Knocking type deicer for power transmission line

A technology for transmission lines and deicers, which is applied in the installation of cables, electrical components, overhead installations, etc., and can solve the problems of complex milling equipment, slow milling speed, and inconvenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

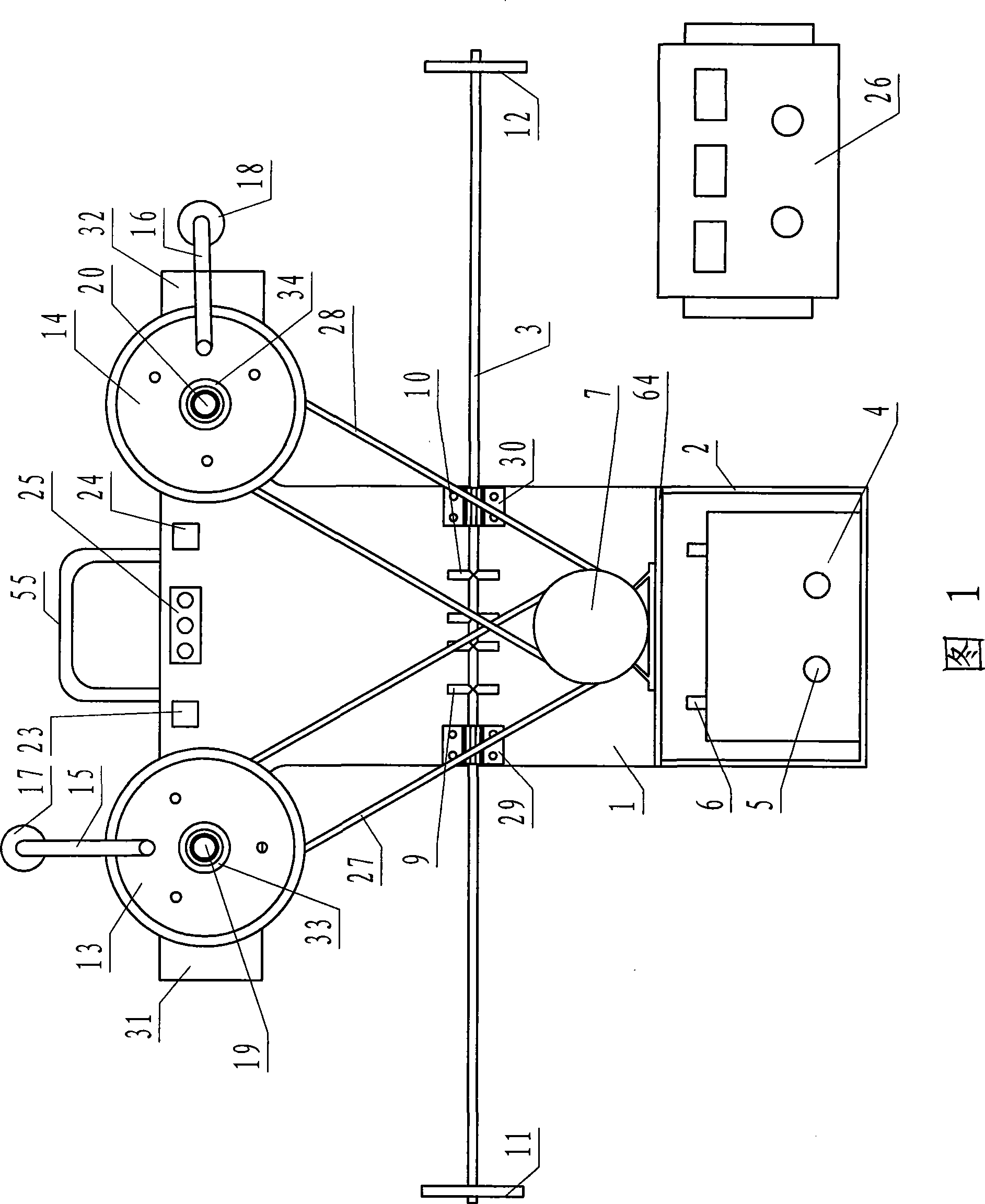

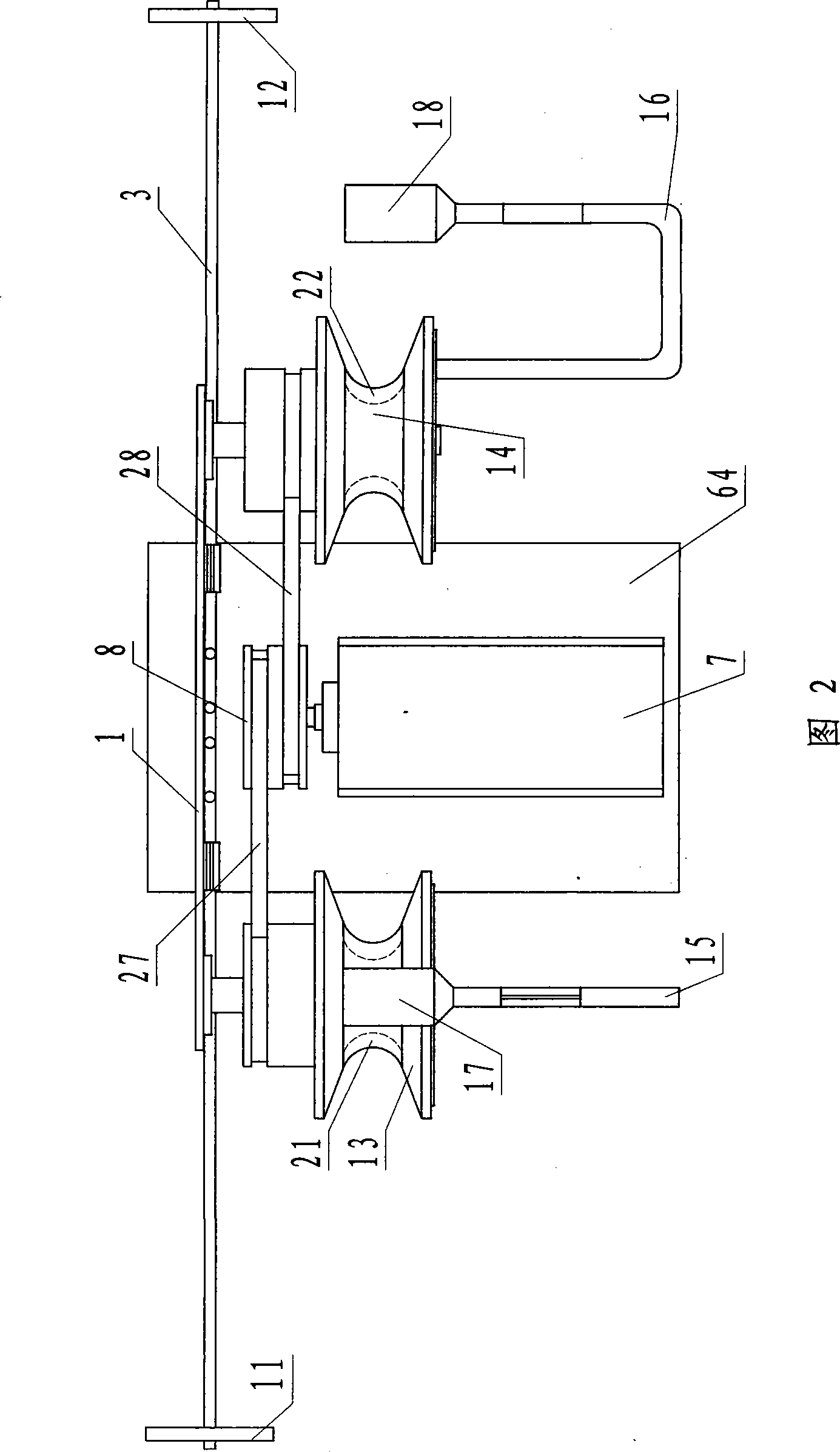

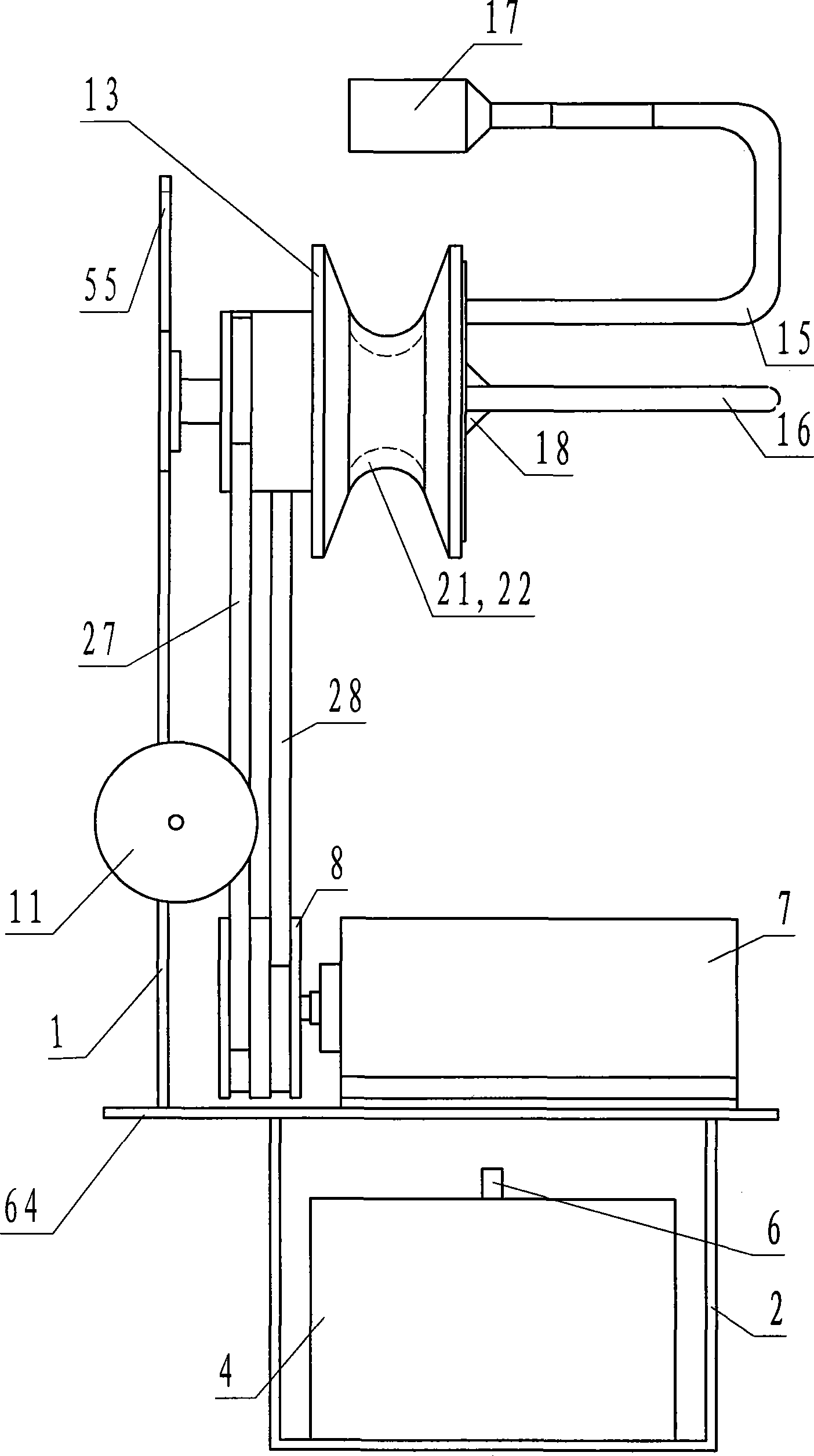

Image

Examples

Embodiment 1

[0041] The method of use is as follows:

[0042] Deicer, remote control receiver, remote control transmitter, sensor, battery power supply, and hot air balloon are all in a quasi-working state;

[0043] Hang the deicer with the hot air balloon;

[0044] Start the hot air balloon and use the control rope to control the hot air balloon;

[0045] Driven by the hot air balloon, the de-icer rises to a specified height;

[0046] Pull the hot air balloon with a rope to drive the left and right wheels of the deicer to align with the power transmission cable, so that the deicer is adsorbed on the cable;

[0047] Operate the hot air balloon and de-icer to loosen the rope, but do not disconnect;

[0048] The ground remote control transmitter instructs the deicer to start working;

[0049] The deicer knocks reciprocatingly to de-icer and automatically reverses direction;

[0050] After the deicing is completed, turn off the deicer motor, tighten the hot air balloon rope, separate the deicer f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com