Deep hole blasting process in frost weathering bedrock segment

A deep hole blasting and bedrock technology, applied in blasting and other directions, can solve the problems of high labor intensity of workers, high consumption of blasting materials, slow cycle progress, etc., to ensure construction safety and quality, low labor intensity of workers, and reduced construction costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

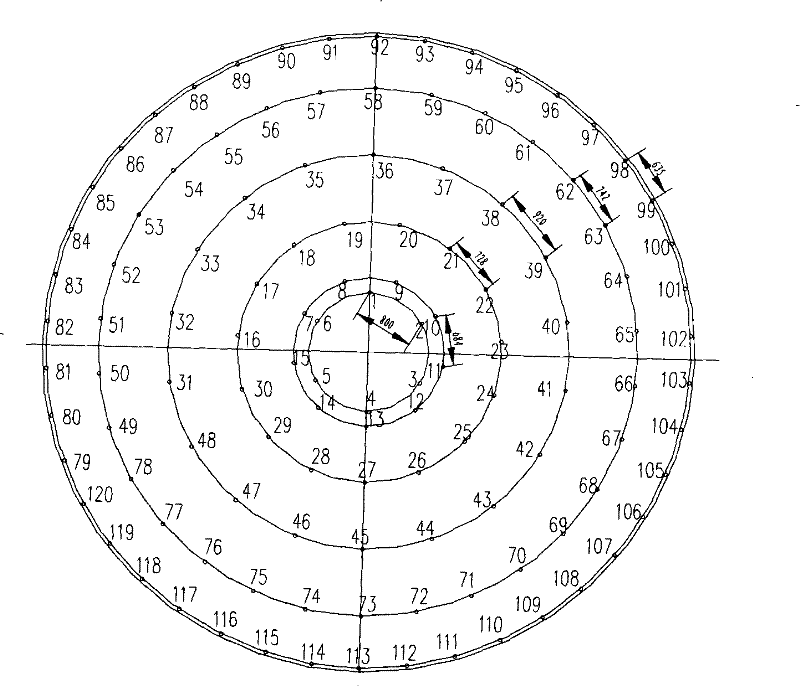

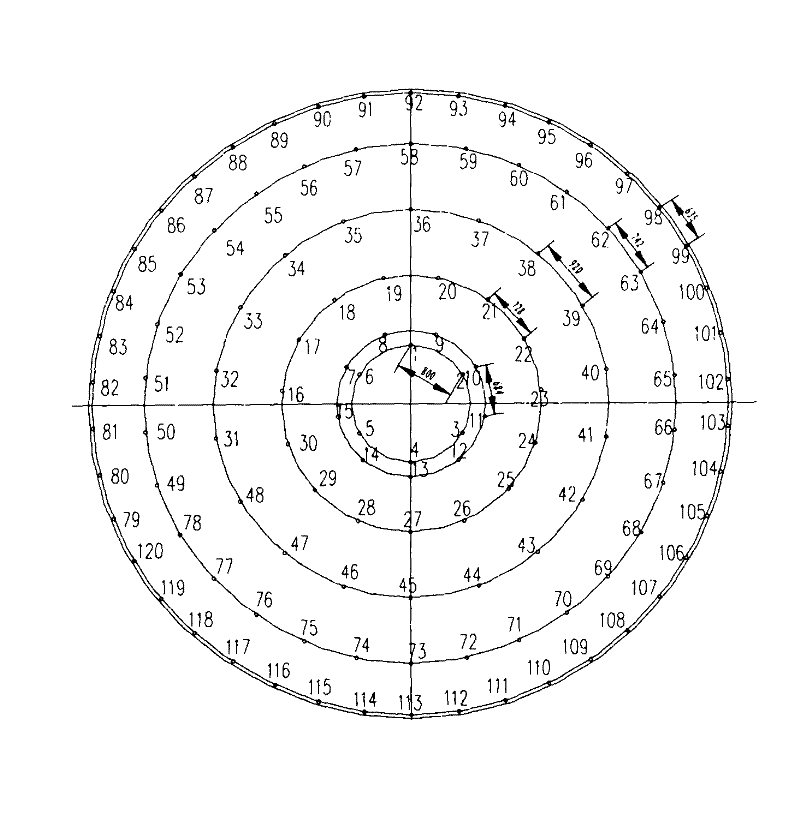

[0025] With reference to the accompanying drawings, a medium-deep hole blasting process for freezing and weathering bedrock sections, the process steps are: ①Draw the blast hole coordinate position diagram, number each blast hole, ②Determine the diameter and depth of each blast hole, ③According to each The coordinate position of the blast hole and the specified diameter and depth are drilled. ④Determine the charge uncoupling coefficient of each blast hole, determine the diameter of the explosive coil, ⑤Determine the length of the explosive coil according to the amount of explosive in each blast hole, ⑥ Fill the explosives according to the number of explosives used in each blasting hole, ⑦install a detonator into each blast hole, ⑧determine the detonator segment number according to the blasting sequence of each blasting hole, and use the detonator detonating wire for each detonator according to the segment number of each detonator Connect with the detonator, ⑨block the blasting h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com