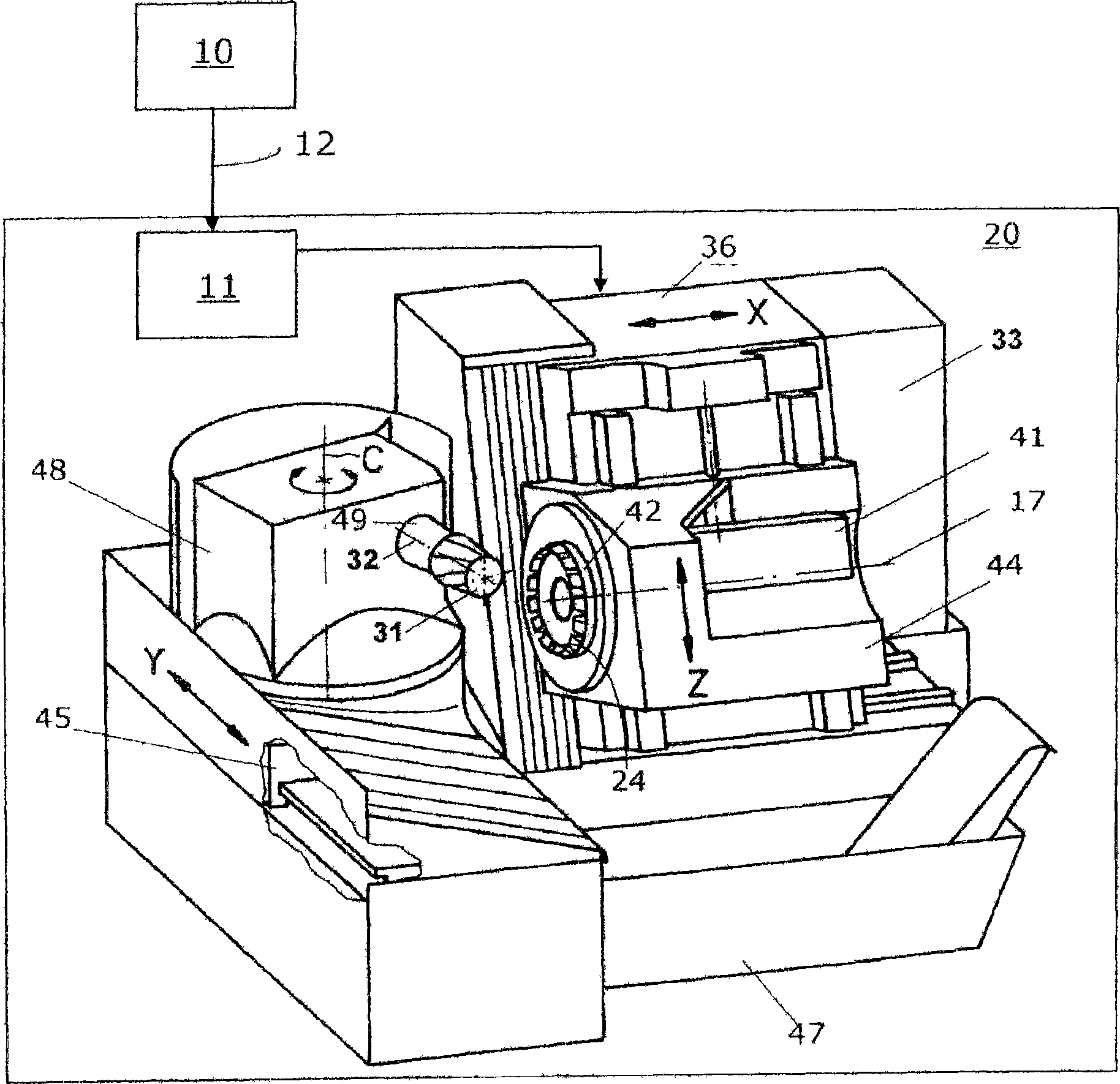

[0041] figure 1 Shown is a first device 20 of the present invention. The first device 20 according to the invention may correspond completely or partially to a CNC machine for the production of spiral bevel gears as described in patent application DE 196 46 189 C2. The first device has a drive motor 41 which rotates the face milling cutter 24 about its axis of rotation 17 . The electric motor 41 and the face milling cutter 24 are located on a first slide 44 which is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com