Integrated high voltage pack for xenon lamp

A xenon lamp and high-voltage package technology, which is applied to electrical components, lighting devices, light sources, etc., can solve the problems of difficult promotion and use, difficult installation, and insufficient compactness, and achieves the effect of beautiful appearance, compact size, and elimination of high-voltage loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

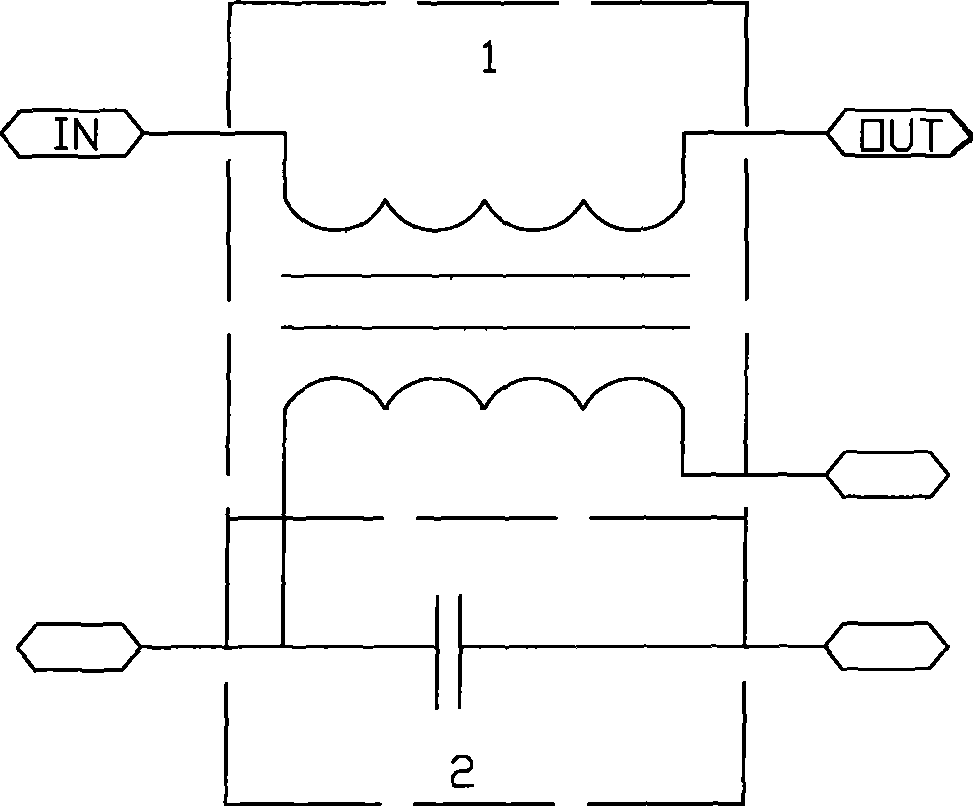

[0013] Such as figure 1 , figure 2 As shown, the integrated xenon lamp high-voltage package of the present invention is arranged in the xenon lamp supercharging circuit and connected with the xenon lamp ignition capacitor 2. Since the manufacturing process of the two is very close, the one high-voltage package 1 and one ignition capacitor 2 can be wrapped and solidified by epoxy resin 3, so that the whole high-voltage component part can be made small in size, light in weight, rich in appearance and exquisite in appearance, and can be easily installed on the lamp holder to achieve There is no high voltage exposure; the circuit is input from both sides to IN and OUT, and the output terminal OUT of the high voltage package is connected to the xenon lamp.

[0014] The high-voltage package can also be directly installed and fixed with the xenon lamp tube as a whole, eliminating the need for high-voltage lead wires, eliminating the high-voltage loss of the high-voltage lead wires,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com