Network control method of induction machine and device thereof

An induction motor and network control technology, applied in the direction of electrical program control, comprehensive factory control, comprehensive factory control, etc., can solve problems such as difficult to meet, limited transmission distance, etc., achieve fast dynamic response, high power factor, and convenient network reloading structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

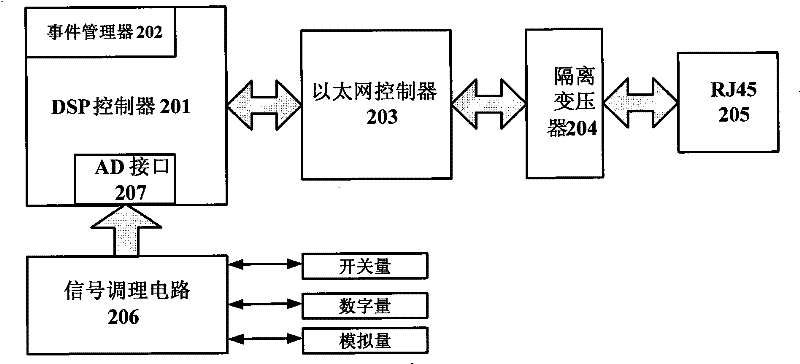

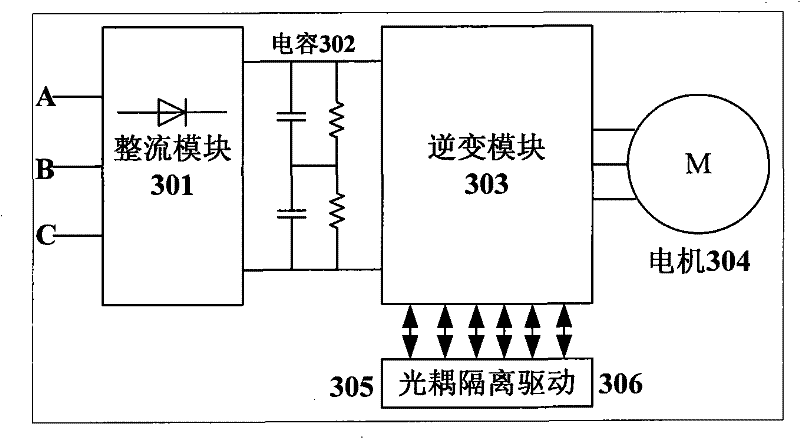

[0067] 1. The induction motor in the network control device is driven by an all-digital control frequency converter, and the control system adopts an advanced embedded microcontroller / processor TMS320F2812 and its supporting software CCS3.1, so all physical parameters during the operation of the motor can be networked Intelligent and intelligent real-time control, all-digital AC motor control adopts space vector pulse width modulation technology SVPWM, so that the three-phase AC asynchronous induction motor can achieve high-efficiency operation. The specific implementation method is:

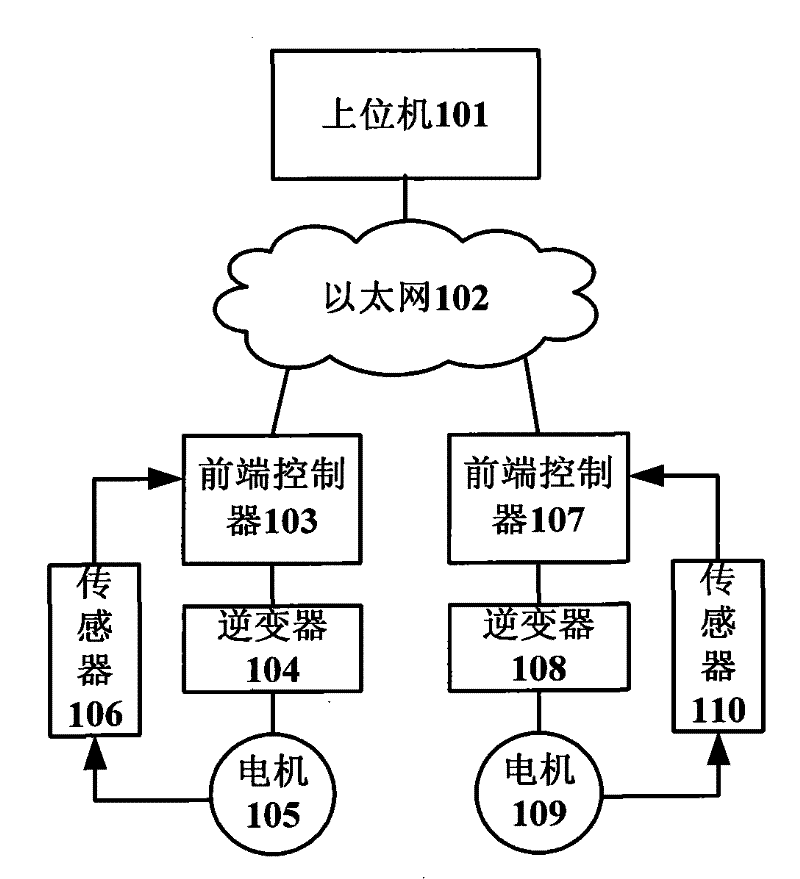

[0068] figure 1 It shows the structural diagram of the induction motor network control method, which consists of the following parts: upper computer 101 , Ethernet 102 , front-end controller 103 , frequency converter 104 , motor 105 and sensor 106 . Wherein the upper computer 101 is an ordinary PC, the upper computer 101 communicates with the front-end controller 103 through the Ethernet 102, a...

Embodiment

[0082] A network control method and device for an induction motor, as attached figure 1 As shown, only one inverter-motor system is connected to the Ethernet. The device includes a PC, the Ethernet transmission medium adopts ordinary network cables, the upper computer and the front-end controller are connected through the communication interface RJ45, the main controller of the front-end controller adopts TMS320F2812, the Ethernet controller is CS8900, and the frequency converter-motor system adopts ordinary The asynchronous motor is driven by an all-digital control frequency converter. The motor model is a domestic YZR90 three-phase squirrel-cage Y-connected asynchronous motor. The ratings are as follows:

[0083] Rated power: P N =550W

[0084] Rated voltage: U N =220V (effective value of line voltage)

[0085] Rated current: I N =2.3A

[0086] Rated speed: n N =1450rpm

[0087] Rated torque:

[0088] Number of pole pairs: n p = 2

[0089] as attached Figure 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com